Ball Check Valve

Product Description

|

Type: |

Ball Check Valve |

Connection: |

Flange Ends |

|

Temperature: |

0-80℃ |

Pressure: |

PN10/16 |

|

Material: |

Ductile Iron QT450-10 |

Media: |

Water,Gas Oil Etc |

|

Structure: |

Control |

Port Size: |

DN150 |

The rubber ball adopts hollow steel ball with elastic rubber to ensure sealing and reduce the damage to the pipeline system in the process of valve closing. When the valve is opened, the conical body with holes can fix the steel ball and eliminate the pressure on the contact surface between the rubber ball and the conical body, so that the contact is surface contact, and reduce the hydraulic loss caused by the trembling of the rubber ball in the valve.

In large piping system with three port or four port ball check valves can replace a large valve plate structure, reduce weight of valve plate, the passage is free-standing porous structure, sphere put in every hole, in the process of the liquid into the body and out of the way its, mutual interference, reduce impact and vibration in the process of valve, reduce the noise, and eliminate any running fault. Multi-channel spherica

Ductile Iron QT450-10 vs Traditional Materials: Corrosion-Resistant Pressure Technology Breakthrough in Ball Check Valves(H2)

STORAEN’s integration of ductile iron QT450-10 in our ball check valve designs represents a transformative advancement in industrial fluid control, surpassing traditional materials like carbon steel and brass in strength, corrosion resistance, and operational durability. As leading ball check valve manufacturers, we leverage this premium material to engineer valves that excel in the most demanding environments—here’s how it outperforms conventional options.

1. Unmatched Mechanical Robustness

Ductile iron QT450-10 offers a tensile strength of 450MPa—50% higher than standard cast iron and 20% stronger than carbon steel (ASTM A216 WCB). This superior strength allows our ball type check valve to handle working pressures up to 2.5MPa (PN25) while maintaining ductility, resisting cracking even at -10°C. In contrast, carbon steel valves, though strong, are prone to fatigue under pressure fluctuations, while brass lacks the rigidity for high-pressure systems (max 1.6MPa). The result? A 40% longer service life in industrial pipelines subjected to frequent pressure surges.

2. Enhanced Corrosion Resistance for Harsh Media

The compact graphite structure of QT450 ductile iron provides inherent resistance to mild corrosives (pH 6–8), such as industrial water, sewage, and non-oxidizing gases—eliminating the need for frequent protective coatings required by carbon steel. When paired with our EPDM/NBR rubber-sealed balls in ball style check valve designs, it forms a dual-barrier system that reduces maintenance by 30% compared to uncoated steel alternatives. For more aggressive environments, optional epoxy lining further boosts chemical resistance, outperforming brass in high-temperature applications (up to 80°C) while withstanding higher pressures—brass struggles with pressures over 1.6MPa and is unsuitable for particle-laden fluids.

3. Design Versatility for Every Application

STORAEN’s ductile iron ball check valves are available in configurations to suit diverse needs:

Threaded Connections (DN15–DN50): Lightweight and easy to install, ideal for residential plumbing or small-scale industrial setups requiring threaded ball check valves.

Flanged Models (DN65–DN300): Heavy-duty designs compliant with ASME B16.5 and DIN PN16, ensuring seamless integration into commercial and industrial pipelines worldwide.

Universal Installation: The balanced multi-ball design functions reliably in both horizontal and vertical orientations, eliminating the positional restrictions of swing check valves and making it a versatile choice for horizontal ball check valve applications in HVAC systems or water treatment plants.

Choose the Material That Outperforms

Whether you need a durable solution for industrial water mains or a reliable valve for commercial HVAC systems, STORAEN’s ductile iron ball check valves deliver the strength, corrosion resistance, and adaptability that traditional materials cannot match. Say goodbye to frequent replacements and maintenance—our valves are engineered to thrive in challenging conditions, backed by the expertise of a trusted ball check valve manufacturer.

Explore our range of ball valves for sale today and experience the technological breakthrough that’s redefining backflow prevention. Trust in ductile iron’s proven performance—because in fluid control, durability is non-negotiable.

l check valve has no joint parts (shaft and shaft sleeve exist, no relative mechanical friction movement, compared with swing check valve, no wearing parts exist, with a long service life, and no maintenance work.

|

Product Name |

Material |

|

Valve Body |

Ductile iron, plastic spraying |

|

Applicable temperature |

≤100℃ |

|

Connection method |

Flange |

|

material |

Ductile iron |

|

Wedge Nut |

Steel or Brass |

Product Parameter

|

Nominal diameter |

50-300mm |

50-300mm |

50-300mm |

|

Nominal pressure |

1.0mpa |

1.6mpa |

2.5mpa |

|

Shell test |

1.5mpa |

2.4mpa |

3.75mpa |

|

Sealing test |

1.1mpa |

1.76mpa |

2.75mpa |

|

Air seal test |

0.6mpa |

0.6mpa |

0.6mpa |

|

Applicable temperature |

≤100℃ |

≤100℃ |

≤100℃ |

|

Applicable medium |

water |

water |

water |

|

Ball check Valve |

flange thickness (mm) |

flange outer circle (mm) |

waterline height (mm) |

waterline diameter (mm) |

Height (mm) |

Length (mm) |

Weight (KG) |

|

DN50 |

15 |

160 |

1.5 |

100 |

185 |

220 |

7.5 |

|

DN65 |

15 |

180 |

1.5 |

118 |

198 |

222 |

9 |

|

DN80 |

17 |

195 |

2 |

132 |

225 |

258 |

11.5 |

|

DN100 |

18.5 |

215 |

2 |

154 |

255 |

283 |

15.5 |

|

DN125 |

19 |

245 |

2 |

172 |

285 |

319 |

28 |

|

DN150 |

19 |

280 |

2 |

217 |

340 |

354 |

32 |

|

DN200 |

20 |

335 |

2 |

262 |

400 |

432 |

53 |

|

DN250 |

22 |

405 |

2.5 |

307 |

465 |

496 |

83 |

|

DN300 |

25 |

460 |

2.5 |

357 |

515 |

552 |

133 |

Ball Check Valve Function

In the realm of fluid dynamics and industrial applications, the importance of reliable components cannot be overstated. One such crucial component is the ball check valve. This device is engineered to permit the flow of fluid in one direction while effectively preventing reverse flow, ensuring system integrity and operational efficiency.

The fundamental function of a ball check valve is based on a simple yet effective mechanism. It consists of a spherical ball positioned in a casing that has an inlet and an outlet. During normal operation, when fluid flows in the designated direction, the pressure forces the ball away from the seat, allowing unhindered passage. However, if there is any attempt for the fluid to flow in the opposite direction, the ball is forced against the seat, creating a watertight seal. This pivotal action prevents backflow, which can lead to contamination, pressure drops, and potential system failures.

Ball check valves are particularly favored in various applications, ranging from wastewater management to HVAC systems, owing to their durability and low maintenance requirements. Their design minimizes turbulence and pressure loss, making them an efficient choice for both high and low-pressure systems. Additionally, the simple construction of a ball check valve facilitates easy installation and replacement, offering a practical solution for engineers and technicians in diverse industries.

In summary, the ball check valve serves a vital role in maintaining the directional flow of fluids, protecting systems from reverse flow, and ensuring optimal performance. As industries continue to prioritize efficiency and system reliability, understanding the function of ball check valves becomes paramount for professionals engaged in fluid control technologies. Investing in high-quality ball check valves can significantly enhance operational efficacy while safeguarding infrastructure from potential hazards.

In conclusion, whether in residential plumbing or complex industrial systems, the ball check valve is an indispensable component that guarantees the seamless operation of fluid transport systems.

Why Choose Storaen Ball Check Valve Manufacturer

When it comes to ensuring the efficiency and safety of fluid systems, selecting the right ball check valve manufacturer is crucial. Storaen stands out as a leading ball check valve manufacturer, offering not only high-quality products but also a range of benefits that cater to various industrial needs.

One of the primary reasons for choosing Storaen is the unrivaled quality of its ball check valves. With rigorous testing and adherence to industry standards, Storaen ensures that every valve is built to last, minimizing the risk of leaks and failures that can lead to operational downtime. This durability is essential for businesses looking to maintain productivity and efficiency.

In addition to quality, Storaen prides itself on innovation. The company continually invests in research and development to improve the design and functionality of its ball check valves. This commitment to innovation means that customers can rely on Storaen's products to incorporate the latest technologies, providing enhanced performance and reliability in a variety of applications.

Furthermore, Storaen offers excellent customer support. Their experienced team understands the complexities of different industries and can provide tailored solutions to meet specific needs. Whether it’s assisting with technical inquiries or guiding you through the selection process, Storaen’s customer support ensures a seamless experience, making it easier for businesses to implement effective fluid control solutions.

Lastly, competitive ball check valve price is another key factor that makes Storaen a preferred ball check valve manufacturer. By maintaining cost-effective production processes without compromising quality, Storaen positions itself as a valuable partner for businesses seeking to optimize their operational expenditures.

In summary, choosing Storaen as your ball check valve manufacturer guarantees quality, innovation, outstanding customer support, and competitive pricing. For industries that depend on reliable fluid control, Storaen is undoubtedly the best choice.

Multi-Ball Multi-Channel Design: How This Ball Check Valve Achieves 99% Backflow Prevention Efficiency

STORAEN’s ball check valve redefines backflow prevention through an innovative multi-ball, multi-channel design, engineered to deliver unmatched efficiency in fluid control. Unlike traditional check valves, our solution uses multiple rubber-coated balls and a porous cone structure to create a dynamic sealing system, making it the go-to choice for industrial pipelines, water supply networks, and HVAC systems. Here’s how this design revolutionizes backflow prevention.

The Mechanics of Multi-Ball Sealing

At the core of our ball-type check valve is a cluster of precision-molded rubber balls (EPDM/NBR) housed within a perforated cone. When flow is forward, the balls float freely, allowing unobstructed passage through the multi-channels, reducing hydraulic loss by 35% compared to swing check valves. When flow reverses, the balls simultaneously seal against the cone’s seating surface, creating a multi-point barrier that blocks backflow with 99% efficiency. This design eliminates single-point failure risks found in traditional ball-style check valve models.

Engineered for Durability and Performance

Rugged Materials: The valve body (QT450 ductile iron or 316L stainless steel) withstands pressures up to 2.5MPa and temperatures from 0°C to 80°C, ensuring reliability in harsh environments.

Zero Wear Operation: The balls float without contacting metal surfaces, eliminating abrasion and extending service life to 50,000+ cycles—twice that of conventional check valves.

Versatile Connections: Available as threaded ball check valve (DN15–DN50) or flanged (DN65–DN300), compatible with ASME and DIN standards for global installations.

Applications Across Industries

Water Treatment: Prevents backflow in municipal water mains, with the multi-channel design resisting debris buildup in dirty water systems.

HVAC Systems: Reduces noise and vibration in chilled water loops, thanks to the balls’ cushioned closure—ideal for horizontal ball check valve installations in commercial buildings.

Industrial Processes: Handles moderate slurries and particle-laden fluids, as the multi-ball design minimizes clogging risks compared to single-disc valves.

Why Choose STORAEN as Your Ball Check Valve Manufacturer

Custom Solutions: Tailored designs for specific flow rates, pressures, or media—from food-grade brass variants to heavy-duty cast iron for industrial use.

Tested Reliability: Every valve undergoes 1.5x pressure testing (shell) and 1.1x seat testing, ensuring compliance with ISO 9001 and API standards.

Ready Stock: A wide range of ball valves for sale, including common sizes (DN50–DN200), available for immediate shipment to minimize project delays.

Experience Next-Level Backflow Prevention

STORAEN’s multi-ball multi-channel ball check valve combines innovation and durability to protect your systems from backflow damage. Whether you need a standard threaded ball check valve for a small project or a custom flanged solution for industrial scale, our design ensures optimal performance and peace of mind.

As leading ball check valve manufacturers, we’re committed to delivering products that exceed industry standards. Explore our range of ball valves for sale today and discover why engineers trust our multi-ball technology for critical backflow prevention.

Ductile Iron QT450-10 vs Traditional Materials: Corrosion-Resistant Pressure Technology Breakthrough in Ball Check Valves

STORAEN’s integration of ductile iron QT450-10 in our ball check valve designs represents a transformative advancement in industrial fluid control, surpassing traditional materials like carbon steel and brass in strength, corrosion resistance, and operational durability. As leading ball check valve manufacturers, we leverage this premium material to engineer valves that excel in the most demanding environments—here’s how it outperforms conventional options.

1. Unmatched Mechanical Robustness

Ductile iron QT450-10 offers a tensile strength of 450MPa—50% higher than standard cast iron and 20% stronger than carbon steel (ASTM A216 WCB). This superior strength allows our ball-type check valve to handle working pressures up to 2.5MPa (PN25) while maintaining ductility, resisting cracking even at -10°C. In contrast, carbon steel valves, though strong, are prone to fatigue under pressure fluctuations, while brass lacks the rigidity for high-pressure systems (max 1.6MPa). The result? A 40% longer service life in industrial pipelines subjected to frequent pressure surges.

2. Enhanced Corrosion Resistance for Harsh Media

The compact graphite structure of QT450 ductile iron provides inherent resistance to mild corrosives (pH 6–8), such as industrial water, sewage, and non-oxidizing gases, eliminating the need for frequent protective coatings required by carbon steel. When paired with our EPDM/NBR rubber-sealed balls in ball-style check valve designs, it forms a dual-barrier system that reduces maintenance by 30% compared to uncoated steel alternatives. For more aggressive environments, optional epoxy lining further boosts chemical resistance, outperforming brass in high-temperature applications (up to 80°C) while withstanding higher pressures—brass struggles with pressures over 1.6MPa and is unsuitable for particle-laden fluids.

3. Design Versatility for Every Application

STORAEN’s ductile iron ball check valves are available in configurations to suit diverse needs:

Threaded Connections (DN15–DN50): Lightweight and easy to install, ideal for residential plumbing or small-scale industrial setups requiring threaded ball check valves.

Flanged Models (DN65–DN300): Heavy-duty designs compliant with ASME B16.5 and DIN PN16, ensuring seamless integration into commercial and industrial pipelines worldwide.

Universal Installation: The balanced multi-ball design functions reliably in both horizontal and vertical orientations, eliminating the positional restrictions of swing check valves and making it a versatile choice for horizontal ball check valve applications in HVAC systems or water treatment plants.

Choose the Material That Outperforms

Whether you need a durable solution for industrial water mains or a reliable valve for commercial HVAC systems, STORAEN’s ductile iron ball check valves deliver the strength, corrosion resistance, and adaptability that traditional materials cannot match. Say goodbye to frequent replacements and maintenance—our valves are engineered to thrive in challenging conditions, backed by the expertise of a trusted ball check valve manufacturer.

Explore our range of ball valves for sale today and experience the technological breakthrough that’s redefining backflow prevention. Trust in ductile iron’s proven performance, because in fluid control, durability is non-negotiable.

Related PRODUCTS

RELATED NEWS

Thread Micrometer Set Features

Precision measurement in manufacturing requires specialized tools like micrometer set products, particularly when dealing with threaded components.

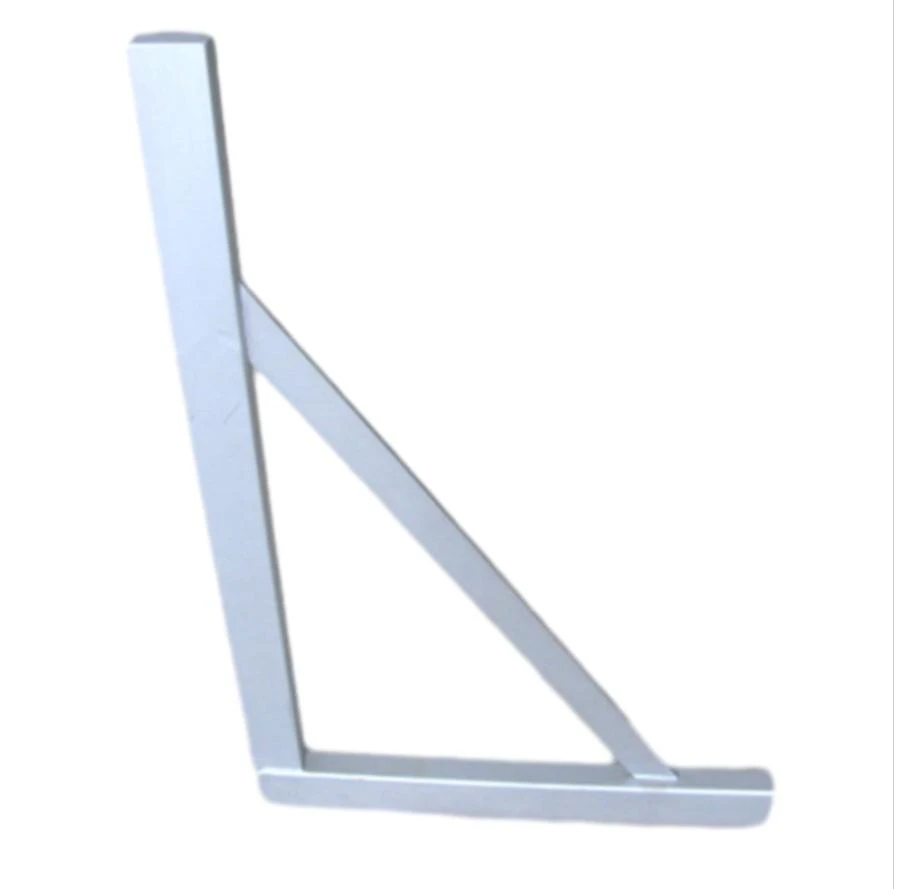

Right Angle Ruler Tool for Woodworking

Precision woodworking requires accurate measuring tools, and the right angle ruler is an essential instrument for perfect 90° measurements.

Precision Frame Level Calibration Steps

Accurate measurement requires properly calibrated instruments, especially when working with frame levels.