Jul . 26, 2025 01:01 Back to list

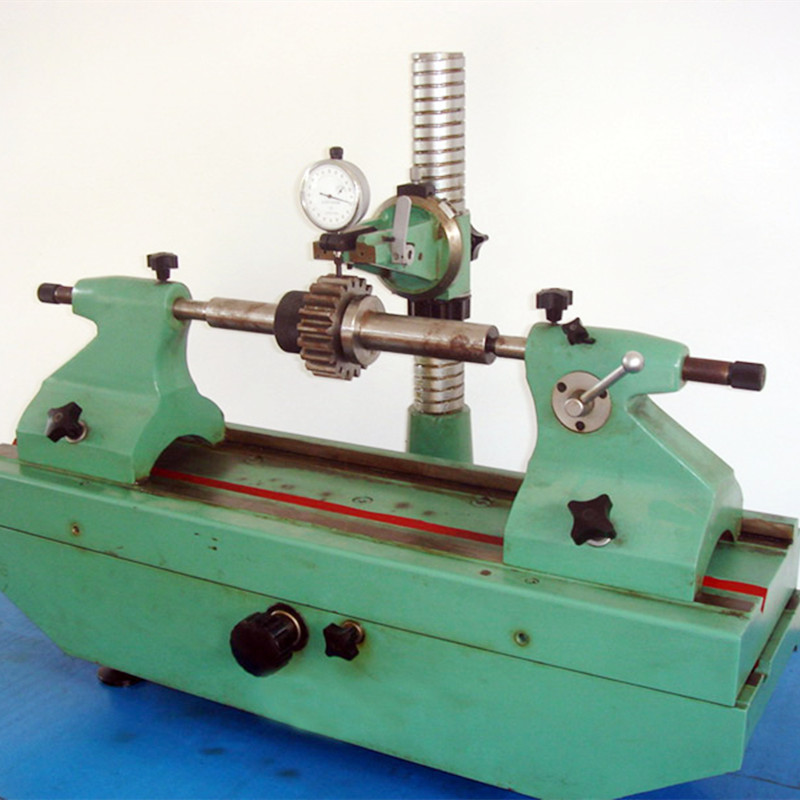

High Precision Runout Tester for Industrial Gauge Measurement

About Storaen (Cangzhou) International Trading Co.

Official Website: https://www.strmachinery.com

Product: Runout Tester

Application: For radial runout measurement in shaft parts, cylinders, rotors, and precision mechanics.

Profile: Storaen is a leading supplier of gauge measurement tool solutions, catering to automotive, aerospace, and machining sectors. The company is renowned for delivering products that merge expertise, innovation, and trustworthiness, backed by years of export experience.

Address: No.17, Building 11, Hardware Building Material City, Botou, Cangzhou City, Hebei Province, China

The demand for highly accurate industrial measurement tools such as the runout tester has significantly surged, especially in precision-driven manufacturing environments.

As per Quality Magazine, embracing advanced precision gauge technologies enables manufacturers to maintain global competitiveness by achieving sub-micron tolerances and ensuring traceable data.

In the context of Industry 4.0 and smart manufacturing, investing in accurate level measurement tool instruments has become non-negotiable for quality assurance and minimization of defective rates.

Digitalization, wireless integration, and real-time analytics are reshaping the scope and application fields of measurement devices.

Source: Quality Magazine, The Power of Measurement Data

The runout tester is a specialized pendulum-type instrument engineered to measure the radial runout error of shaft components and similar cylindrical workpieces. It utilizes two precision thimbles for part positioning, enabling accurate and repeatable measurements as the workpiece is rotated. The sensitive probe captures minute variations in the radial direction to determine deviation and ensure part uniformity.

Key Features:

- High-resolution digital and analog readouts

- Rugged construction for workshop environments

- Easy to calibrate and operate

- Wide measuring range and versatile fixture options

- Suitable for a variety of materials and diameters

| Parameter | Standard Model | Advanced Model | High-Precision Model |

|---|---|---|---|

| Measuring Range | 0-50 mm | 0-100 mm | 0-200 mm |

| Resolution | 1 μm | 0.5 μm | 0.1 μm |

| Repeatability | ≤2 μm | ≤1 μm | ≤0.5 μm |

| Runout Error Detection | Radial, Axial | Radial, Axial | Radial, Axial |

| Fixture Diameter | 6-80 mm | 6-120 mm | 6-200 mm |

| Data Output | Analog | Digital/Analog | Digital/Analog/USB |

| Material | Steel/Aluminum | Steel/Aluminum | Stainless Steel |

- Automotive Manufacturing: Quality assessment of crankshafts, camshafts, bearings, and gearboxes.

- Aerospace Engineering: High-reliability precision gauge measurements for turbine shafts and sensitive rotor parts.

- General Machinery: Routine check of spindles, rollers, and drive axles in high-precision equipment.

- Maintenance Workshops: Essential for detecting latent defects in rotating assemblies.

- Metrology Labs: Reference-grade testing for certification and R&D.

- Heavy Industry: On-site level measurement tool for large shaft and cylinder alignments.

- EEAT Commitment: Products are supported by expert engineers and adhere to strict international standards.

- Authoritative Performance: Field-proven by top-tier automotive and aerospace clients globally.

- Trustworthy Experience: Decades of export and technical support.

- Comprehensive Portfolio: Solutions for gauge, runout, and level measurement tool requirements.

- Full Service: From guidance to installation and after-sales, plus fast technical response.

- The Power of Measurement Data, Quality Magazine

- Why Runout Matters, Modern Machine Shop

- Measurement of Shifted Runout (ResearchGate)

- ISO 1101:2017, Geometrical Product Specifications

- Surface Runout Measurement Techniques, Scientific Reports

- Precision in Measurement, Anesthesiology, ASA

- Global Metrology Community Forums

For more details, please visit their official product page: runout tester

This is the last article

-

Heavy Duty Knife Gate Valve PerformanceNewsJul.25,2025

-

Choosing Between Gate and Globe Gate Valves for Optimal PerformanceNewsJul.25,2025

-

Cast Iron Y Strainer DurabilityNewsJul.25,2025

-

Ball Style Check Valve MaintenanceNewsJul.25,2025

-

Types of Strainer in Piping SystemsNewsJul.25,2025

-

The Role of Master Ring Gage in Quality Control SystemsNewsJul.25,2025

Related PRODUCTS