Jan . 09, 2025 11:46 Back to list

Electric soft seal gate valve

Different valve types play a crucial role in regulating the flow of fluids and gases in a wide range of industrial and domestic applications. Understanding the nuances of various valve types can significantly enhance efficiency and safety in systems. Let’s explore some popular valve types, emphasizing their applications and unique attributes.

Needle valves provide precise control in low flow systems, thanks to their slender, tapered point at the end of the valve stem. Their ability to finely adjust flow rates makes them indispensable in applications where accuracy is crucial, such as fuel regulation in engines and flow metering in scientific instrumentation. Diaphragm valves utilize a flexible diaphragm to create a tight seal. This design is beneficial for corrosive or viscous fluids as it isolates the fluid from the moving mechanical components. Industries dealing with slurries or corrosive chemicals, such as mining and biopharmaceuticals, often employ diaphragm valves for their reliability and ease of maintenance. Ultimately, selecting the appropriate valve type hinges on understanding the specific requirements of the application the nature of the fluid, pressure and temperature conditions, and the necessary flow control. Employing the right valve not only optimizes system performance but also extends the longevity of the infrastructure. Experts advocate for a meticulous evaluation of valve materials and design features to match the operational demands and ensure long-term reliability and safety. Integrating valves with advanced automation technologies can further enhance system efficiency. Smart valves equipped with sensors and IoT capabilities offer real-time monitoring and diagnostics, providing predictive maintenance insights that minimize downtime in critical operations. In conclusion, the expertise in selecting and maintaining the right valve types is invaluable. With a firm grasp on the varied functionalities and distinctive advantages of each valve type, businesses can achieve heightened operational efficiency and safeguard their systems against potential disruptions.

Needle valves provide precise control in low flow systems, thanks to their slender, tapered point at the end of the valve stem. Their ability to finely adjust flow rates makes them indispensable in applications where accuracy is crucial, such as fuel regulation in engines and flow metering in scientific instrumentation. Diaphragm valves utilize a flexible diaphragm to create a tight seal. This design is beneficial for corrosive or viscous fluids as it isolates the fluid from the moving mechanical components. Industries dealing with slurries or corrosive chemicals, such as mining and biopharmaceuticals, often employ diaphragm valves for their reliability and ease of maintenance. Ultimately, selecting the appropriate valve type hinges on understanding the specific requirements of the application the nature of the fluid, pressure and temperature conditions, and the necessary flow control. Employing the right valve not only optimizes system performance but also extends the longevity of the infrastructure. Experts advocate for a meticulous evaluation of valve materials and design features to match the operational demands and ensure long-term reliability and safety. Integrating valves with advanced automation technologies can further enhance system efficiency. Smart valves equipped with sensors and IoT capabilities offer real-time monitoring and diagnostics, providing predictive maintenance insights that minimize downtime in critical operations. In conclusion, the expertise in selecting and maintaining the right valve types is invaluable. With a firm grasp on the varied functionalities and distinctive advantages of each valve type, businesses can achieve heightened operational efficiency and safeguard their systems against potential disruptions.

Next:

Latest news

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

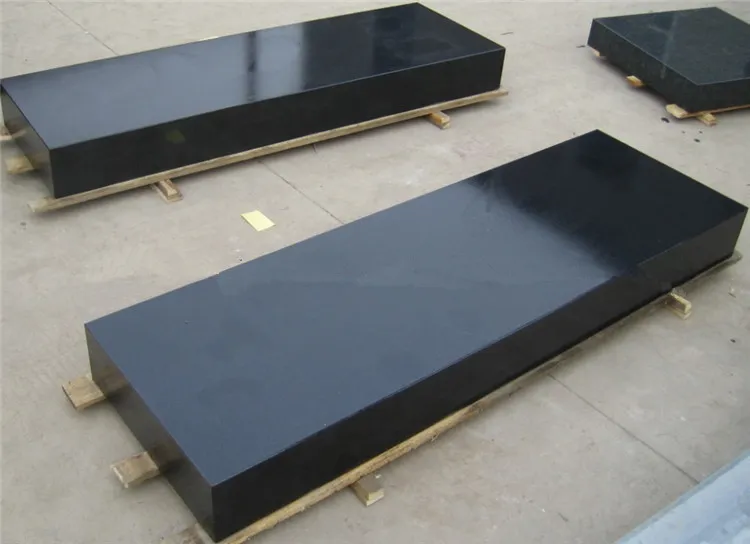

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS