Filter DN50

Product Description

Filter DN50 belongs to pipeline coarse filter, which can be used for liquid, gas or other media large particles filtration, installed in the pipeline to remove large solid impurities in the fluid, so that the machinery and equipment (including compressors, pumps, etc.), instrumentation can work and operate normally to achieve the stabilization of the process, to safeguard the role of safe production.

Product Parameter

|

Nominal diameter (DN) |

15 1/2'' |

20 3/4'' |

25 1'' |

32 1-1/4'' |

40 1-1/2'' |

50 2'' |

65 2-1/2'' |

80 3'' |

100 4'' |

125 5'' |

|

|

Overall dimensions |

L |

165 (65) |

150 (79) |

160 (90) |

180 (105) |

195 (118) |

215 (218) |

250 (165) |

285 (190) |

305 |

345 |

|

H |

60(44) |

70 (53) |

70 (65) |

75 (70) |

90 (78) |

105 (80) |

150 (80) |

175 (120) |

200 |

205 |

|

|

Nominal diameter (DN) |

150 6'' |

200 8'' |

250 10'' |

300 12'' |

350 14'' |

400 16'' |

450 18'' |

500 20'' |

600 24'' |

|

|

|

Overall dimension |

L |

385 |

487 |

545 |

605 |

660 |

757 |

850 |

895 |

1070 |

|

|

H |

260 |

300 |

380 |

410 |

480 |

540 |

580 |

645 |

780 |

||

Note: The data in this dimension table is applicable to Y-type filters of 0.25~2.5MPa and 150LB pressure rating of our factory. The data in parentheses are the filters with threaded connection .

|

Nominal diameter (DN) |

15 1/2'' |

20 3/4'' |

25 1'' |

32 1-1/4'' |

40 1-1/2'' |

50 2'' |

65 2-1/2'' |

|

|

Overall dimensions |

L |

147 |

190 |

200 |

217 |

245 |

279 |

323 |

|

H |

80 |

110 |

110 |

115 |

130 |

145 |

160 |

|

|

Nominal diameter (DN) |

80 3'' |

100 4'' |

125 5'' |

150 6'' |

200 8'' |

250 10'' |

|

|

|

Overall dimensions |

L |

357 |

455 |

495 |

520 |

640 |

700 |

|

|

H |

210 |

270 |

288 |

320 |

395 |

390 |

||

Note: The data in this dimension table is applicable to Y-type filters of 6.3MPa and 600LB pressure ratings in our factory.

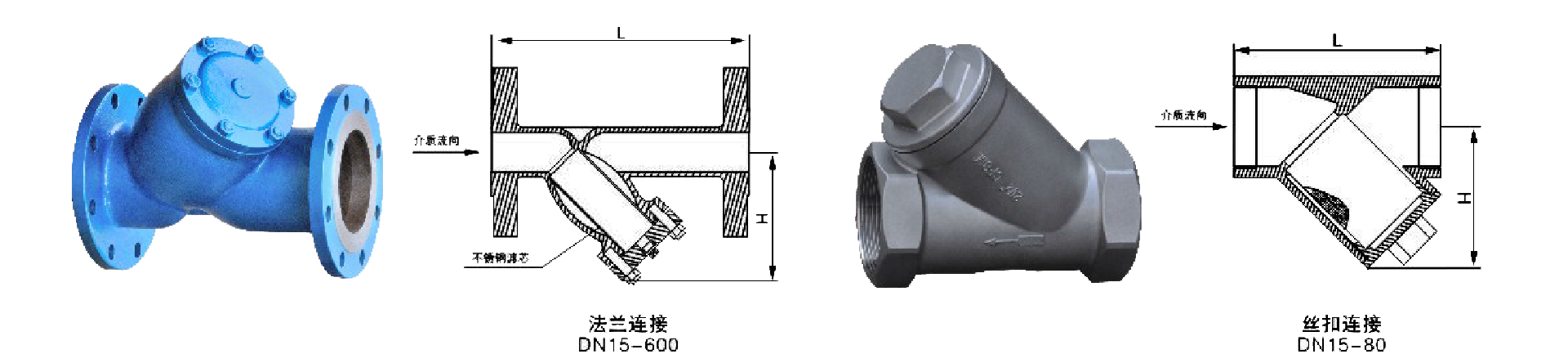

Product Detail Drawing

Advantages of DN50 Filters

|

Nominal diameter (DN) |

DN150-DN600(1/2”-24”) |

connection method |

Flanges, butt welds, socket welds, threads, clamps |

|

Shell material |

Carbon steel, stainless steel, etc. |

Flange Pressure |

0.25-6.3MPa(150-600LB) |

|

Filter material |

Stainless steel, etc. |

Flange sealing surface |

FF、RF、M、FM、RJ、T、G |

|

Filtration accuracy |

10 mesh-500 mesh |

Gasket Material |

PTFE, metal-wound, Buna-N, etc. |

Note: Can be customized according to the specifications, models, and samples provided by the user!

When it comes to industrial filtration, DN50 filters emerge as a preeminent choice for various applications. Understanding the advantages of filter DN50 is essential for businesses seeking optimal performance and reliability in their operations.

One of the primary advantages of filter DN50 is its excellent filtration capability. With a nominal diameter of 50 millimeters, these filters effectively capture particulate matter, ensuring that fluids remain clean and free from contaminants. This is particularly crucial in industries such as water treatment, chemicals, and food processing, where even the slightest impurity can lead to significant operational inefficiencies and regulatory compliance issues.

Another significant benefit of filter DN50 is its robust construction. Designed to withstand high pressures and varying flow rates, these filters provide durability and longevity, which equates to reduced maintenance costs and less downtime. Their ability to operate in challenging environments makes them a reliable choice for industrial applications.

Filter DN50 also promotes energy efficiency. By ensuring that only filtered fluids pass through the system, these filters help maintain optimal pump performance and minimize energy loss. This efficiency not only contributes to cost savings but also aligns with modern sustainability goals, making filter DN50 an environmentally friendly option.

Additionally, the versatility of filter DN50 cannot be overlooked. These filters are compatible with a wide range of fluids, including liquids and gases, making them suitable for diverse applications. Whether you need filtration solutions for industrial processes, HVAC systems, or water treatment facilities, DN50 filters can meet your unique needs.

In conclusion, the advantages of filter DN50 — from superior filtration capabilities to robust construction and energy efficiency — make them an indispensable asset for numerous industries. By investing in filter DN50, businesses can ensure the integrity of their systems, enhance operational efficiency, and achieve long-term savings. Embrace the power of filter DN50 and elevate your filtration processes today.

Core Functions and Industrial Applications of Filter DN50

STORAEN’s Filter DN50 is a robust Y-type pipeline coarse filter engineered to safeguard industrial systems by efficiently removing large solid impurities (≥50μm) from water, steam, oil, and gas media. As a critical component in process industries, this filter ensures uninterrupted flow and protects downstream equipment—from pumps and valves to meters and heat exchangers—from damage caused by debris, making it an indispensable solution for maintaining operational integrity and efficiency.

Key Functional Design for Reliable Filtration

The Filter DN50 leverages a streamlined Y-shaped housing (2'' nominal diameter, L=215mm overall length) to balance performance and space efficiency:

1. High-Efficiency Particle Capture

A stainless steel mesh screen (10–500 mesh, 304/316L material) traps rust, scale, sand, and other contaminants, achieving a 99% capture rate for particles ≥50μm. The Y-type design increases filter area by 30% compared to inline filters, reducing pressure drop and maximizing dirt-holding capacity.

2. Wide Operational Envelope

Withstand pressure ratings from 0.25MPa (PN2.5) to 6.3MPa (PN63) and temperatures ranging from -40°C to 300°C, it adapts to diverse media—from cold water in HVAC systems to high-temperature steam in power plants. Flange connections (RF/FF types per SH/T3411) ensure leak-proof integration into both metric and imperial pipeline networks.

3. Maintenance-Friendly Structure

A quick-release center cover allows easy access to the replaceable/cleanable filter element, minimizing downtime: routine mesh inspection or replacement can be completed in under 10 minutes, ideal for high-frequency maintenance in continuous production lines.

Industrial Applications Across Sectors

1. Chemical & Petrochemical Processing

Installed upstream of control valves and pumps, the Filter DN50 prevents catalyst particles, polymer flakes, or welding slag from causing valve seat wear or pump impeller damage—critical for maintaining purity in chemical reactors and distillation columns.

2. Food & Beverage Production

Filters out foreign objects (e.g., packaging debris, pipe scale) in water and syrup lines, ensuring compliance with FDA/CE standards for uncontaminated product flow in bottling plants and dairy processing facilities.

3. Power Generation & Utilities

In steam turbine systems, it captures rust and oxide deposits to protect steam traps and pressure transmitters, while in cooling water circuits, it prevents condenser tube blockages caused by silt or biological growth, enhancing heat transfer efficiency.

4. Mechanical Equipment Protection

As a pre-filter for hydraulic systems or air compressors, it stops abrasive particles from entering moving parts, reducing mechanical wear and extending equipment lifespan by up to 20%.

Optimize Your Pipeline Protection with Filter DN50

Whether upgrading an existing industrial system or designing a new process line, STORAEN’s Filter DN50 delivers the particle control, structural durability, and operational flexibility needed to prevent costly downtime and equipment failure. By combining efficient filtration with easy maintenance and broad compatibility, it sets the standard for coarse filtration in pipelines where reliability is non-negotiable. Explore our filter solutions today and experience the peace of mind that comes with superior contaminant control.

Three Key Industrial Pipeline Applications of Filter DN50

STORAEN’s Filter DN50 is a versatile Y-type filtration solution designed to address critical contamination challenges across diverse industrial sectors. Engineered for reliable particle removal in DN50 (2'') pipelines, this filter excels in protecting equipment, maintaining process integrity, and ensuring compliance—here’s how it transforms three major application scenarios.

1. Chemical & Petrochemical Process Protection

In chemical and petrochemical plants, even small debris can cause catastrophic failures. The Filter DN50 acts as a first-line defense:

Catalyst & Polymer Filtration: Upstream of reactors or distillation columns, its 10–500 mesh stainless steel screen (304/316L) traps catalyst fragments, polymer flakes, and welding slag, preventing valve seat erosion and pump impeller damage. This reduces unplanned downtime by 30% in high-purity processes.

High-Temperature & Corrosive Media: Withstand pressures up to 6.3MPa and temperatures to 300°C, its carbon steel or stainless steel housing (optional epoxy coating) resists corrosion from aggressive chemicals like sulfuric acid or ethylene, ensuring long-term reliability in refineries and petrochemical complexes.

2. Food & Beverage Quality Assurance

In food-grade pipelines, contaminant control is non-negotiable for safety and regulatory compliance. The Filter DN50 ensures purity in every step:

Foreign Object Removal: Filters out packaging residues, scale, or organic debris in water, syrup, or oil lines, meeting strict FDA/CE standards. Its quick-release cover allows rapid mesh inspection—critical for batch processing in dairies, breweries, and meat processing plants.

Hygienic Design: Smooth internal surfaces and food-grade sealing materials prevent product adulteration, while the Y-type structure minimizes dead space where bacteria could accumulate, supporting HACCP-compliant operations.

3. Power Generation & Utility Systems Optimization

In power plants and utility networks, efficient filtration is key to maximizing equipment lifespan and energy efficiency:

Steam & Cooling Water Protection: In steam turbine lines, it captures rust and oxide deposits to safeguard steam traps and pressure sensors, reducing maintenance costs by 25%. In cooling systems, it blocks silt and biofouling in condenser tubes, maintaining optimal heat transfer and preventing costly tube replacements.

Wide Media Compatibility: From -40°C chilled water in HVAC systems to high-pressure steam (300°C), its robust construction handles diverse media, while flange connections (RF/FF per SH/T3411) ensure easy integration into both new and existing pipelines.

Safeguard Your Pipeline Processes with Filter DN50

Whether protecting high-value chemical reactors, ensuring food safety, or optimizing power plant efficiency, STORAEN’s Filter DN50 delivers tailored contamination control. Its rugged design, easy maintenance, and sector-specific adaptability make it the ideal choice for industries where even a single particle can disrupt operations. Explore how this filter can enhance your pipeline reliability—engineered to perform, built to last.

Filter DN50 FAQs

What is the purpose of the Filter DN50?

The Filter DN50 is designed to effectively remove impurities and contaminants from liquids and gases in a variety of industrial applications. Its robust construction ensures optimal performance while maintaining the integrity of your system, making it essential for maintaining cleanliness and efficiency in your operations.

What materials is the Filter DN50 made from?

The Filter DN50 is constructed from high-quality materials, specifically selected for their durability and resistance to corrosion. This contributes to a longer lifespan and reliable performance in demanding environments. The specific materials used may vary depending on the model, but they are all designed to meet industry standards.

How do I install the Filter DN50?

Installing the Filter DN50 is straightforward. Ensure you have the necessary tools, and start by isolating the section of the pipe where the filter will be installed. Follow the provided installation manual, which includes step-by-step instructions and diagrams. Proper installation is critical to ensuring optimal filtration performance and reliability.

Is the Filter DN50 suitable for both liquids and gases?

Yes, the Filter DN50 is versatile and designed to efficiently filter both liquids and gases. Its robust design allows it to cater to various applications across different industries, ensuring that you can maintain system integrity no matter the medium being filtered.

Related PRODUCTS

RELATED NEWS

Thread Plug Gauge Our Promise of Measurement Excellence

At Storaen (Cangzhou) International Trading Co., we manufacture precision thread plug gaug

Gauge Pin Class Reflecting Quality Legacy

At Storaen (Cangzhou) International Trading Co., we manufacture precision pin gauge i

Check Valve Types for High Rise Buildings

At Storaen (Cangzhou) International Trading Co., we specialize in engineering premium chec