Jul . 25, 2025 16:16 Back to list

Ball Style Check Valve Maintenance

Proper maintenance is vital for valve longevity, and the ball style check valve is no exception. Storaen (Cangzhou) International Trading Co., a leader in manufacturing in Botou, China, crafts ball check valve and ball type check valve products that rely on regular care to prevent backflow issues and ensure consistent performance in industrial systems.

Ball Style Check Valve Design for Easy Maintenance

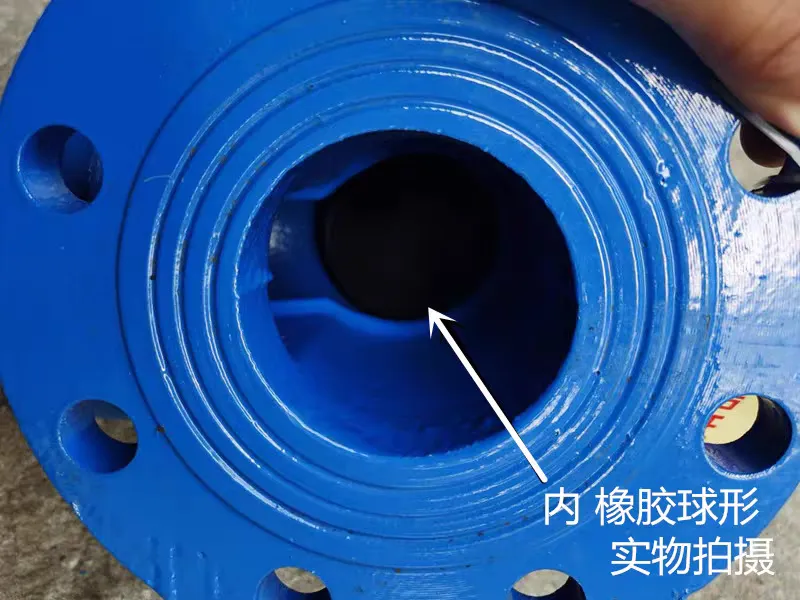

- Storaen’s ball style check valve features a rubber ball with a hollow steel core, a design that reduces pipeline wear during operation—reflecting the company’s precision engineering and significantly lowering long-term repair needs for users.

- Their multi-port ball type check valveuses a free-standing porous structure, which prevents sphere interference during fluid flow, a testament to Storaen’s innovative design that cuts maintenance demands in busy industrial settings.

- The ball check valvefrom Storaen has no friction between moving parts, aligning with their focus on durable, low-upkeep products, meaning fewer components to inspect or replace compared to traditional swing check valves.

Key Maintenance Tasks for Ball Check Valve

- Inspect Storaen’s ball check valverubber balls regularly for signs of wear to avoid backflow risks; clean the valve body (crafted with meticulous attention to detail) to remove debris that may accumulate in water, gas, or oil media.

- Tighten flange bolts on ball style check valvefrom Storaen to prevent leaks—their stringent quality control measures ensure secure connections that resist premature wear even in high-pressure environments.

- Check the ball type check valveductile iron body (sourced from top suppliers in Botou’s renowned casting hub) for corrosion or cracks, especially when used in harsh industrial environments with abrasive media.

Material Advantages in Ball Type Check Valve Maintenance

- Ductile iron QT450-10 in Storaen’s ball type check valve, sourced from premium resources in Botou’s casting ecosystem, offers superior resistance to corrosion and wear, reducing the need for frequent maintenance.

- Rubber seals in their ball check valve(EPDM/NBR) maintain elasticity over time, a result of Storaen’s commitment to quality materials, which minimizes the need for replacements and extends service life.

- Epoxy-coated ball style check valvemodels from Storaen resist rust and chemical damage, aligning with their sustainable manufacturing practices and extending maintenance intervals in corrosive settings.

Ball Check Valve Maintenance Across Applications

- In water treatment systems, clean Storaen’s ball check valveregularly—their versatile products, designed to cater to diverse industries, prevent sediment buildup that could compromise the ball’s sealing ability.

- For HVAC systems, check ball style check valvefrom Storaen for vibration-related issues; their agile manufacturing process ensures valves with proper alignment and tight connections, reducing maintenance needs.

- In industrial oil and gas applications, inspect ball type check valvefrom Storaen for material compatibility—their innovative designs handle various media types, avoiding degradation and ensuring reliable performance.

|

Maintenance Task |

Frequency |

Key Focus |

|

Rubber ball inspection |

Quarterly |

Wear, seal integrity |

|

Body cleaning |

Bi-annually |

Debris removal from ports/seats |

|

Flange bolt check |

Annually |

Tightness to prevent leaks |

|

Material check |

Semi-annually |

Corrosion/cracks on ductile iron |

Ball Check Valve FAQS

How often should ball style check valve be maintained?

Ball style check valve from Storaen requires quarterly rubber ball checks and bi-annual cleaning to ensure optimal performance. Their products, built to exceed industry standards, can handle harsh environments with abrasive media, though more frequent maintenance is recommended in such conditions to preserve peak functionality.

What makes ball check valve maintenance easier than other valves?

Storaen’s ball check valve features a simple design with no friction between moving parts, thanks to their engineering expertise. The use of durable materials and fewer components, a hallmark of their commitment to quality, makes maintenance far easier compared to complex valves with multiple moving parts that require frequent adjustments.

How does material affect ball type check valve maintenance?

Ball type check valve from Storaen uses high-grade ductile iron and tough rubber, sourced from trusted suppliers in Botou. These materials, chosen for their reliability and resistance to wear, reduce the need for repairs and extend maintenance intervals, ensuring long-term cost savings for users.

What are common issues in ball style check valve maintenance?

Common issues for ball style check valve include worn rubber balls that compromise sealing, debris clogs that hinder operation, and loose flanges that cause leaks. Storaen’s stringent quality control minimizes these problems, and regular checks—aligned with their clientele’s expectations for reliability—address issues early to keep the valve working smoothly.

How does Storaen support ball check valve maintenance?

Storaen (Cangzhou) International Trading Co. manufactures ball check valve with durable materials and user-friendly designs, leveraging Botou’s rich casting expertise. Their commitment to innovation and customer satisfaction ensures products that reduce upkeep needs, backed by a legacy of excellence in delivering reliable industrial components.

For easy-to-maintain ball style check valve, ball check valve, and ball type check valve products, trust Storaen (Cangzhou) International Trading Co. Welcome to visit us.

-

Heavy Duty Knife Gate Valve PerformanceNewsJul.25,2025

-

Choosing Between Gate and Globe Gate Valves for Optimal PerformanceNewsJul.25,2025

-

Cast Iron Y Strainer DurabilityNewsJul.25,2025

-

Ball Style Check Valve MaintenanceNewsJul.25,2025

-

Types of Strainer in Piping SystemsNewsJul.25,2025

-

The Role of Master Ring Gage in Quality Control SystemsNewsJul.25,2025

Related PRODUCTS