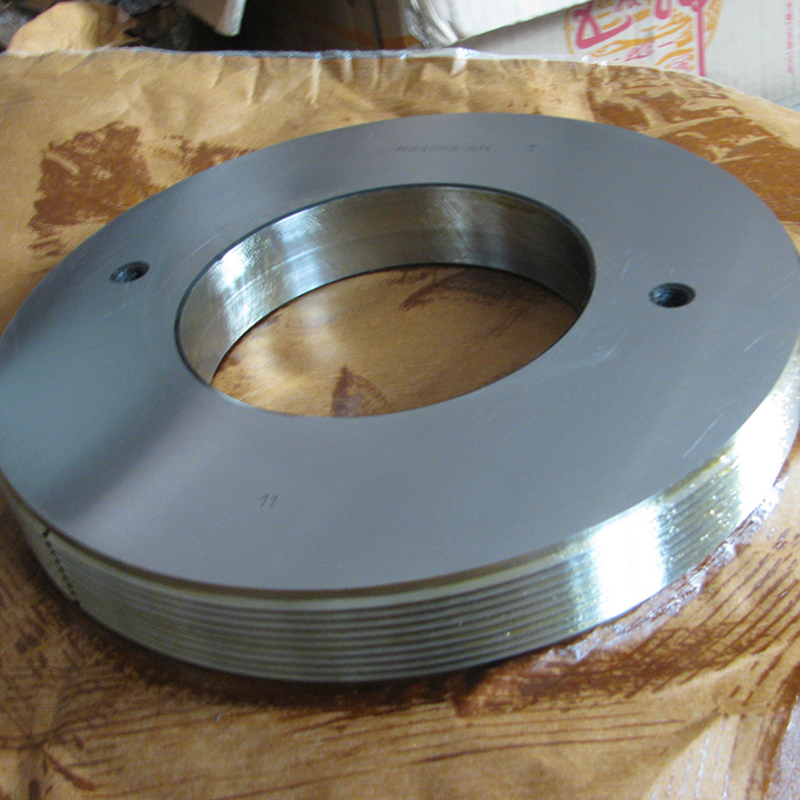

Threaded Ring Gauge

Product Description

What Is Thread Ring Gauge

A thread ring gauge is a precision tool used to inspect and verify the accuracy of external threads on a workpiece, ensuring they conform to specified dimensions and tolerances. Commonly employed in manufacturing, especially in industries involving screws, bolts, and other threaded fasteners, this gauge is essential for maintaining thread quality and ensuring compatibility between components.

The design of a thread ring gauge is typically cylindrical, with an internal thread that matches the desired external thread profile of the part being tested. It is used primarily for checking the size and pitch of external threads on male parts like bolts, shafts, and screws. The gauge is typically available in two forms: Go and No-Go.

Go Gauge:

Technical Specifications and Size Range of Threaded Ring Gauges(H2)

STORAEN’s threaded ring gauges are precision-engineered to meet the diverse dimensional control needs of global manufacturing, offering a comprehensive range of technical specifications and sizes that align with international standards and industry demands. As a leading provider of thread gauge ring solutions, we ensure our tools deliver accuracy, reliability, and versatility—whether for standard metric threads or specialized applications like NPT thread ring gauges.

Size Range: Covering Every Threaded Application

Our gauges span a wide nominal diameter spectrum, from 0.8mm (M1) for miniature precision components to 300mm (M300) for heavy-duty industrial threads, accommodating types of thread plug gauges across coarse, fine, and pipe thread classifications:

Metric Threads (ISO):Standard sizes like M6×1, M24×1.5, and large-diameter M120×3, ideal for automotive and machinery applications;

NPT Threads (ASME B1.20.1):Conical pipe threads such as 1/8"NPT, 2"NPT, designed for leak-proof pipe connections in oil, gas, and plumbing industries;

BSP/ISO 7-1 Threads:Parallel (G1/2) and tapered (R1/4) variants for European and global pipe systems, ensuring seamless compatibility.

Precision Grades: Defining Accuracy Standards

STORAEN’s threaded ring gauges adhere to strict accuracy classes (h6 to h9), with h6 as the premium grade for critical applications requiring micron-level tolerance control (e.g., ±0.002mm for M10×1.5). Each gauge undergoes rigorous calibration against thread ring gauge standard references like DIN 13, ASME B1.1, and GB/T 197, accompanied by traceable certification to validate compliance with ISO 9001 quality systems. The Go/No-Go dual-end design ensures quick, reliable verification of thread fit, reducing the use of thread gauge complexity on the shop floor.

Material & Construction: Built for Longevity

Crafted from high-grade GCr15 bearing steel (hardened to 62HRC) or tungsten carbide, our thread gauge ring solutions resist wear and thermal expansion, maintaining accuracy in harsh machining environments. Key structural features include:

Ergonomic Handles:For diameters >100mm, dual-handle designs enhance grip and control during heavy-duty inspections;

Superfinished Surfaces:A mirror-like Ra 0.05μm finish minimizes friction and prevents burr accumulation, protecting both the gauge and workpiece;

Corrosion-Resistant Coatings:Optional TiN or chromium plating for extended life in aggressive industrial settings.

Customization & Compliance

Beyond standard offerings, we specialize in non-standard solutions for unique thread profiles, including acme, buttress, or proprietary designs. Our engineering team works closely with clients to tailor specifications such as pitch, thread angle, and tolerance grades, ensuring alignment with project-specific requirements—all while maintaining competitive thread ring gauge price without compromising quality.

Trust in STORAEN for Precision & Performance

Whether you need a NPT thread ring gauge for pipe fitting inspections, a metric threaded ring gauge for automotive parts, or a custom solution for aerospace fasteners, STORAEN’s technical specifications and size range deliver unmatched adaptability. With our commitment to international standards, durable construction, and flexible customization, we empower manufacturers to achieve precision at every thread, making us the preferred choice for quality control professionals worldwide.

This is the functional gauge that checks whether the thread is within the acceptable limits for size and pitch. If the male thread fits into the Go gauge, it indicates that the thread has met the minimum acceptable tolerance.

No-Go Gauge: This gauge checks whether the thread exceeds the maximum allowable tolerance. If the male thread fits into the No-Go gauge, it indicates that the thread is out of tolerance and should be rejected.

Thread ring gauges are made of high-grade materials such as tool steel or carbide, ensuring durability and resistance to wear. To maintain accuracy, they are carefully calibrated and periodically inspected for wear. Thread gauges are also marked with specific details about the type of thread they are designed to measure, such as the pitch, diameter, and thread form.

Thread Ring Gauges Use

A thread ring gauge, often referred to as a thread gauge, is primarily used to verify the pitch, diameter, and form of external threads on parts such as bolts, screws, and other fasteners. Its design typically resembles a ring, allowing for easy placement on the threaded component, which enables a quick and efficient inspection process. The gauge not only confirms whether the thread is within tolerance but also identifies any deviations that could affect the component's performance or fit.

Utilizing a thread ring gauge is essential for manufacturers striving for precision in their operations. The accuracy of the measurement ensures that the components will mesh correctly with corresponding internal threads, preventing failures that could lead to increased production costs and compromised safety. Moreover, regular use of thread ring gauges in quality control processes can greatly enhance the reliability of production lines, thus leading to higher customer satisfaction.

Why Choose Storaen Thread Ring Gauge Manufacturer

When selecting a thread ring gauge manufacturer, Storaen (Cangzhou) International Trading Co. stands out as a top choice. Renowned for its high-quality manufacturing practices, this company combines precision engineering with an unwavering commitment to customer satisfaction. Based in the industrial hub of Botou, China, Storaen has developed a reputation for producing some of the most reliable and accurate industrial plug gauges for sale available today, including their line of thread ring gauges.

Expertise in Precision Manufacturing

At the heart of Storaen's success is its unparalleled expertise in precision manufacturing. With years of experience in the field, Storaen’s engineers and craftsmen specialize in creating tools that meet the highest industry standards. Their thread ring gauges are meticulously designed to ensure accurate measurements for external threads, providing the essential quality control that industries like automotive, aerospace, and manufacturing require. Whether you're looking for Go or No-Go gauges, Storaen guarantees that each product is manufactured to the tightest tolerances, ensuring flawless functionality.

Cutting-Edge Technology

Storaen stays ahead of the competition by continuously investing in advanced technology and production methods. This forward-thinking approach ensures that the company not only meets but exceeds the stringent demands of the modern manufacturing environment. From the use of high-grade raw materials to the latest machining techniques, Storaen’s thread ring gauges are crafted with the utmost precision and durability in mind. The incorporation of state-of-the-art technology into the production process also enhances the company's ability to deliver high-volume orders with consistent quality, making them an excellent choice for businesses with large-scale needs.

Strategic Location and Competitive Edge

Storaen’s location in Botou, China, is another factor that contributes to its success. The city is known for its rich tradition in casting and industrial manufacturing, providing Storaen with easy access to top-tier raw materials and a skilled labor force. This strategic advantage not only ensures the highest quality of raw materials for its thread ring gauges but also enhances the company’s operational efficiency. By leveraging its location, Storaen is able to provide cost-effective solutions without compromising on quality.

Commitment to Sustainability

Storaen (Cangzhou) International Trading Co. recognizes the importance of sustainability in today’s manufacturing landscape. The company is committed to minimizing its ecological footprint by adopting environmentally responsible practices throughout its operations. This commitment extends to their product line, ensuring that their thread ring gauges and other products are crafted using eco-friendly processes whenever possible.

Customer-Centric Approach

Storaen’s commitment to customer satisfaction sets it apart from other manufacturers. The company actively seeks and values customer feedback, using it to continuously improve its products and services. Whether you need assistance with selecting the right thread ring gauge or require support with custom manufacturing, Storaen’s customer service team is always ready to help. This focus on building long-term relationships with clients has earned Storaen a loyal customer base around the world.

Thread Ring Gauge FAQs

What is the Purpose of a Ring Gauge?

A ring gauge is used to measure the external dimensions and threads of a workpiece. It ensures that the part meets the required specifications for fit, form, and function. Primarily used in quality control, it helps verify the accuracy of threads, ensuring compatibility with corresponding components.

What are the Different Types of Ring Gauges?

Ring gauges come in several types, including go and no-go gauges for checking thread tolerances, plain ring gauges for measuring diameters, and snap gauges for internal measurements. These gauges are designed for various applications, such as verifying thread quality, shaft diameters, or hole dimensions, ensuring precision in manufacturing.

Are Ring Gauges Accurate?

Yes, ring gauges are highly accurate tools used to measure the external threads of components. Manufactured to strict tolerances, they ensure precise verification of thread dimensions, providing reliable checks for quality control. With proper calibration and maintenance, ring gauges offer consistent, high-level accuracy in industrial applications.

The Size of Ring Thread Gauges Available.

Storaen (Cangzhou) International Trading Co. provides thread ring gauges in a wide variety of sizes, catering to different industries and applications. These sizes include, but are not limited to:

Small to Large Diameters: From micro threads (e.g., M1, M2) to larger sizes (e.g., M100, M120) and beyond, depending on customer requirements.

Thread Pitches: Available for both fine and coarse threads, ensuring versatility for different thread types.

Custom Sizes: Storaen can produce thread ring gauges to meet specific customer needs, including unique thread profiles or non-standard dimensions.

These gauges are available in various materials, such as high-grade steel, to ensure durability and accuracy. Storaen's extensive range ensures that all industrial sectors, from automotive to aerospace, can find the precise gauges they need for quality control and production standards.

How Ring Thread Gauges Work?

Ring thread gauges work by measuring the accuracy of external threads on a workpiece. The gauge, with an internal thread profile, checks if the part’s external threads match the desired specifications. A Go gauge ensures the part meets minimum tolerance, while a No-Go gauge confirms it doesn’t exceed maximum limits.

Three Key Industry Advantages of Threaded Ring Gauges: Precision, Efficiency, and Durability

STORAEN’s threaded ring gauges are engineered to deliver unmatched performance in industrial thread inspection, combining three core advantages—precision, efficiency, and durability—that set them apart in manufacturing, aerospace, and energy sectors. As a trusted provider of thread gauge ring solutions, we design our tools to meet the rigorous demands of global supply chains while ensuring cost-effective quality control.

1. Micron-Level Precision for Critical Thread Compliance

At the heart of our threaded ring gauge technology is an uncompromising focus on accuracy, essential for verifying thread dimensions like pitch diameter, thread angle, and lead tolerance. Our gauges adhere to international standards such as ISO 965-1, DIN 13, and ASME B1.2, ensuring compliance with thread ring gauge standard requirements for both metric and inch-based threads—including specialized types like NPT thread ring gauges for pipe fittings. The Go/No-Go design allows instant validation: the "Go" end confirms minimum material condition, while the "No-Go" end checks for maximum allowable tolerance, eliminating guesswork in the use of thread gauge applications. This precision is critical in aerospace fasteners and automotive transmissions, where even minor thread deviations can lead to catastrophic failures.

2. Streamlined Inspection for High-Volume Production Efficiency

STORAEN’s threaded ring gauges are optimized to reduce inspection time by up to 40% compared to manual measurement methods, a game-changer for mass production environments. The intuitive dual-end design enables operators to quickly assess thread conformity without complex calculations, making them ideal for types of thread plug gauges used in automotive part manufacturing or industrial equipment assembly. For large-diameter threads (e.g., M120+), our ergonomic handle designs enhance grip and control, further boosting productivity. By minimizing downtime and rework costs, our gauges offer a tangible return on investment, addressing concerns about thread ring gauge price through long-term efficiency gains.

3. Durability Built for Harsh Industrial Environments

Crafted from premium tool steel (hardened to 60HRC+) or tungsten carbide, our thread gauge ring solutions resist wear and corrosion, maintaining accuracy even after years of heavy use. The surface undergoes superfinishing to achieve a mirror-like Ra 0.05μm finish, reducing friction during measurements and protecting against burrs or scratches that could compromise precision. This durability is especially vital for NPT thread ring gauges used in oil and gas applications, where exposure to harsh chemicals and high-pressure environments demands robust materials. STORAEN’s gauges come with a lifetime warranty against material defects, ensuring they remain reliable assets in your quality control toolkit.

A Solution for Every Thread Inspection Need

Whether you require standard threaded ring gauges for common metric threads, specialized NPT thread ring gauges for pipe connections, or custom solutions for non-standard profiles, STORAEN offers a comprehensive range that balances thread ring gauge price with uncompromising quality. Our commitment to precision, efficiency, and durability makes us the preferred choice for manufacturers worldwide—where every thread counts toward operational excellence. Trust in STORAEN to elevate your thread inspection processes, ensuring compliance, reducing costs, and delivering products that meet the highest global standards.

Technical Specifications and Size Range of Threaded Ring Gauges

STORAEN’s threaded ring gauges are precision-engineered to meet the diverse dimensional control needs of global manufacturing, offering a comprehensive range of technical specifications and sizes that align with international standards and industry demands. As a leading provider of thread gauge ring solutions, we ensure our tools deliver accuracy, reliability, and versatility—whether for standard metric threads or specialized applications like NPT thread ring gauges.

Size Range: Covering Every Threaded Application

Our gauges span a wide nominal diameter spectrum, from 0.8mm (M1) for miniature precision components to 300mm (M300) for heavy-duty industrial threads, accommodating types of thread plug gauges across coarse, fine, and pipe thread classifications:

Metric Threads (ISO):Standard sizes like M6×1, M24×1.5, and large-diameter M120×3, ideal for automotive and machinery applications;

NPT Threads (ASME B1.20.1): Conical pipe threads, such as 1/8"NPT, 2"NPT, are designed for leak-proof pipe connections in the oil, gas, and plumbing industries.

BSP/ISO 7-1 Threads: Parallel (G1/2) and tapered (R1/4) variants for European and global pipe systems, ensuring seamless compatibility.

Precision Grades: Defining Accuracy Standards

STORAEN’s threaded ring gauges adhere to strict accuracy classes (h6 to h9), with h6 as the premium grade for critical applications requiring micron-level tolerance control (e.g., ±0.002mm for M10×1.5). Each gauge undergoes rigorous calibration against thread ring gauge standard references like DIN 13, ASME B1.1, and GB/T 197, accompanied by traceable certification to validate compliance with ISO 9001 quality systems. The Go/No-Go dual-end design ensures quick, reliable verification of thread fit, reducing the use of thread gauge complexity on the shop floor.

Material & Construction: Built for Longevity

Crafted from high-grade GCr15 bearing steel (hardened to 62HRC) or tungsten carbide, our thread gauge ring solutions resist wear and thermal expansion, maintaining accuracy in harsh machining environments. Key structural features include:

Ergonomic Handles:For diameters >100mm, dual-handle designs enhance grip and control during heavy-duty inspections;

Superfinished Surfaces:A mirror-like Ra 0.05μm finish minimizes friction and prevents burr accumulation, protecting both the gauge and workpiece;

Corrosion-Resistant Coatings: Optional TiN or chromium plating for extended life in aggressive industrial settings.

Customization & Compliance

Beyond standard offerings, we specialize in non-standard solutions for unique thread profiles, including acme, buttress, or proprietary designs. Our engineering team works closely with clients to tailor specifications such as pitch, thread angle, and tolerance grades, ensuring alignment with project-specific requirements—all while maintaining competitive thread ring gauge price without compromising quality.

Trust in STORAEN for Precision & Performance

Whether you need a NPT thread ring gauge for pipe fitting inspections, a metric threaded ring gauge for automotive parts, or a custom solution for aerospace fasteners, STORAEN’s technical specifications and size range deliver unmatched adaptability. With our commitment to international standards, durable construction, and flexible customization, we empower manufacturers to achieve precision at every thread, making us the preferred choice for quality control professionals worldwide.

Product Detail Drawing

On-site pictures

Related PRODUCTS

RELATED NEWS

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal Systems

A flanged gate valve is an essential element in fluid control systems across multiple industries, known for its robust construction and leak-proof connection.

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline Control

In today’s fast-paced industrial and municipal applications, the importance of reliable valve performance cannot be overstated.

Gate Valve Types: Understanding the Options for Your Pipeline Systems

Gate valves are a critical component in various piping systems, used to start or stop the flow of liquid or gas.