Ring Gauge

Product Description

Smooth ring gauge: It is a type of gauge used to measure the outer diameter dimension of the workpiece, divided into T end and Z end. In use, the T end represents the upper limit dimension of the outer diameter of the workpiece and should pass; the Z end represents the lower limit dimension of the outer diameter of the workpiece and cannot pass.

Our company produces gauge series: Thread Gauge (Metric, American, English, Trapezoidal), and Thread Plug Gauge, Thread Ring Gauge, Smooth Plug Gauge, Smooth Ring Gauge Trapezoidal), Plug Gauge, Smooth Ring Gauge, Card Gauge, Keyway Plug Gauge, Mohs Gauge, 7:24 Taper Gauge, Metric Taper Gauge, Sinusoidal Gauge, Inspection Rods (Mohs, 7:24, Metric), Cylindrical Angle Ruler, Various Non-Standard Checks and Measuring Instruments Thread Checks, Coaxial Checks, and other non-standard checking instruments.

Ring Gauge Use

A ring gauge is a precision measuring tool used primarily in machining and quality control to measure the external dimensions of cylindrical objects, such as shafts or bearings. It is designed to check the size and roundness of these components, ensuring they meet specific tolerance requirements. Ring gauges are commonly used in industries such as automotive, aerospace, and manufacturing, where maintaining precise dimensions is crucial.

Ring gauges come in two main types: Go/No-Go gauges and set-ring gauges. The Go/No-Go type is used for basic tolerance checking. It consists of two rings: the "Go" ring and the "No-Go" ring. The "Go" ring should fit the part, indicating that the component is within the desired size range, while the "No-Go" ring should not fit, indicating the part exceeds the specified dimensions.

The set-ring gauge is used for more detailed measurement and calibration. This type consists of a precisely manufactured ring that serves as a standard to compare against the component being measured. It helps verify that components maintain consistent size throughout production processes.

Ring gauges are made from materials with low expansion rates, such as steel or carbide, to ensure they maintain their precision even under varying temperature conditions. When using a ring gauge, it is essential to handle it carefully to avoid damage, as even a small imperfection can affect measurement accuracy.

In summary, ring gauges are vital for ensuring high-precision measurement of cylindrical parts in various industries. Their use helps prevent defects and ensures components fit and function as intended, contributing to the overall quality and performance of mechanical systems.

What is the Advantage of Ring Gauge?

In the manufacturing and engineering industries, ensuring precise measurements is crucial for the quality and performance of components. One essential tool that plays a significant role in achieving accurate measurements is the ring gauge. This specialized measuring instrument provides numerous advantages that enhance productivity and quality assurance processes.

First and foremost, the primary advantage of a ring gauge is its ability to provide highly accurate measurements for cylindrical parts. Its design allows users to check the diameter of a workpiece effectively. Ring gauges are manufactured to stringent tolerances, making them ideal for quality control in rigorous environments. This precision helps to ensure that parts fit together seamlessly, reducing the likelihood of assembly issues.

Another prominent advantage of the ring gauge is its simplicity of use. Unlike more complex measuring tools, ring gauges present a straightforward 'go/no-go' method for inspection. The design consists of two rings – a go ring that should fit onto the part and a no-go ring that should not. This binary approach allows for quick assessments, enabling operators to identify non-conforming parts swiftly without the need for intricate measurement setups.

Moreover, ring gauges are highly durable and can withstand extensive use, leading to a long lifespan and reduced costs in the long run. They are often made from hard materials that resist wear and tear, making them suitable for repetitive daily checks in various production settings.

Lastly, implementing a ring gauge in your quality control process can significantly enhance the overall efficiency and reliability of manufacturing operations. Ensuring that every manufactured piece meets the required specifications not only elevates product quality but also fosters customer satisfaction and trust.

In conclusion, the advantages of using a ring gauge are multifaceted, encompassing accuracy, user-friendliness, durability, and efficiency. By integrating ring gauges into your manufacturing processes, you can achieve enhanced quality control and improve the overall standard of your products.

Product Detail Drawing

Ring Gauge Specification

Smooth ring gauge

standard: GB1957-81 DIN7162

accurate:h6 h7 h8 h9

Unit: mm

|

1.8 |

16 |

34 |

62 |

120 |

|

2.0 |

17 |

35 |

65 |

125 |

|

2.5 |

18 |

36 |

68 |

130 |

|

3.0 |

19 |

37 |

70 |

135 |

|

3.5 |

20 |

38 |

72 |

150 |

|

4.0 |

21 |

39 |

75 |

165 |

|

4.5 |

22 |

40 |

80 |

180 |

|

5.0 |

23 |

42 |

82 |

200 |

|

6.0 |

24 |

44 |

85 |

220 |

|

7.0 |

25 |

45 |

88 |

240 |

|

8.0 |

26 |

46 |

90 |

250 |

|

9.0 |

27 |

47 |

92 |

260 |

|

10.0 |

28 |

48 |

95 |

280 |

|

11.0 |

29 |

50 |

98 |

300 |

|

12.0 |

30 |

52 |

100 |

|

|

13.0 |

31 |

55 |

105 |

|

|

14.0 |

32 |

58 |

110 |

|

|

15.0 |

33 |

60 |

115 |

STORAEN Ring Gauge Specification: Dual Standard Certified in Accordance with GB1957/DIN7162

STORAEN’s ring gauges stand as a testament to precision engineering, meticulously designed to comply with both GB1957 and DIN7162 international standards—two benchmarks of excellence in dimensional metrology. Engineered to achieve accuracy up to h6 class, these gauges serve as master ring gages, setting the gold standard for bore diameter measurements in industries where precision is non-negotiable, from automotive manufacturing to aerospace engineering and industrial machinery production.

Crafted from premium-grade alloy steel, our steel ring gauges undergo a rigorous heat-treatment process to enhance hardness and resist wear, ensuring consistent performance even in harsh industrial environments. The material’s low thermal expansion coefficient minimizes errors caused by temperature fluctuations, a critical feature for maintaining reliability in global manufacturing settings. Each gauge features a polished surface finish, reducing friction during measurements and protecting against accidental scratches that could compromise accuracy.

Our product range includes both plain ring gages for single-dimension inspections and ring gauge sets that bundle multiple sizes, ideal for workshops requiring versatile quality control solutions. Whether you need a gauge for verifying the inner diameter of a precision-machined bearing or calibrating the bore of a hydraulic component, STORAEN offers configurations that align with your specific needs. All gauges adhere to the Go/No-Go measurement principle: the "Go" end confirms a part’s dimensional conformity, while the "No-Go" end ensures it does not exceed allowable tolerances, streamlining inspection processes for efficiency.

The ring gauge class h6 designation signifies our commitment to ultra-tight tolerances—typically within ±0.0005mm for nominal sizes up to 50mm—making our gauges suitable for applications demanding micron-level precision. This level of accuracy is validated through our in-house calibration laboratories, equipped with advanced interferometers and coordinate measuring machines (CMMs), ensuring each gauge meets or exceeds the strictest international tolerance standards. Every product is accompanied by a traceable calibration certificate, linking its performance to national metrology standards for full compliance documentation.

For customers seeking ring gauges for sale, STORAEN provides a comprehensive specification table covering nominal sizes from 1.8mm to 300mm, with options for both metric and inch-based measurements. Beyond standard offerings, we specialize in custom solutions, including non-standard diameters, special surface coatings (such as chrome plating for enhanced corrosion resistance), and tailored ring gauge measurement systems for unique industrial applications. Our engineering team works closely with clients to design gauges that address specific challenges, from measuring deep bores in aerospace components to inspecting the inner diameters of miniature medical devices.

Choosing STORAEN means investing in more than just a tool—you gain a partner in quality assurance. Our ring gauges for sale are backed by a lifetime warranty against material defects, alongside access to our global technical support network. Whether you’re a small machine shop or a large-scale manufacturer, our products deliver the reliability and precision needed to maintain production efficiency and reduce costly rework. Trust in STORAEN’s decades of expertise in metrology: our gauges are not just instruments; they’re the foundation of your quality control framework.

STORAEN's After-sales System for Inspection Tools: Full-cycle Guarantee from Standard Products to Non-customized Inspection Tools

STORAEN’s after-sales system for ring gauges is more than a service—it’s a commitment to ensuring your measurement tools deliver consistent precision throughout their lifecycle. Whether you’ve purchased our standard ring gauge products or collaborated with us on non-custom inspection tools, we provide end-to-end support that spans calibration, maintenance, and technical expertise, reinforcing our role as your trusted partner in quality control.

For customers who buy ring gauges for sale from our standard range—including plain ring gauges, ring gauge sets, and master ring gauges—we start with traceable calibration certificates that validate compliance with GB1957, DIN7162, and international ring gauge class standards (up to h6 precision). Our global service centers offer annual recalibration services, using state-of-the-art interferometers to ensure your gauges maintain accuracy even after years of use. This is critical for industries like aerospace and automotive, where ring gauge measurement reliability directly impacts production quality and compliance documentation.

For non-custom non-standard inspection tools, our engineering team provides tailored support from design to deployment. If your unique application requires a steel ring gauge with specialized coatings, extended size ranges, or custom tolerance specifications, we offer post-purchase modifications and retrofitting services. Our technicians work closely with your team to troubleshoot measurement challenges, whether it’s optimizing a ring gauge set for high-volume production lines or resolving compatibility issues in complex machining environments.

Every STORAEN ring gauge—regardless of type—comes with a lifetime warranty against material defects, reflecting our confidence in the durability of our steel and carbide constructions. For wear and tear from normal use, we provide cost-effective repair solutions, including surface reconditioning for polished finishes and dimensional revalidation for gauges exposed to extreme working conditions. Our goal is to extend the operational life of your tools, reducing replacement costs while maintaining the precision your processes depend on.

Technical support is at the core of our after-sales philosophy. Our 24/7 customer service team—staffed by metrology experts—offers remote troubleshooting for measurement discrepancies, helping you distinguish between tool-related issues and process errors. We also provide free instructional resources, such as video guides on proper ring gauge handling, storage best practices to prevent corrosion, and tips for integrating gauges into automated quality control systems.

Choosing STORAEN means gaining peace of mind through an after-sales ecosystem that prioritizes your operational efficiency. Whether you’re using a single plain ring gage for basic inspections or a complex master ring gage for ISO certification audits, our support grows with your needs. We don’t just sell tools; we ensure they remain vital assets in your quality assurance framework, backed by the expertise and resources of a global leader in precision metrology. Trust in STORAEN to keep your measurements accurate, your processes compliant, and your business moving forward—today and for years to come.

On-site pictures

Related PRODUCTS

RELATED NEWS

Why Metric Trapezoidal Thread is Ideal for Precision Motion Control

In precision motion control systems, the choice of thread design directly impacts performance, and metric trapezoidal thread has emerged as a superior solution for its unique combination of accuracy and durability.

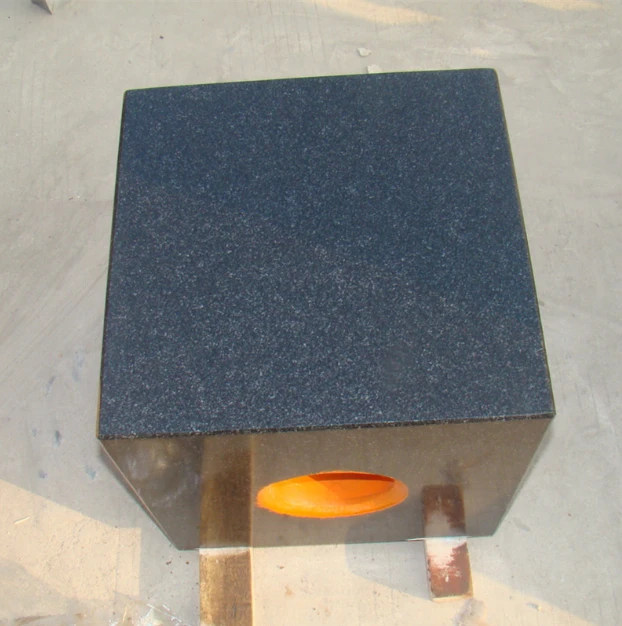

The Unique Properties of a Block of Granite for Industrial Use

In industrial manufacturing and precision measurement, the reliability of materials directly impacts operational accuracy, and a block of granite has emerged as an indispensable resource.

The Role of Flanged Y Strainers in Preventing Pipeline Clogs

In industrial pipeline systems, maintaining unobstructed flow is critical to operational efficiency, and flanged y strainer has emerged as a key component in achieving this goal.