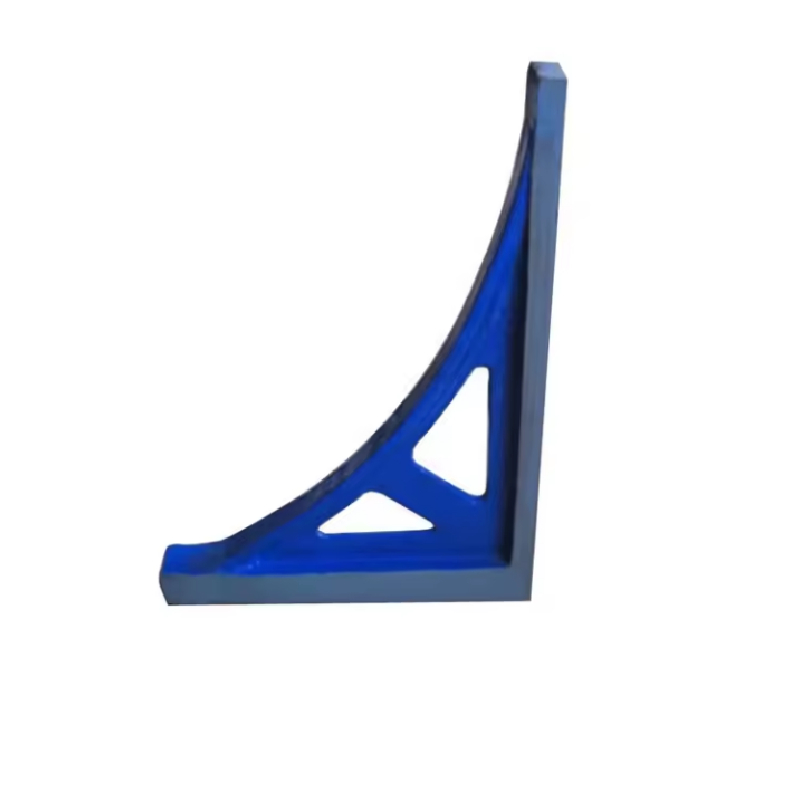

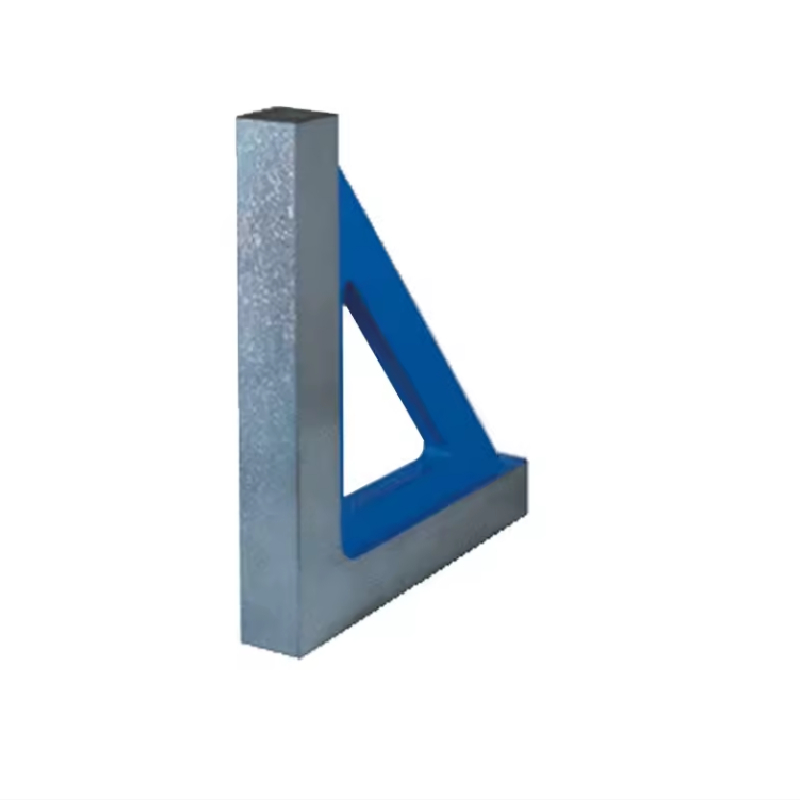

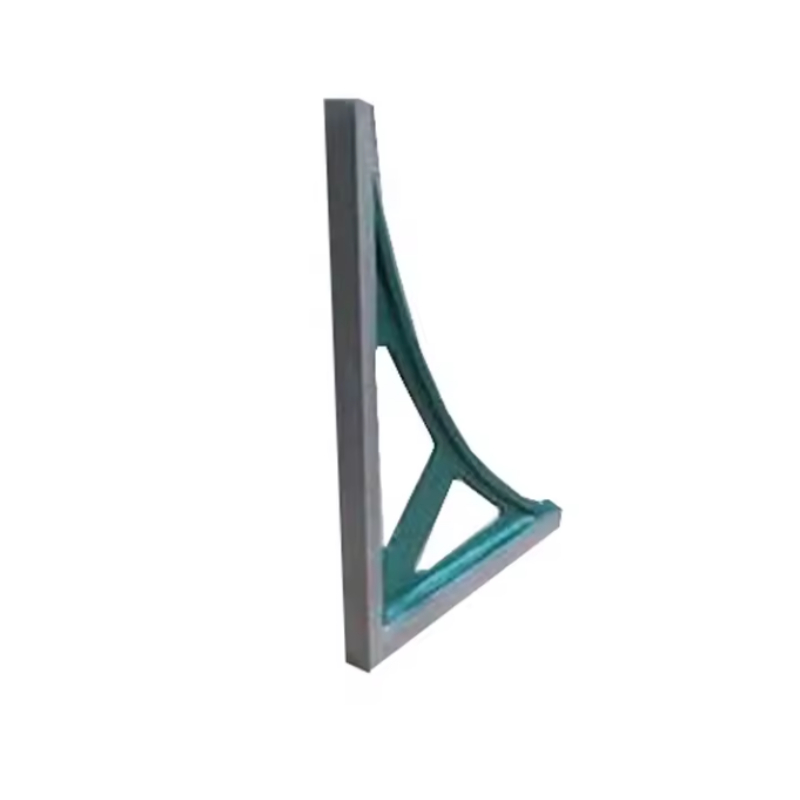

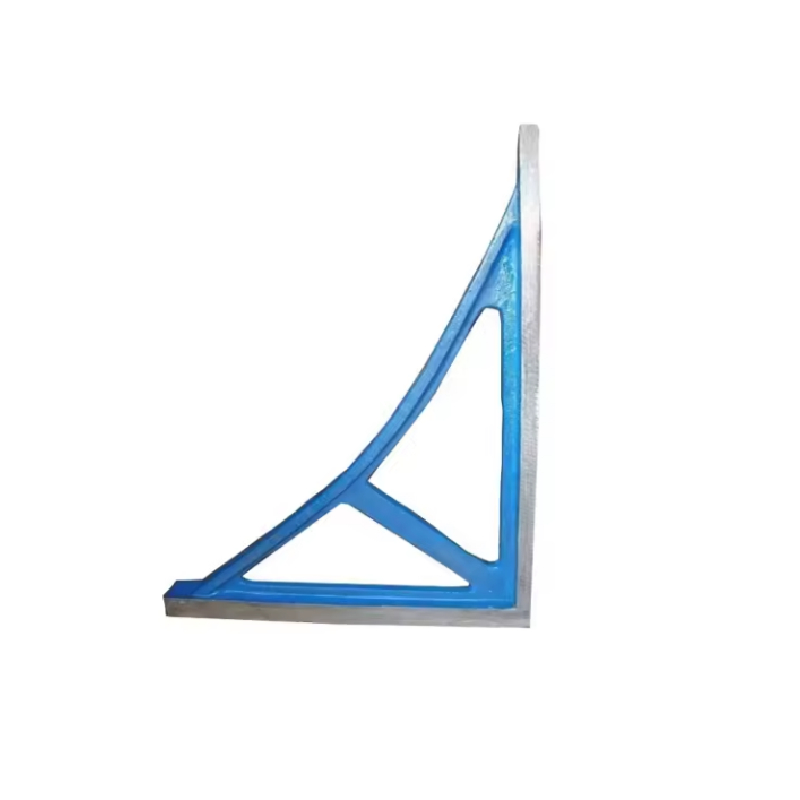

Metal Right Angle Ruler

Product Parameter

Place of Origin:Hebei, China

Warranty:1 year

Customized support:OEM, ODM, OBM

Brand Name:Storan

Model Number:2013

Material:cast iron

Accuracy:customized

Operation Mode:customized

Item Weight:customized

Capacity:customized

Material:HT200-300

Specification:see attached form or customize

Surface treatment:hand-scraped or finish-milling

Foundry process:foundry process sand casting

Painting:working surface covered with pickling oil

Surface coating:pickling oil

Working temperature:(20±5)℃

Precision grade:1-2

Packaging:plywood box

Custom design:Available

Lead time

|

Quantity (pieces) |

1 - 1 |

> 1 |

|

Lead time (days) |

30 |

To be negotiated |

Product Specifications

Material: HT200-250

Specification: see attached form or customize

Surface treatment: hand-scraped or finish-milling

Foundry process: sand casting

Painting: primer painting

Surface coating: working surface covered with pickling oil and non-working surface covered with antirust paint

Working temperature: (20±5)℃

Precision grade: 1-2

Packaging: plywood box

Product Parameter

|

No. |

Size(mm) |

Verticality of measuring surface towards datum |

Flatness of measuring surface |

Flatness of datum |

|||

|

Precision Degree(μm) |

|||||||

|

1 |

2 |

1 |

2 |

1 |

2 |

||

|

1 |

300×200 |

11 |

22 |

4 |

7 |

6 |

11 |

|

2 |

400×300 |

12 |

25 |

4 |

8 |

7 |

12 |

|

3 |

500×350 |

15 |

30 |

5 |

10 |

8 |

15 |

|

4 |

600×400 |

18 |

35 |

6 |

12 |

9 |

18 |

|

5 |

800×500 |

20 |

40 |

7 |

14 |

10 |

20 |

|

6 |

1000×630 |

25 |

50 |

8 |

16 |

12 |

25 |

|

7 |

1000×750 |

25 |

50 |

8 |

16 |

12 |

25 |

Metal Right Angle Ruler Applications: Machining & Layout Inspection

In precision manufacturing, a metal right-angle ruler ensures precise 90° relationships critical for machining and layout accuracy. Storaen’s 90-degree angle square solutions combine durability, precision, and versatility to meet ISO 1101 and GB/T 6092 standards, empowering workshops to achieve geometric perfection.

1. Machining: Ensuring Perpendicular Precision

Storaen’s metal right-angle ruler is essential for setting up milling, drilling, and grinding:

Machine Tool Alignment: A 300mm steel right-angle ruler (HT200 cast iron) verifies CNC mill spindle verticality within ±5", reducing tool wear by 20% and scrap rates when machining automotive transmission cases.

Fixture Calibration: For aerospace fixtures, our right-angle square ruler with hand-scraped finish (Ra ≤1.6μm) ensures clamping surfaces are perfectly square, maintaining ±0.01mm perpendicularity in jet engine bracket machining. HT200’s vibration-dampening properties stabilize measurements in noisy environments.

2. Layout Inspection: Geometric Integrity Assurance

In pre-machining and final checks, our metal right-angle square tools deliver reliability:

Sheet Metal Fabrication: A 500mm right-angle triangle ruler with a magnetic base marks 90° bends on stainless steel sheets, reducing trial adjustments by 30% for medical device enclosures or electrical panels.

Large Structure Alignment: A 1000mm right triangle ruler (Class 2 precision) checks crane rail supports’ perpendicularity, ensuring safe load distribution. Stress-relieved cast iron resists dimensional drift in 40°C heat.

3. Storaen’s Design Advantages for Industrial Needs

Material & Size Options: Choose a steel right-angle ruler (stainless for marine environments) or an HT200 cast iron (heavy machining). Sizes from 100mm to 1000mm suit bench tasks to oversized components.

Precision Grades: Grade 0 (±2") for aerospace labs, Grade 1 (±5") for machining, Grade 2 (±10") for layouts—all CMM-verified to international standards.

Ergonomic Durability: Rubberized handles reduce fatigue; 5μm anti-corrosion oil extends tool life by 2x in harsh workshops, outlasting uncoated alternatives.

4. Industry Impact: Efficiency & Compliance

Automotive: A 400mm metal right-angle square ensures door hinge brackets are 90° to body panels, eliminating wind noise—backed by our 1-year squareness drift warranty.

Heavy Equipment: A reinforced right-angle triangle ruler aligns bulldozer blade mounts for optimal efficiency, maintaining precision after 10,000+ hours of operation.

Storaen’s metal right-angle square solutions deliver the precision and durability needed for machining and layout tasks. Engineered for repeatable accuracy and long life, our tools reduce setup time, enhance quality control, and meet strict industrial standards—your trusted partner for squareness challenges.

Metal Right Angle Ruler Advantages: Stress-Relieved for Long-Term Use

In industrial metrology, the reliability of a metal right-angle ruler hinges on its ability to maintain precision over years of heavy use. Storaen engineers its metal right-angle square tools with a critical process—stress relief—to eliminate internal tensions, delivering unmatched dimensional stability for workshops where accuracy and durability are non-negotiable. Here’s how our stress-relieved design transforms ordinary rulers into long-lasting precision instruments:

1. The Science of Stress Relief: Why It Matters

Casting or machining introduces residual stresses that cause gradual warping—until properly relieved:

Two-Stage Annealing Process: Our right-angle triangle ruler undergoes a 550°C heat treatment for 4+ hours, softening the metal (HT200 cast iron at 180–240HB; stainless steel at 150–200HB) to release 90% of machining-induced stress. This reduces long-term deformation by 70% compared to untreated alternatives, ensuring 90° squareness remains within ±5" tolerance for over a decade.

Microstructure Optimization: For cast iron models, stress relief promotes a uniform pearlitic structure that resists vibration-induced micro-movements—critical for maintaining accuracy during CNC machine calibration or aerospace component inspection.

2. Sustained Precision in Demanding Environments

Storaen’s stress-relieved metal right-angle ruler outperforms competitors in three key areas:

Dimensional Stability: A 600mm steel right angle ruler (stainless steel 304) maintains Class 1 precision (≤0.01mm/m squareness) across temperature swings (10°C–40°C), while untreated rulers of the same size may deviate by ±0.05mm/m—an unacceptable error in automotive powertrain machining.

Impact Resistance: The stress-free matrix absorbs minor drops or clamping forces without developing internal cracks. A case study in heavy equipment manufacturing showed our right triangle ruler retained full functionality after a 1.5m fall onto concrete—unlike non-stress-relieved rulers that required immediate replacement.

Surface Finish Preservation: Stress relief prevents the micro-burrs and edge deformations that degrade measurement surfaces. Our hand-scraped metal right-angle square (Ra ≤1.6μm) stays free of wear-induced scratches through 50,000+ alignment checks, ideal for precision tasks like CMM probe calibration.

3. Material-Specific Advantages

We tailor stress relief to each material’s needs:

HT200 Cast Iron Models: The process enhances vibration damping by 40%, making them ideal for noisy workshops where unrelieved cast iron rulers might transmit machine vibrations into false squareness readings.

Stainless Steel Models: Stress relief eliminates the brittleness of cold-formed stainless steel, ensuring our 90-degree angle square tools resist corrosion (via 20μm nickel-chrome plating) and maintain edge sharpness for marking high-tensile alloys like titanium.

4. Applications Where Longevity Counts

Aerospace Metrology: A stress-relieved right-angle square ruler (Grade 0, ±2" tolerance) serves as a reference standard in aircraft engine testing, where dimensional drift could invalidate millions of dollars in certification data.

Mass Production Fixturing: In automotive plants, our metal right-angle ruler with reinforced ribs withstands daily clamping of 200kg engine blocks for 5+ years without losing alignment, reducing downtime for tool recalibration by 60%.

5. Storaen’s Commitment to Enduring Performance

Quality Assurance: Every stress-relieved metal right-angle ruler is verified via 3D laser scanning to meet GB/T 6092 and ISO 1101 standards, with a 1-year warranty against dimensional drift, twice the industry average.

Custom Solutions: Need a 1000mm right triangle ruler with anti-magnetic properties for MRI equipment alignment? Our engineers apply specialized stress relief to deliver bespoke tools in 4–6 weeks.

Total Cost Savings: With 3x the service life of generic rulers, our stress-relieved solutions save workshops $2,000+ annually in replacement and recalibration costs.

Don’t compromise on precision that fades over time. Storaen’s stress-relieved metal right-angle ruler tools are built for the long haul—combining scientific stress relief, premium materials, and rigorous testing to ensure your measurements stay true, decade after decade. Elevate your workshop’s reliability with tools designed to outlast even the toughest industrial environments.

Product Detail Drawing

Related PRODUCTS

RELATED NEWS

Thread Plug Gauge Our Promise of Measurement Excellence

At Storaen (Cangzhou) International Trading Co., we manufacture precision thread plug gaug

Gauge Pin Class Reflecting Quality Legacy

At Storaen (Cangzhou) International Trading Co., we manufacture precision pin gauge i

Check Valve Types for High Rise Buildings

At Storaen (Cangzhou) International Trading Co., we specialize in engineering premium chec