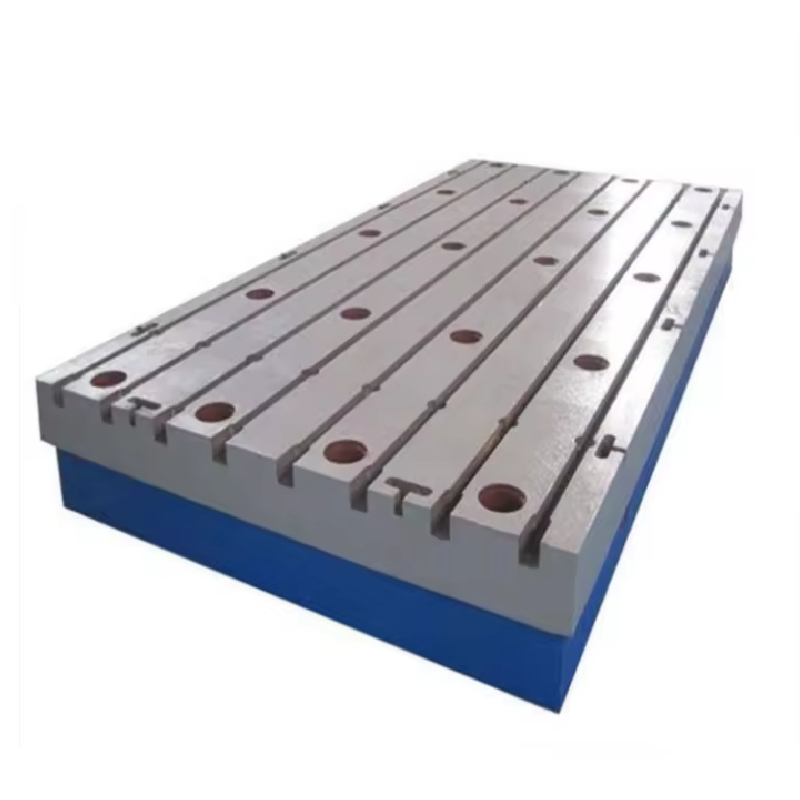

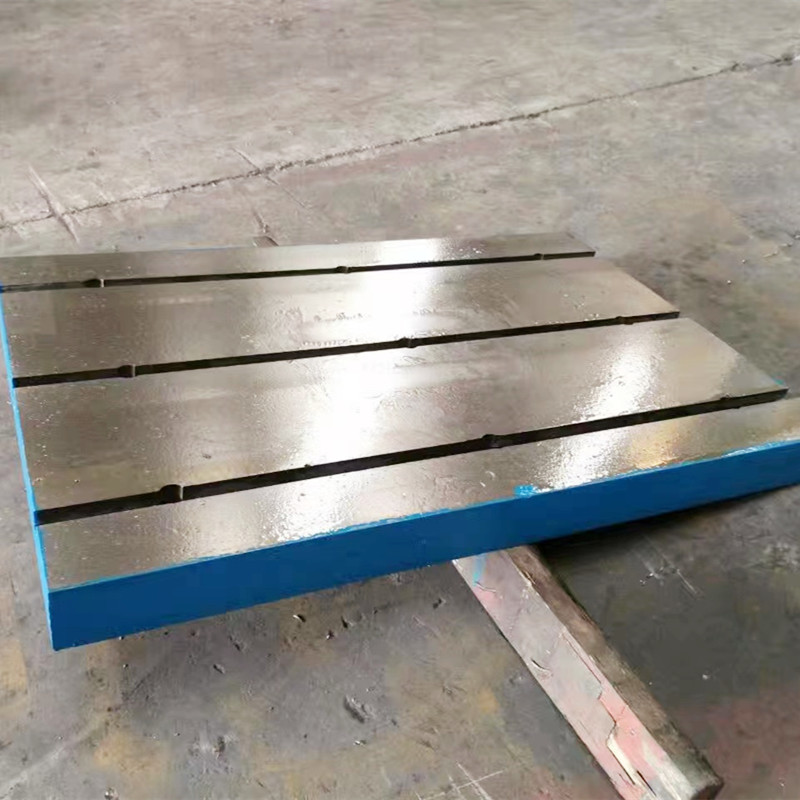

Cast Iron Inspection Surface Plate

Product Parameter

Place of Origin:Hebei, China

Warranty:1 years

Customized support:OEM, ODM, OBM

Brand Name:Storan

Model Number:2011

Material:cast iron

Accuracy:customized

Operation Mode:customized

Item Weight:customized

Capacity:customized

Product name:Cast Iron Surface Plate

Material:HT200-300, QT or steel

Size:200x200-4000x8000mm or customize

Hardness of Working Surface:HB160-240

Foundry process:resin sand casting

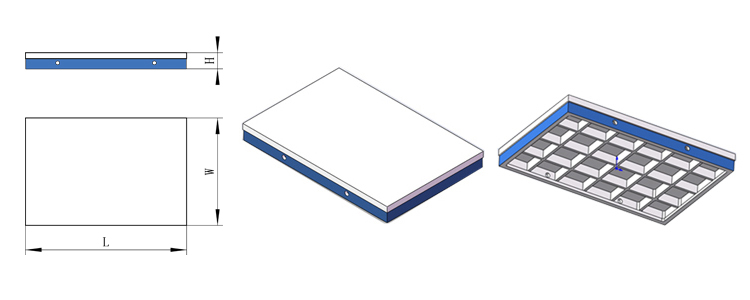

Structure:rib (bone) structure with enough wall thickness

Painting:primer and face paint

Precision grade:0-3

Working temperature:(20±5) ℃

Packaging:plywood box

Lead time

|

Quantity (pieces) |

1 - 100 |

> 100 |

|

Lead time (days) |

30 |

To be negotiated |

Heavy Duty Steel Stand:

Heavy Duty Steel Stand are usually custom-designed to maintain the precision tolerances. Leveling screws and heavy-duty casters are available on the stands. Orders should specify the exact working height: from floor to the top of the surface plate.

Why Choose Storan Cast Iron Surface Plate for Sale?

When it comes to precision measurement and machining, the importance of having a reliable surface plate cannot be overstated. Among the various options available in the market, Storan cast iron surface plates stand out for their superior quality and performance. Here, we will explore the key reasons to consider Storan cast iron surface plates for your needs, as well as the competitive cast iron surface plate price.

First and foremost, Storan cast iron surface plates are recognized for their exceptional stability. Made from high-quality cast iron, these plates offer unparalleled resistance to warping and wear, ensuring consistent accuracy even in the most demanding environments. The durability of Storan plates means they can withstand heavy usage over time without sacrificing precision, making them a smart long-term investment for any workshop or manufacturing setting.

Another significant factor to consider is the precision finish of Storan cast iron surface plates. Each plate is meticulously machined to achieve a flatness that meets stringent industry standards. This level of precision is essential for applications where exact measurements are critical, allowing users to perform their work with confidence.

When discussing the cast iron surface plate price, Storan offers competitive rates that align with the quality and performance of their products. Investing in a Storan cast iron surface plate may result in initial costs, but the long-term benefits in terms of durability and precision certainly outweigh those upfront expenses. Moreover, Storan provides various sizes and models to cater to different requirements, allowing businesses to find the perfect match for their specific needs without compromising on budget.

In conclusion, choosing a Storan cast iron surface plate for sale is a wise decision for anyone seeking reliability, precision, and value. With the right balance of quality and competitive cast iron surface plate price, Storan ensures that your measuring and machining tasks are executed flawlessly. Ensure your operations never falter by making the prudent choice of investing in Storan.

Surface Plates: Granite vs Cast Iron

Cast Iron Surface Plates

Cast iron surface plates have been used for decades in various industrial settings. One of the main advantages of a cast iron surface plate is its durability. Cast iron is known for its ability to withstand heavy loads without deforming, making it an ideal choice for machining and fabrication work. Moreover, its natural damping properties help absorb vibrations, which can enhance measurement accuracy.

However, cast iron surface plates come with their own set of limitations. While they are generally less expensive than granite surface plates, they are also prone to rust and corrosion if not maintained properly. This factor can limit their lifespan and necessitate frequent upkeep. Furthermore, cast iron plates require regular scraping to maintain their flatness, which can be time-consuming and may require the expertise of skilled personnel.

Granite Surface Plates

Granite surface plates are becoming increasingly popular in modern manufacturing and inspection applications due to their numerous benefits. One of the primary advantages of a granite surface plate is its inherent resistance to environmental factors such as moisture and temperature changes. Unlike cast iron, granite does not rust or corrode, making it an excellent choice for long-term use.

Granite surface plates also boast superior flatness and stability compared to their cast iron counterparts. The manufacturing process for granite plates allows for high precision and accuracy, which is crucial for critical measuring tasks. Additionally, granite has an exceptional hardness level, which contributes to its longevity and minimal wear over time.

On the downside, granite surface plates can be more expensive than cast iron options. They are also more brittle, which means they can chip or crack if subjected to extreme impact or stress. Therefore, careful handling is necessary to ensure the longevity of granite plates.

In the debate between cast iron surface plates and granite surface plates, the choice largely depends on your specific applications, budget, and maintenance preferences. If you require a robust plate that can withstand heavy loads and do not mind the extra maintenance involved, a cast iron surface plate may be the right choice for you. On the other hand, if you seek superior accuracy, reduced maintenance, and excellent longevity, a granite surface plate would be the more suitable option.

From 200x200 to 4000x8000mm: How Our Cast Iron Surface Plates Adapt to Industry-Wide Inspection Needs

STORAEN’s cast iron surface plates redefine versatility in industrial metrology, offering an unmatched size range—from compact 200x200mm benches to massive 4000x8000mm platforms—that seamlessly adapts to inspection, marking, and calibration needs across manufacturing, fabrication, and engineering sectors. Crafted from premium HT200-300 cast iron (HB160-240 hardness) with stress-relieved construction, our cast iron base plates and metal fabrication tables combine precision, rigidity, and customizable features to serve as the backbone of quality control in applications ranging from micro-precision to heavy-duty industrial tasks.

Tailored Sizing for Every Scale of Operation

Micro-Precision & Bench-Top Use (200x200–1000x1000mm)

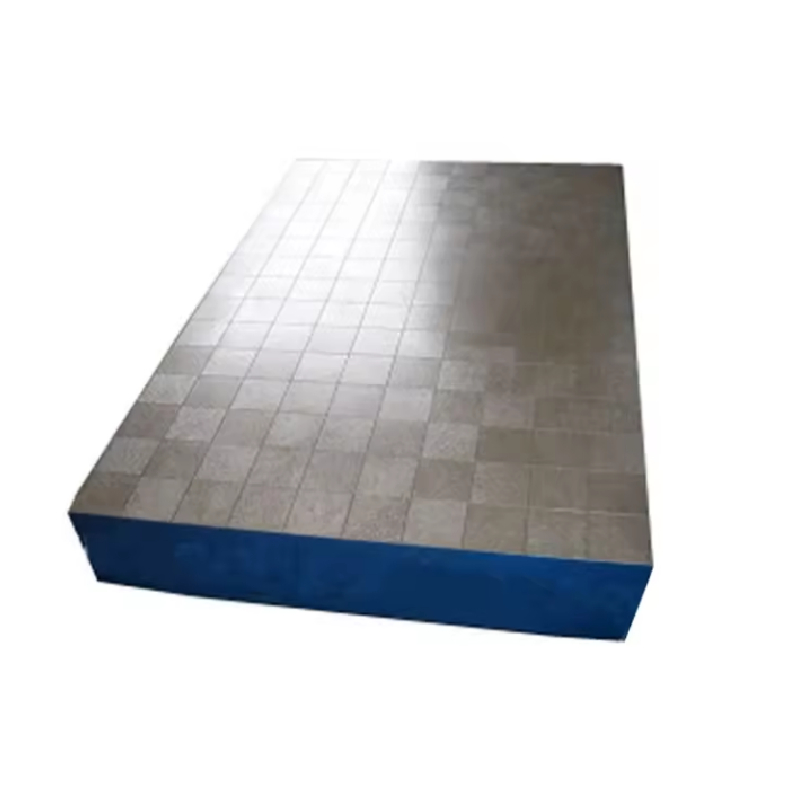

Ideal for electronics, watchmaking, and medical device manufacturing, these compact cast iron surface plates provide a stable standard for inspecting small components like connectors or gearboxes. Their fine-ground surface (Ra1.6–3.2μm) and 0–1 class precision (flatness ≤0.02mm/1000mm) ensure micron-level accuracy, while lightweight design (15–50kg) enables easy integration into lab benches or CNC machine nearby insepction.

General Engineering & Modular Setups (1000x1500–2000x3000mm)

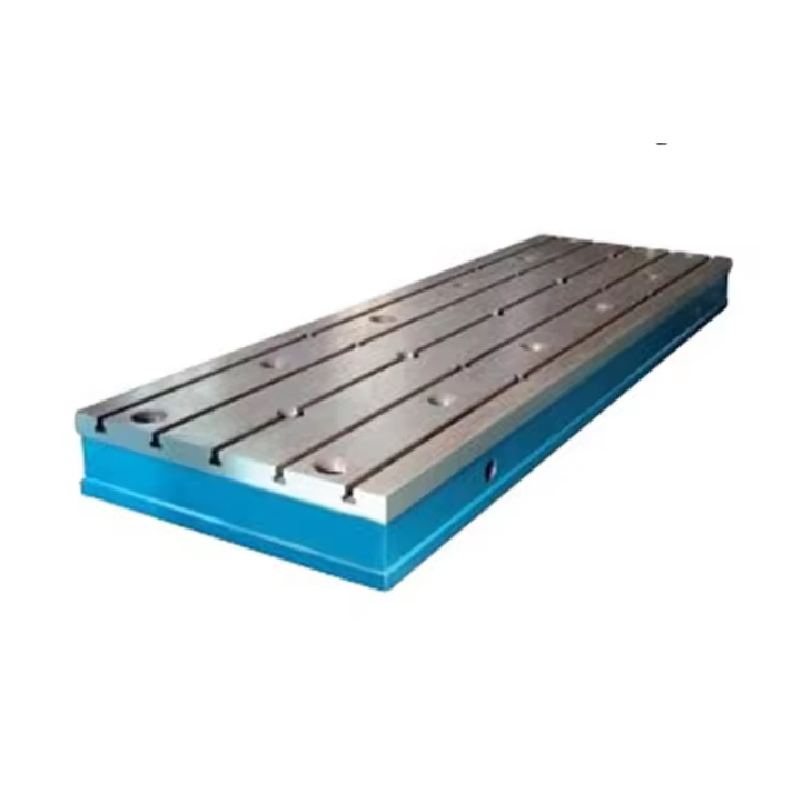

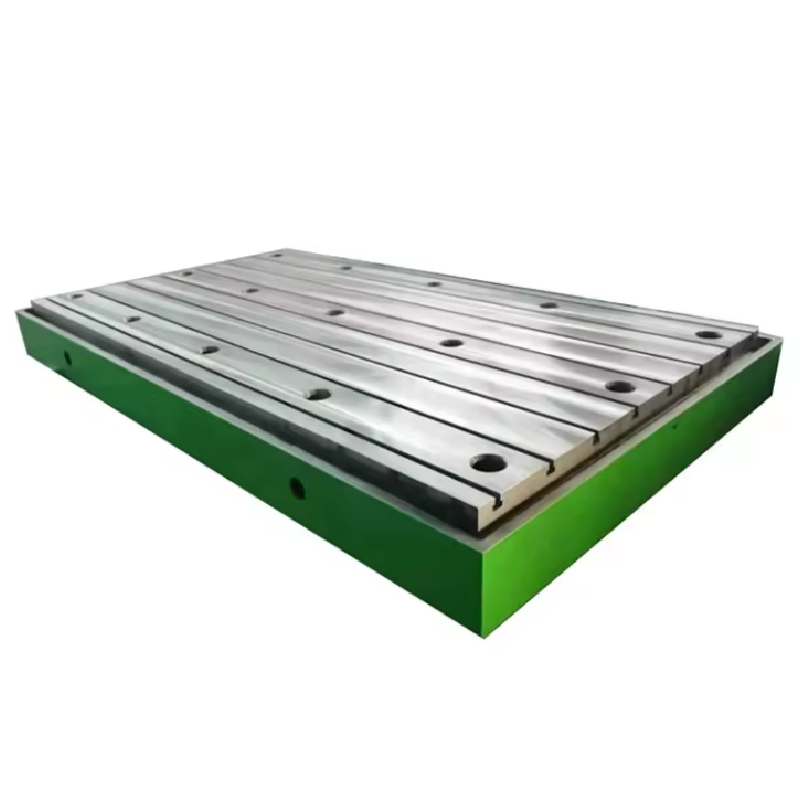

The workhorse of mechanical workshops, these mid-range plates excel in verifying medium-sized parts—from automotive engine blocks to hydraulic valves. Reinforced with ribbed undersides, they withstand static loads up to 2000kg/m², making them perfect as steel fabrication tables for welding fixture alignment or CNC machine calibration. Optional T-slots (ISO 2571 standard) and threaded holes (M8–M24) enhance adaptability, allowing quick clamping of gauges, fixtures, or laser alignment tools.

Heavy-Duty Industrial & Oversized Projects (2500x4000–4000x8000mm)

For aerospace structural components, heavy machinery frames, or shipbuilding parts, our largest cast iron base plates deliver uncompromising rigidity. Their thickened edges (50–80mm) and dense HT300 material resist deformation under 3000kg+ loads, while stress-relief annealing (heated to 550°C for 4 hours) eliminates internal tensions, ensuring flatness stability even in high-temperature workshops. These plates often serve as permanent installation bases for coordinate measuring machines (CMMs) or robotic welding cells, providing a reliable reference for mill-scale inspections.

Customization for Unique Application Demands

Beyond standard sizes, we offer tailored solutions to meet specific needs:

Surface Treatments: Choose from anti-rust paint (ideal for humid environments), epoxy coatings (chemical resistance), or super-finished surfaces (Ra0.8μm for metrology labs).

Structural Enhancements: Add reinforced corner brackets for forklift handling, recessed mounting zones for automated equipment, or beveled edges for safe operator access in tight workspaces.

Multi-Platform Integration: Bolt together multiple metal fabrication tables using precision alignment pins, creating seamless extended surfaces for oversized assemblies—common in agricultural machinery or oil rig component production.

Your Go-To Solution for Any Inspection Scale

Whether you need a compact cast iron surface plate for prototyping, a mid-sized steel fabrication table for batch production, or an industrial-grade cast iron base plate for megaprojects, STORAEN’s size range and customization options ensure the perfect fit. By combining the timeless reliability of cast iron with engineering flexibility, we empower manufacturers to tackle every inspection challenge—from the tiniest component to the largest structure—with confidence in their measurement standard. Explore our full range today and discover why precision has no size limit.

Solving Mechanical Inspection Pain Points: How Cast Iron Surface Plates Eliminate Workpiece Errors

In mechanical machining, inconsistent measurements, time-consuming setups, and unreliable reference surfaces plague quality control—until STORAEN’s cast iron surface plates enter the picture. Engineered to transform inspection workflows, our cast iron base plates and metal fabrication tables address core pain points with unmatched precision, rigidity, and adaptability, ensuring every workpiece defect is detected with confidence.

Pain Point 1: Inaccurate Positioning Leading to Rework

Many shops struggle with unstable measurement bases that cause misaligned gauges and false pass/fail results. STORAEN’s cast iron surface plates (HT200-300 material, HB160-240 hardness) provide a rock-solid foundation:

Stress-Relieved Stability: Annealed at 550°C for 4 hours, internal casting stresses are eliminated, preventing warping that could skew readings—critical for precision tasks like CNC machine calibration or gearbox flatness checks.

Micron-Level Flatness: With precision grades ranging from 0 (0.02mm/1000mm flatness) to 3 (0.1mm/1000mm), these plates offer a true planar reference that makes deviations as small as 20 microns (0.02mm) visible, ensuring no defect goes undetected.

Pain Point 2: Inefficient Setups for Diverse Workpieces

Switching between small connectors and large machine frames shouldn’t require multiple tables. Our steel fabrication tables solve this with:

Modular Versatility: A grid of optional T-slots (ISO 2571) and threaded holes (M8–M24) allows quick clamping of angle plates, height gauges, or magnetic fixtures, reducing setup time by 50% compared to unstructured surfaces.

Size for Every Scale: From 200x200mm benches for micro-components to 4000x8000mm platforms for heavy machinery, each plate’s ribbed understructure supports 15kg to 3000kg loads without deflection, eliminating the need for makeshift supports that compromise accuracy.

Pain Point 3: High Maintenance and Short Lifespan

Traditional measurement surfaces degrade over time due to wear or corrosion, but our cast iron base plates deliver lasting performance:

Durability by Design: The dense grain structure of HT200 cast iron resists scratches and indentations from frequent gauge contact, while optional anti-rust paint or epoxy coatings protect against coolant spills and humid environments—extending service life by 20% compared to uncoated alternatives.

Low-Cost Upkeep: Unlike granite plates that crack under impact or require delicate handling, our cast iron surfaces can be re-ground to restore precision, offering a cost-effective solution for high-traffic workshops.

Why STORAEN Cast Iron Surface Plates Excel

Compliance Without Compromise: Certified to ISO 9001 and JB/T7974-99, each plate includes a traceable calibration report, ensuring acceptability in automotive, aerospace, and heavy equipment quality audits.

Custom Solutions for Unique Needs: Need a plate with recessed mounting zones for robotic arms or beveled edges for operator safety? Our team tailors dimensions, surface finishes (Ra1.6–3.2μm), and structural features to fit your workflow—no workaround required.

Turn Inspection Headaches into Confident Quality Control

Whether you’re verifying the flatness of a hydraulic manifold, marking drill points on a steel frame, or calibrating a CMM, STORAEN’s cast iron surface plates eliminate the guesswork. By providing a stable, accurate, and durable reference surface, they transform the most frustrating inspection challenges into streamlined, reliable processes—so you can focus on what matters: delivering defect-free products, every time.

Upgrade your quality control with a cast iron base plate or metal fabrication table built to outperform. Explore our range today and see how precision engineering solves even the toughest machining pain points.

Product Specifications

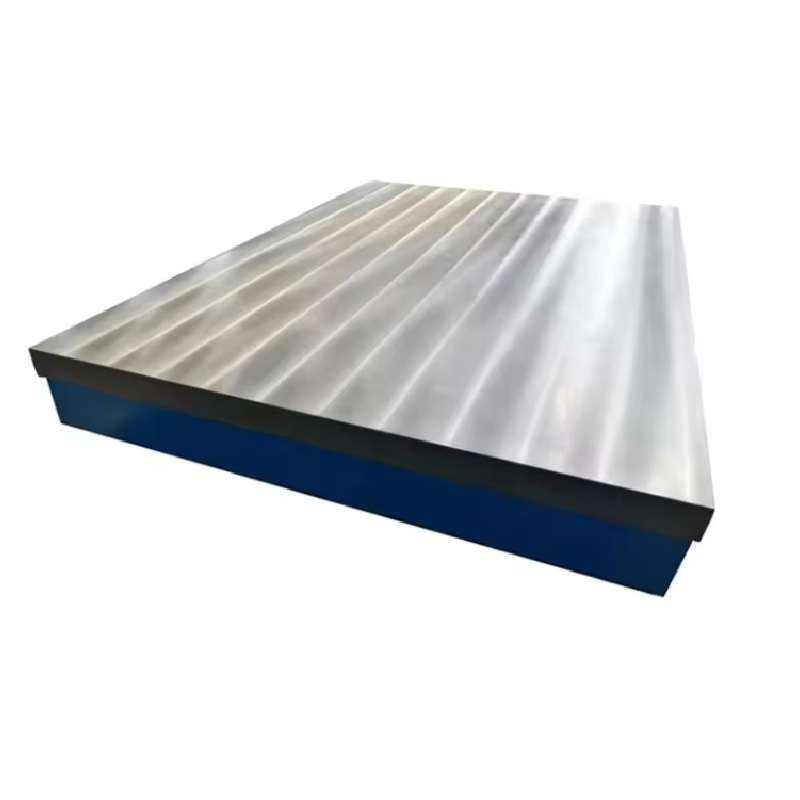

Material: HT200-300 Specification: 200x200-4000x8000mm or customized Working Surface: flat, grid slots for location, tapped holes, T-slots Hardness of the working surface: HB160-240 Surface treatment: precisely finished by planning and hand scraping Foundry process: resin sand casting Structure: rib (bone) structure with enough wall thickness Painting: primer and face paint Surface coating: working surface covered with pickling oil and non-working surface covered with antirust paint Heat-treated: available, for stress relief Stands: available for corresponding sizes Precision grade: 0-3 Working temperature: (20±5) ℃ Packaging: plywood box

Product Parameter

|

No. |

Width X Length(mm) |

Precision Grade |

|||

|

|

|

0 |

1 |

2 |

3 |

|

|

|

Flatness (μm) |

|||

|

1 |

200X200 |

3.5 |

7 |

14 |

|

|

2 |

300X200 |

4 |

8 |

15 |

|

|

3 |

300X300 |

4 |

8 |

15 |

|

|

4 |

300X400 |

4 |

8 |

16 |

|

|

5 |

400X400 |

4.5 |

8.5 |

17 |

|

|

6 |

400X500 |

4.5 |

9 |

18 |

|

|

7 |

400X600 |

5 |

10 |

19 |

|

|

8 |

500X500 |

5 |

10 |

19 |

|

|

9 |

500X600 |

5 |

10 |

19 |

|

|

10 |

500X800 |

5.5 |

11 |

21 |

|

|

11 |

600X800 |

5.5 |

11 |

22 |

|

|

12 |

600X900 |

6 |

11.5 |

23 |

|

|

13 |

1000X750 |

|

12.5 |

25 |

50 |

|

14 |

1000X1000 |

|

13.5 |

27 |

54 |

|

15 |

1000X1200 |

|

14 |

29 |

58 |

|

16 |

1000X1500 |

|

16 |

32 |

63 |

|

17 |

1000X2000 |

|

18.5 |

37 |

74 |

|

18 |

1500X2000 |

|

20 |

40 |

80 |

|

19 |

1500X2500 |

|

22.5 |

45 |

90 |

|

20 |

1500X3000 |

|

25 |

50 |

100 |

|

21 |

2000X2000 |

|

22 |

44 |

88 |

|

22 |

2000X3000 |

|

27 |

53 |

106 |

|

23 |

2000X4000 |

|

32 |

64 |

127 |

|

24 |

2000X5000 |

|

37 |

75 |

150 |

|

25 |

2000X6000 |

|

43 |

86 |

172 |

|

26 |

2000X7000 |

|

49 |

97 |

194 |

|

27 |

2000X8000 |

|

54.5 |

109 |

218 |

|

28 |

2500X3000 |

|

28.5 |

57 |

114 |

|

29 |

2500X4000 |

|

33 |

67 |

133 |

|

30 |

2500X5000 |

|

39 |

77 |

154 |

|

31 |

2500X6000 |

|

|

88 |

176 |

|

32 |

2500X7000 |

|

|

99 |

198 |

|

33 |

2500X8000 |

|

|

110 |

221 |

|

34 |

3000X3000 |

|

|

61 |

122 |

|

35 |

3000X4000 |

|

|

70 |

140 |

|

36 |

3000X5000 |

|

|

80 |

160 |

|

37 |

3000X6000 |

|

|

90.5 |

181 |

|

38 |

3000X7000 |

|

|

101 |

203 |

|

39 |

3000X8000 |

|

|

112.5 |

225 |

|

40 |

4000X4000 |

|

|

78 |

156 |

|

41 |

4000X5000 |

|

|

87 |

174 |

|

42 |

4000X6000 |

|

|

96.5 |

193 |

|

43 |

4000X7000 |

|

|

107 |

213.5 |

|

44 |

4000X8000 |

|

|

117 |

235 |

Product Detail Drawing

Related PRODUCTS

RELATED NEWS

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal Systems

A flanged gate valve is an essential element in fluid control systems across multiple industries, known for its robust construction and leak-proof connection.

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline Control

In today’s fast-paced industrial and municipal applications, the importance of reliable valve performance cannot be overstated.

Gate Valve Types: Understanding the Options for Your Pipeline Systems

Gate valves are a critical component in various piping systems, used to start or stop the flow of liquid or gas.