Hard seal gate valve

Product Description

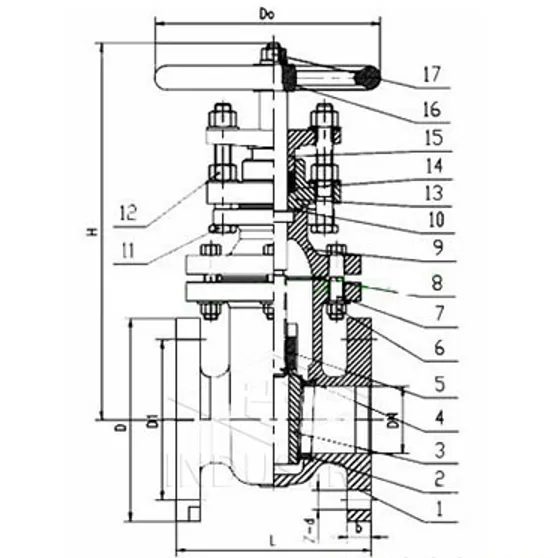

uctile Iron Concealed Lever Hard Seal Gate Valves (DN40-DN2000), Pressure: (PN6~PN25), All products are certified by CE pressure equipment.

Size range: 1 1/2‘-12’/DN40-DN300

Operation mode: manual/gear box/pneumatic/electric

Working pressure: PN16

Valve body material: cast iron / ductile iron

Valve plate material: cast iron/ductile iron

Valve seat material: brass/bronze/stainless steel

Valve stem material: SS

Gland material: cast iron / ductile iron

Application: water, oil and gas

Shell test: 1.5 times

Seat test: 1.1 times

Payment method: T/T

Lead time: 5-30 days

Product Features

1. Exquisite selection of materials, in line with relevant standards, and high quality materials.

2. The valve fully meets the requirements of the standard, with reliable sealing, excellent performance and beautiful appearance.

3. The sealing pair is advanced and reasonable. The sealing surfaces of the gate and the valve seat are reliable, high hardness, wear resistance, high temperature resistance, and high temperature resistance. Good corrosion and scratch resistance and long life.

4. After quenching and tempering and surface nitriding treatment, the valve stem has good corrosion resistance, scratch resistance and wear resistance.

5. It adopts wedge-type elastic gate structure, middle and large diameters are equipped with thrust bearings, the friction is small, and it is equipped with impact manual operation, which can be opened and closed easily.

Design advantages

1. The fluid resistance is small, and the sealing surface is less brushed and corroded by the medium.

2. It saves effort to open and close.

3. The flow direction of the medium is not restricted, does not disturb the flow, and does not reduce the pressure.

4. Simple shape, short structure length, good manufacturing technology and wide application range.

Field of Application

Size Range: DN40 to DN300

Temperature: (-)29℃ to 425℃

Allowable Operating Pressure:PN16

Gate valve is widely used in petrochemical plants, metallurgy, water treatment, thermal power plants and other oil and water vapor pipelines to connect or cut off the medium in the pipeline.

Installation and maintenance

1. Handwheels, handles and transmission mechanisms are not allowed to be used for lifting, and collisions are strictly prohibited.

2. The double gate valve should be installed vertically (that is, the valve stem is in the vertical position and the handwheel is on the top).

3. The gate valve with bypass valve should be opened before opening (to balance the pressure difference between inlet and outlet and reduce the opening force).

4. The gate valve with drive mechanism should be installed according to the product manual.

5. If the valve is frequently opened and closed, lubricate at least once a month.

Product Parameter

|

DN |

Inch |

L |

PCD |

n-φd |

FOD |

|

40 |

1 1/2" |

140 |

98.4 |

4-18 |

165 |

|

50 |

2" |

146 |

114 |

4-18 |

165 |

|

65 |

2 1/2" |

159 |

127 |

4-18 |

185 |

|

80 |

3" |

165 |

146 |

8-18 |

200 |

|

100 |

4" |

172 |

178 |

8-18 |

220 |

|

125 |

5" |

191 |

210 |

8-18 |

250 |

|

150 |

6" |

210 |

235 |

8-22 |

285 |

|

200 |

8" |

241 |

292 |

12-22 |

340 |

|

250 |

10" |

273 |

356 |

12-26 |

405 |

|

300 |

12" |

305 |

406 |

12-26 |

460 |

Advantages of Hard Seal Gate Valves

One prominent feature of hard seal gate valves is their superior sealing capability. These valves are designed with a robust sealing mechanism that minimizes leakage, effectively preventing any fluid or gas from passing through when the valve is in a closed position. This quality is particularly important in applications where preventing contamination and protecting the environment are crucial.

Another significant advantage of hard seal gate valves is their extended lifespan. Made from durable materials such as stainless steel or other hard alloys, these valves are engineered to withstand harsh operating conditions, including high pressure and extreme temperatures. This durability translates into lower maintenance costs and less frequent replacements, making them a cost-effective solution for industrial applications.

Additionally, hard seal gate valves provide excellent flow characteristics. Their design allows for minimal flow resistance, enabling smooth and efficient fluid transfer. This not only enhances system performance but also reduces energy consumption, aligning with modern sustainability goals in various sectors, including water treatment, chemical manufacturing, and oil and gas.

Furthermore, the ease of operation of hard seal gate valves contributes to their popularity. They can be operated manually or automatically, allowing for flexibility in various installations. This adaptability ensures that systems can be tailored to meet specific operational needs without compromising on efficiency or safety.

In conclusion, hard seal gate valves offer many advantages, including enhanced sealing performance, durability, excellent flow characteristics, and ease of operation. These benefits make them an essential component in many industrial processes, ensuring reliability and efficiency. As industries continue to evolve, the role of hard seal gate valves will undoubtedly grow, solidifying their position as a key element in modern engineering solutions.

Hard Seal Gate Valves FAQs

What is a Hard Seal Gate Valve, and what are its primary applications?

A Hard Seal Gate Valve is a type of valve that ensures a tight seal with minimal leakage, making it ideal for applications requiring unimpeded flow. They are commonly used in industries such as water supply, petroleum, and chemical processes, where reliable isolation and control of fluid flow are crucial. Their robust design helps in handling fluid pressure and temperature extremes, making them suitable for both industrial and commercial settings.

What materials are used in the construction of Hard Seal Gate Valves?

Our Hard Seal Gate Valves are typically constructed from high-quality materials such as stainless steel, cast iron, and carbon steel, designed for durability and longevity. The sealing surfaces are engineered for optimal performance, often featuring hard facing materials that enhance their resistance to wear and corrosion. Depending on your specific needs, we offer valves that can handle various chemicals and fluids efficiently.

How do I know what size Hard Seal Gate Valve is right for my system?

Choosing the right size for your Hard Seal Gate Valve is crucial for optimal performance. You should consider the diameter of the pipe, the flow rate required, and any specific system requirements such as pressure and temperature ratings. If you’re unsure, we recommend consulting with a professional engineer or reaching out to our customer service team for assistance; we can provide guidance based on your system’s specifications to ensure you select the perfect valve.

Are Hard Seal Gate Valves easy to install and maintain?

Yes, Hard Seal Gate Valves are designed for straightforward installation and maintenance. They come with comprehensive installation instructions and can be installed in various orientations. Regular maintenance is minimal, often requiring just periodic inspections to ensure seals remain effective. Our team is available to provide support and advice on maintenance procedures to help prolong the valve’s lifespan.

Do Hard Seal Gate Valves comply with industry standards?

Absolutely, our Hard Seal Gate Valves are manufactured to meet or exceed industry standards such as ANSI, API, and ASME. We ensure that each valve undergoes rigorous testing for quality and performance, providing you with a product that you can trust for your applications. If you require specific certification or compliance documentation, please let us know, and we will be happy to assist.

Can Hard Seal Gate Valves be used in high-pressure applications?

Yes, Hard Seal Gate Valves are well-suited for high-pressure applications. They feature robust construction and advanced sealing technologies designed to withstand such demanding conditions. When selecting a valve for high-pressure use, be sure to check its pressure rating and consult with our team if you have any questions; we can recommend the best options tailored to your specific requirements.

Related PRODUCTS

RELATED NEWS

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal Systems

A flanged gate valve is an essential element in fluid control systems across multiple industries, known for its robust construction and leak-proof connection.

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline Control

In today’s fast-paced industrial and municipal applications, the importance of reliable valve performance cannot be overstated.

Gate Valve Types: Understanding the Options for Your Pipeline Systems

Gate valves are a critical component in various piping systems, used to start or stop the flow of liquid or gas.