product advantages

-

Material Properties And Cost Advantages

Good strength and toughness

Cast steel is a material with high strength, and its yield strength and tensile strength can meet the requirements of most industrial pipeline systems. For example, in some high-pressure steam pipelines, cast steel gate valves can withstand pressures of up to tens of MPa without breaking. This strength allows the valve to maintain structural integrity under harsh working conditions, such as frequent occurrences of water hammer in pipelines (pressure shocks caused by sudden changes in fluid velocity).

At the same time, cast steel also has a certain toughness, which can absorb energy when impacted by external forces and avoid sudden brittle fracture. This is a very important safety guarantee for valves installed in environments that may be subject to accidental impacts, such as pipeline systems near construction sites or areas where industrial equipment frequently moves.Cost-effectiveness

Compared with some high-grade alloy steels or special metal materials, the raw material cost of cast steel is relatively low. This gives cast steel gate valves a clear price advantage in large-scale industrial applications and cost-sensitive engineering projects. For example, in municipal water supply systems, a large number of valves are required to control water flow. The use of cast steel gate valves can effectively reduce the material cost of the entire project while ensuring basic performance.

-

Manufacturing Process Flexibility

Manufacturing capability of complex shapes

The casting process of cast steel can produce valve components of various complex shapes. For gate valves, the internal flow channel, gate shape, and valve seat structure can all be designed with complex geometries through precision casting. For example, in order to optimize the flow characteristics of the fluid, the flow channel of the gate valve can be cast into a gradually contracting or expanding shape to reduce the local resistance loss of the fluid. This flexibility of the manufacturing process enables cast steel gate valves to adapt to different fluid media and working requirements.

Wide range of sizes

Cast steel gate valves can be manufactured in various sizes from small to large diameters. Small-diameter cast steel gate valves can be used for fine laboratory piping systems or fluid control of small equipment, while large-diameter cast steel gate valves (such as valves with a diameter of several meters) can be used in large-scale water conservancy projects or chemical raw material transportation pipelines and other occasions, which can meet the needs of different flow rates and pipeline sizes.

-

Repairability And Modifiability

Easy to repair and replace parts

The structure of the cast steel gate valve is relatively simple, and the connection between the various parts is relatively intuitive. When a part of the valve is damaged, such as the gate is worn or the valve seat seal is damaged, these parts can be disassembled and replaced relatively easily. For example, in the daily maintenance of a chemical enterprise, maintenance personnel can remove the damaged gate with simple tools, replace it with a new gate and reinstall it, so that the valve can return to normal working condition and reduce equipment downtime.

Strong modifiability

o If the working conditions of the pipeline system change, such as increased pressure or flow requirements, the cast steel gate valve can adapt to the new working conditions through some modification measures. For example, the valve stem can be reinforced, or a higher strength sealing material can be replaced to meet higher pressure requirements. This modifiability enables the cast steel gate valve to better adapt to the production development and technological upgrading of the enterprise during long-term use.

Product performance

-

Fluid Control Performance

Flow characteristics

o When the cast steel gate valve is fully open, its flow channel is almost straight through, and the fluid resistance coefficient is relatively small. According to experimental data, under the same pipe diameter and flow conditions, the resistance loss of cast steel gate valves is much lower than that of some other types of valves such as stop valves. For example, in water pipelines, the flow coefficient (Cv value) of cast steel gate valves when fully opened can reach a high level, which can achieve efficient transportation of large flows and help improve the transportation efficiency of the entire pipeline system.

Regulation performance

o Although gate valves are generally used in fully open or fully closed states, cast steel gate valves can also play a certain role in some occasions where flow regulation is required. By controlling the opening height of the gate, coarse regulation of fluid flow can be achieved. However, its regulation accuracy is relatively low compared to special regulating valves such as ball valves or regulating valves. In some industrial processes that do not require particularly high flow accuracy, such as simple cooling water flow rate control, cast steel gate valves can meet basic regulation needs.

-

Sealing Performance

Static sealing performance

o The seal between the valve seat and the gate of the cast steel gate valve is the key. In a static state, a good static sealing effect can be achieved through reasonable selection of sealing materials and sealing structure design, such as the use of rubber sealing rings with good elasticity or a combination of metal and non-metal sealing. For example, in a gas transmission pipeline, a cast steel gate valve can effectively prevent gas leakage in a closed state, and its sealing performance can reach a very high level, meeting strict safety standards.

Dynamic sealing performance

o The seal at the valve stem is also crucial. Cast steel gate valves usually use packing seals. By filling with sealing packings such as asbestos and graphite, and matching with appropriate packing gland structures, it can effectively prevent the medium from leaking along the valve stem during the movement of the valve stem. In a high-temperature and high-pressure working environment, the reasonable selection of high-temperature and high-pressure resistant packing materials can ensure the dynamic sealing performance of the valve stem. For example, in the high-temperature oil pipeline of an oil refinery, the valve stem seal of a cast steel gate valve can work stably for a long time.

-

Mechanical Properties

Pressure resistance

o The valve body and main components of a cast steel gate valve can withstand high pressure. Through reasonable structural design and material selection, its pressure resistance level can reach different levels from low pressure (such as PN10) to high pressure (such as PN420). In the pressure test, the cast steel gate valve can maintain structural stability at the specified pressure multiple (such as 1.5 times the working pressure) without visible deformation or leakage. This pressure resistance enables it to be used in pipeline systems of various pressure levels, such as urban gas high-pressure transmission pipelines and industrial steam pipelines.

Temperature resistance

o Cast steel materials themselves have a certain temperature resistance. Generally, cast steel gate valves can work normally in the temperature range of - 29℃ - 425℃. In high temperature environments, the changes in its mechanical properties are relatively small, which can ensure the normal operation of the valve. For example, in the steam pipeline of a thermal power plant, the temperature is as high as hundreds of degrees. The cast steel gate valve can stably control the flow of steam at such a high temperature, and will not cause failures due to softening or reduced strength of the material.

Operational scenarios

-

Energy Industry

Oil and gas extraction and transportation

o At the oil extraction site, cast steel gate valves are used in wellhead devices to control the outflow of crude oil and natural gas. In high-pressure, sandy crude oil pipelines, it can withstand high pressure and a certain degree of abrasion to ensure that crude oil is smoothly transported from the oil well to the refinery. In natural gas pipelines, cast steel gate valves are used as cut-off valves, which can be quickly closed in an emergency to prevent natural gas leakage and ensure transportation safety.

Power generation

o In thermal power plants, cast steel gate valves are widely used in steam pipelines, cooling water pipelines, and fuel pipelines. In steam pipelines, it controls the flow of high-temperature and high-pressure steam to drive the steam turbine to generate electricity; in cooling water pipelines, it adjusts the flow of cooling water to ensure the cooling effect of the generator set; in coal or fuel oil pipelines, it acts as a control valve to achieve precise fuel supply.

-

Chemical Industry

Chemical Raw Materials Transportation and Reaction Process Control

o In the transportation pipeline of chemical raw materials, cast steel gate valves are used to control the flow of various chemical raw materials, such as acids, alkalis, salt solutions and organic chemicals. On the inlet and outlet pipelines of chemical reactors, it can accurately control the inlet and outlet of reaction materials to ensure the smooth progress of chemical reactions. For example, in the fertilizer production process, cast steel gate valves are used to control the transportation and reaction process of raw materials such as ammonia and sulfuric acid.

Chemical Product Storage and Loading and Unloading

o In the storage tank area of chemical products, cast steel gate valves are installed on the inlet and outlet pipelines to control the loading and unloading of products. During the loading and unloading process of liquid chemical products (such as methanol, ethylene glycol, etc.), it can withstand the pressure difference between the tank truck and the storage tank to ensure the safety and accuracy of the loading and unloading process.

-

Water Treatment Industry

Raw Water Transportation and Pretreatment

o In the raw water transportation pipeline of the urban water supply system, cast steel gate valves are used to control the water intake of water sources such as rivers and lakes. In the pretreatment stage of the water treatment plant, such as coagulation, sedimentation, filtration and other process, it controls the flow of water between various treatment units to ensure the quality and efficiency of water treatment.

Sewage treatment and recycling

o In sewage treatment plants, cast steel gate valves are used to control the flow of sewage in various treatment links (such as grilles, aeration tanks, sedimentation tanks, etc.). In sewage recycling systems, it is also used to control the distribution and reuse of recycled water, such as for urban greening irrigation, industrial cooling water replenishment, etc.

-

Buildings And Municipal Engineering

Building water supply and drainage system

o In the water supply and drainage pipelines of buildings, cast steel gate valves are used as the main control valves to control the supply of domestic water, fire water, etc. In the water supply system of high-rise buildings, it can withstand a certain hydrostatic pressure to ensure the stability of water supply. In the fire protection system, cast steel gate valves can be opened or closed quickly to provide sufficient water for fire protection equipment.

Municipal water supply and drainage and heating pipe network

o In the city's water supply and drainage pipe network, cast steel gate valves are used to control sewage discharge and rainwater collection. In the urban heating network, it controls the distribution and circulation of hot water to ensure the heating needs of residents and enterprises. In the urban underground integrated pipeline corridor, cast steel gate valves are important pipeline control equipment, which facilitates the maintenance and management of the pipeline system.

Stainless steel gate valves

-

Excellent Corrosion Resistance

Resistant to corrosion by various chemical media

o Stainless steel gate valves contain alloy elements such as chromium (Cr) and nickel (Ni). Chromium can form a dense chromium oxide protective film on the surface of stainless steel. This film has self-repairing ability and can effectively prevent oxygen, water and other media from contacting the base metal, thereby resisting corrosion. For example, in a seawater environment containing chloride ions (Cl⁻), 316L stainless steel gate valves can well resist pitting and crevice corrosion caused by chloride ions. This is because its high nickel content enhances the material's tolerance to chloride ions. In the chemical industry, stainless steel gate valves can be used to handle various acid, alkali, and salt solutions. For example, in pipelines for conveying highly corrosive media such as nitric acid and sodium hydroxide, they can maintain good performance for a long time.

Anti-environmental corrosion

o Stainless steel gate valves show good corrosion resistance in different natural and industrial environments. In humid marine environments, it will not rust as quickly as ordinary carbon steel valves; in industrial environments polluted by acidic gases such as sulfur dioxide (SO₂), it can also maintain the smoothness of the surface and the integrity of the structure. This ability to resist environmental corrosion makes stainless steel gate valves widely used in outdoor piping systems and pipeline layouts in industrial plants.

-

Hygiene And Cleaning Advantages

Smooth surface and easy to clean

o The surface finish of stainless steel gate valves is high, and its surface roughness can usually reach a low value. This makes it difficult for the medium to retain dirt and impurities when flowing inside the valve. And in occasions where cleaning is required, such as the food and beverage processing industry, its smooth surface can be easily cleaned. For example, in a milk processing production line, stainless steel gate valves can quickly remove residual milk components during the cleaning process between production batches to avoid bacterial growth and cross contamination.

Comply with hygiene standards

o Due to the chemical stability and non-toxicity of stainless steel itself, stainless steel gate valves meet the strict hygiene standards of industries such as food and medicine. In drug production, it will not release harmful metal ions or other impurities into the drugs, ensuring the purity and quality of the drugs. In the fluid control of medical devices, such as valves in hospital disinfection equipment and infusion equipment, the hygienic performance of stainless steel gate valves is an important factor in ensuring medical safety.

-

Appearance And Durability

Beautiful appearance design

o Stainless steel materials have a natural metallic luster. After surface treatment such as polishing, the appearance of stainless steel gate valves is beautiful and generous. In some occasions with high requirements for the appearance of equipment, such as modern food processing plants, water supply and drainage systems of high-end hotels, stainless steel gate valves can enhance the beauty of the entire pipeline system and coordinate with the surrounding environment.

Long-term durability

o The durability of stainless steel gate valves is not only reflected in their corrosion resistance, but also in their structural stability during long-term use. Under normal working conditions, stainless steel gate valves can be used for many years without obvious performance degradation. For example, in the water supply and drainage system of a building, stainless steel gate valves can work reliably within the service life of the building for decades after installation, reducing the trouble and cost of frequent valve replacement.

Product Performance

-

Fluid Control Performance

Accurate Flow Regulation

o Stainless steel gate valves can provide relatively accurate control in some occasions where flow regulation is required. The linear movement of its gate plate can achieve relatively fine regulation of the flow. Compared with cast steel gate valves, stainless steel gate valves can better meet the needs in some occasions where flow accuracy is required, such as the batching process of fine chemicals or the fluid experimental device in the laboratory. For example, in the process of drug formulation in pharmaceutical companies, a certain amount of drug solution can be accurately delivered by accurately controlling the opening degree of the stainless steel gate valve.

Efficient fluid transmission

o In the fully open state, the flow channel of the stainless steel gate valve is unobstructed and the fluid resistance is small. Its flow coefficient (Cv value) is equivalent to that of the cast steel gate valve and even better in some cases. In the liquid delivery pipelines in the food and beverage industry, such as the canning production line of beverages, stainless steel gate valves can efficiently deliver liquids, ensure the rapid operation of the production line, and reduce the energy loss of the liquid at the valve.

-

Sealing Performance

High-level sealing reliability

o The sealing surface of the stainless steel gate valve usually adopts advanced sealing technology and materials. For example, high-performance sealing materials such as polytetrafluoroethylene (PTFE) or reinforced rubber are used. These materials have good elasticity and corrosion resistance and can ensure the sealing effect under different temperature and pressure conditions. In the pipeline system of high-temperature food cooking equipment, the seal of the stainless steel gate valve can prevent steam leakage and ensure the safety and normal operation of the equipment.

Long-term stable sealing life

o Due to the stability of stainless steel materials and the durability of sealing materials, the sealing performance of stainless steel gate valves can remain stable during long-term use. In the aseptic pipeline system of the pharmaceutical industry, its sealing performance can ensure that after multiple opening and closing operations, it still prevents the entry of microorganisms and impurities, prolongs the sealing life of the valve, and reduces the frequency of maintenance and replacement of seals.

Contact Us

Storaen (Cangzhou) International Trading Co.stands tall as a beacon of excellence in the manufacturing realm, nestled in the industrious city of Botou, China. Renowned for its mastery in crafting a versatile array of industrial products, this esteemed company has garnered a sterling reputation for its unwavering commitment to quality and precision engineering.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion Control2024-03-12Why Metric Trapezoidal Thread is Ideal for Precision Motion Control

Why Metric Trapezoidal Thread is Ideal for Precision Motion Control2024-03-12Why Metric Trapezoidal Thread is Ideal for Precision Motion Control -

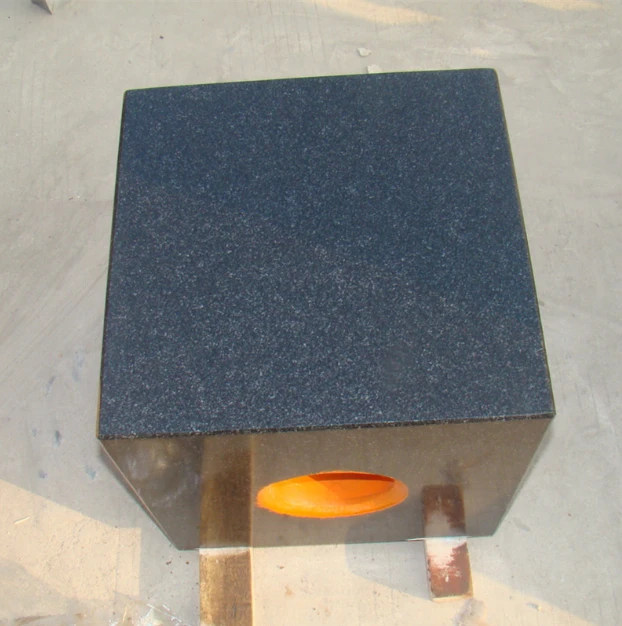

The Unique Properties of a Block of Granite for Industrial Use2024-03-12The Unique Properties of a Block of Granite for Industrial Use

The Unique Properties of a Block of Granite for Industrial Use2024-03-12The Unique Properties of a Block of Granite for Industrial Use -

The Role of Flanged Y Strainers in Preventing Pipeline Clogs2024-03-12The Role of Flanged Y Strainers in Preventing Pipeline Clogs

The Role of Flanged Y Strainers in Preventing Pipeline Clogs2024-03-12The Role of Flanged Y Strainers in Preventing Pipeline Clogs