Soft Seal Gate Valve

Product Description

|

Type: |

Gate Valve |

Connection |

Flange Ends |

|

Temperature: |

0-80℃ |

Pressure |

PN10/16 |

|

Material: |

Ductile Iron QT450-10 |

Media: |

Water, Gas Oil Etc |

|

Structure: |

Control |

Port Size: |

DN50 |

|

High Light: |

DN50 Soft Seal Gate Valve , Flanged Sockets Soft Seal Gate Valve , Water GGG50 Gate valve |

||

1 Flat bottom seat

The traditional gate valve is often in the water after washing the pipe because of external objects such as stones, wood blocks, cement, paper scraps, sundries, and other silt accumulated in the bottom of the valve groove, easy to cause can not close and form water leakage phenomenon. The bottom of the soft seal gate valve adopts the same flat bottom design as the water pipe, which does not easily cause debris silting and makes the fluid unobstructed.

2 Whole package

The valve uses high-quality rubber for the whole inside, outsourcing glue, domestic first-class rubber vulcanization technology makes vulcanized valve can ensure accurate geometry, and rubber and ductile iron valve then firm, not easy to fall off and elastic memory is good.

3 corrosion

The valve body is coated with powder epoxy resin to prevent corrosion and rust. And can be used in sewage systems. In the past, the traditional cast iron gate valves were often broken due to the impact, collision, or overlap of external objects. Due to the use of nodular cast iron, this situation has been greatly reduced.

4 three "O" type

Because the valve stem uses three "O" type ring seal ring designs. It can reduce the friction resistance when the switch, greatly reduce the phenomenon of water leakage, and can not stop the construction of a replacement seal ring.

5 helps to drink raw

As the valve body is coated with non-toxic epoxy resin, the internal and external surfaces of the gate valve are completely covered with rubber to prevent rust or corrosion.

6 Cast valve body

The valve body is precision cast and the precise geometry ensures the valve sealing without any finishing in the north of the valve body.

7 lightweight

The body is made of ductile casting, the weight is reduced by about 20% to 30% compared with the traditional gate valve, which is convenient for maintenance.

What is a Soft Seal Gate Valve

A Soft Seal Gate Valve is a critical component in various industrial applications, offering an effective solution for controlling the flow of liquids and gases. Unlike traditional gate valves that often rely on metal-to-metal seating surfaces, the Soft Seal Gate Valve incorporates a soft sealing material, typically made from rubber or elastomer, which enhances its sealing capabilities. This design enables a tighter seal, reducing the risk of leaks and ensuring greater operational efficiency.

The primary advantage of a Soft Seal Gate Valve lies in its ability to provide a higher level of performance compared to conventional gate valves. The soft sealing material accommodates minor irregularities on the valve seat, leading to improved sealing effectiveness. This characteristic makes the Soft Seal Gate Valve particularly suitable for applications where a tight shut-off is crucial, such as in water supply systems, chemical processing plants, and wastewater treatment facilities.

Moreover, Soft Seal Gate Valves are known for their versatility and ease of use. They come in various sizes and configurations, making them adaptable to different piping systems. The straightforward design allows for quick installation and maintenance, providing operators with a reliable solution that minimizes downtime. Additionally, the absence of hard metallic contact between the sealing surfaces helps to reduce wear and extend the lifespan of the valve.

In summary, the Soft Seal Gate Valve stands out as a superior choice for many fluid handling applications. Its soft sealing technology enhances performance, reduces leakage, and improves overall system reliability. Whether you're involved in manufacturing, construction, or facility management, understanding the benefits of a Soft Seal Gate Valve is essential for optimizing your operations and ensuring sustainable performance over time.

The Differences Between Soft Seal Gate Valve and Hard Seal Gate Valve

In the world of industrial piping systems, valves play a quintessential role in regulating the flow of fluids. Among the various types of valves available, soft seal gate valves and hard seal gate valves are often compared for their unique characteristics and applications.

What is a Soft Seal Gate Valve?

A Soft Seal Gate Valve utilizes a resilient material, usually rubber or elastomer, as the sealing element between the valve body and the disc. This design allows for a tight seal when the valve is closed, preventing any fluid leakage. Soft Seal Gate Valves are typically favored in applications involving water, wastewater, or low-pressure systems where a high level of leak-proof performance is desired.

Key Features of Soft Seal Gate Valves:

1. Flexibility: The soft sealing material conforms to the seat when closed, ensuring a tight seal.

2. Lower Operating Torque: The design requires less force to operate compared to hard seal valves, making them easier to use.

3. Suitable for Various Fluids: These valves can be used effectively in diverse applications, particularly with non-corrosive fluids.

What is a Hard Seal Gate Valve?

Conversely, a Hard Seal Gate Valve is designed with a hard sealing surface, typically made from metal or ceramic. This type of valve features a more rigid structure, providing higher resistance to pressure and temperature fluctuations. Hard Seal Gate Valves are generally employed in applications that involve high-pressure fluids, corrosive environments, or situations requiring a robust sealing option.

Key Features of Hard Seal Gate Valves:

1. Durability: The hard sealing surface offers better resilience against abrasive and corrosive materials.

2. High-Pressure Capability: These valves can withstand considerable pressure, making them suitable for heavy-duty applications.

3. Longevity: Due to their tough materials, hard seal valves tend to have a longer operational life in harsh environments.

Major Differences Between Soft Seal Gate Valve and Hard Seal Gate Valve

1. Sealing Mechanism: The primary difference lies in the sealing mechanism. Soft Seal Gate Valves use elastic materials for sealing, while Hard Seal Gate Valves utilize metallic or ceramic surfaces, making them fundamentally different in performance and intended usage.

2. Pressure and Temperature Tolerance: Hard Seal Gate Valves are generally used in high-pressure and high-temperature applications, whereas Soft Seal Gate Valves are best suited for lower-pressure situations.

3. Maintenance and Cost: Soft Seal Gate Valves often require more frequent maintenance and replacements due to wear and tear on the sealing material. In contrast, Hard Seal Gate Valves typically have lower maintenance demands but may come at a higher initial cost.

4. Flow Characteristics: Soft Seal Gate Valves tend to offer smoother flow characteristics in non-abrasive fluids, while Hard Seal Gate Valves can manage heavy-duty and high-viscosity fluids more effectively due to their construction.

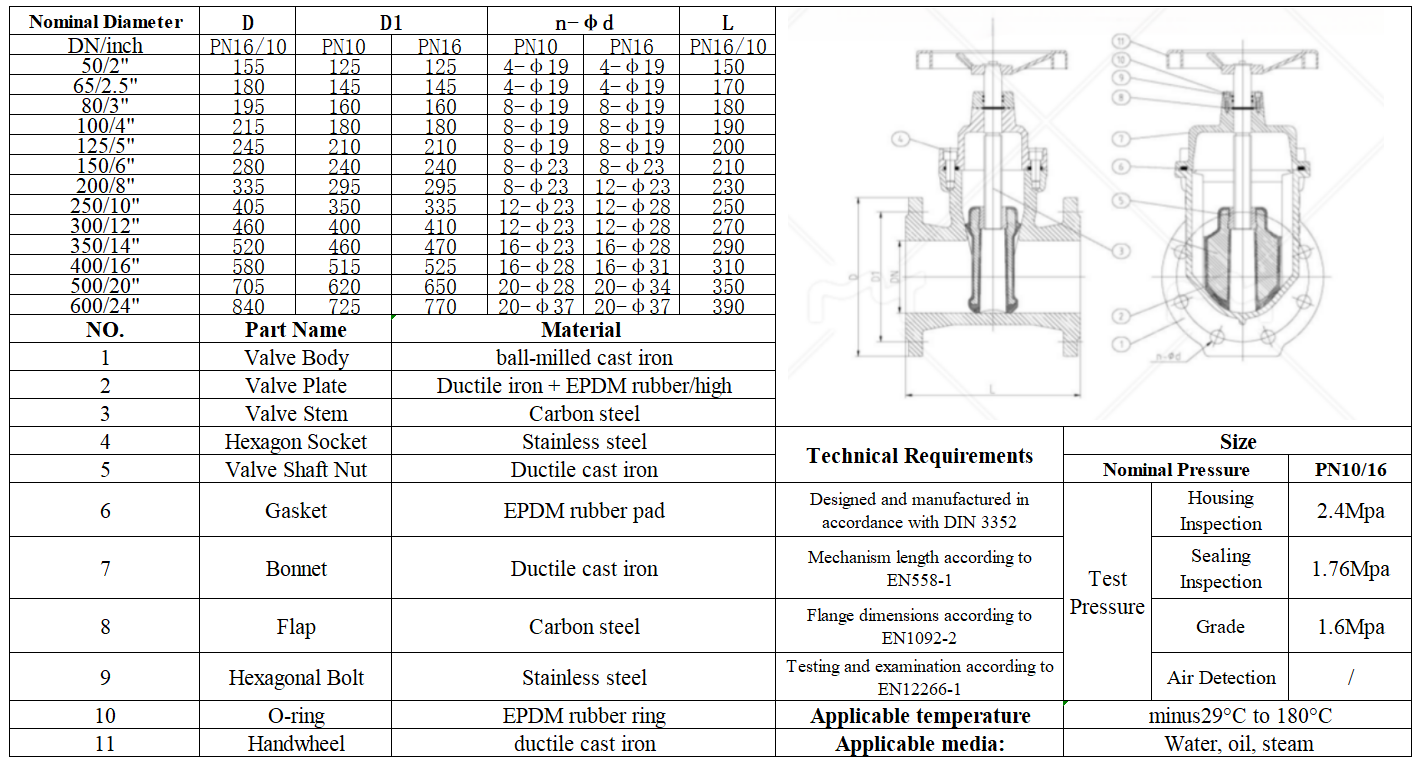

Product Detail Drawing

Product Parameter

Soft Seal Gate Valve FAQs

Q: How long is your delivery time?

A: Generally it is 15-30 days. If the goods are in stock for 5 days or if the material is not in stock it requires 10 days above, it is according to quantity.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What are your terms of payment?

A: Payment<= 1000 USD, 100% in advance. Payment>= 1000 USD, 30% T/T in advance, balance before shipment.

Q: What is a Soft Seal Gate Valve and what are its primary uses?

A: A Soft Seal Gate Valve is a type of valve primarily used to control the flow of liquids and gases in various piping systems. Designed with a flexible sealing element, it provides a tight closure, ensuring minimal leakage. This valve is ideal for applications such as water supply systems, sewage treatment, and industrial processes where reliable sealing is crucial. Its versatility and efficiency make it a popular choice in commercial and residential installations.

Q: What materials are used in the construction of the Soft Seal Gate Valve?

A: Our Soft Seal Gate Valve is constructed from high-quality materials, including robust cast iron or ductile iron for the body, and a soft sealing component made from durable elastomers or Teflon. These materials are selected for their exceptional corrosion resistance, durability, and ability to withstand varying temperatures and pressures, ensuring long-lasting performance in demanding environments.

Q: How do I know if this valve is suitable for my system?

A: To determine if the Soft Seal Gate Valve is suitable for your system, consider the following factors: the type of fluid being transported (liquid or gas), the operational pressure and temperature, and the required sealing performance. If you need further assistance, please consult with your system engineer or reach out to our customer support team for tailored recommendations based on your specific application needs.

Q: Is installation of the Soft Seal Gate Valve difficult?

A: The installation of the Soft Seal Gate Valve is generally straightforward and can be performed by professionals familiar with plumbing or piping systems. It typically requires standard tools and follows common valve installation practices. For best results and to ensure optimal performance, we recommend consulting the installation manual provided with the valve or hiring a qualified technician.

Q: What maintenance is required for the Soft Seal Gate Valve?

A: Regular maintenance ensures the longevity and proper functioning of the Soft Seal Gate Valve. We recommend periodically inspecting the valve for leaks or signs of wear. Cleaning the valve and the surrounding area can help prevent debris buildup that might affect performance. Additionally, ensure that the valve operates smoothly by exercising it every few months, which helps keep the sealing elements flexible. For any issues beyond routine maintenance, please consult our technical support team.

Q: Can the Soft Seal Gate Valve handle high pressure?

A: Yes, our Soft Seal Gate Valve is designed to handle a range of pressures, making it suitable for various applications, including high-pressure systems. However, it is essential to verify the specific pressure ratings provided in the product specifications to ensure it meets your particular requirements. If you have a unique application in mind or need assistance, feel free to contact us for more detailed information and guidance.

Related PRODUCTS

RELATED NEWS

Thread Plug Gauge Our Promise of Measurement Excellence

At Storaen (Cangzhou) International Trading Co., we manufacture precision thread plug gaug

Gauge Pin Class Reflecting Quality Legacy

At Storaen (Cangzhou) International Trading Co., we manufacture precision pin gauge i

Check Valve Types for High Rise Buildings

At Storaen (Cangzhou) International Trading Co., we specialize in engineering premium chec