Jul . 31, 2024 06:13 Back to list

Understanding the Importance and Usage of Screw Thread Gauges in Precision Engineering

Understanding Screw Thread Gauges Essential Tools for Precision Engineering

Screw thread gauges are vital instruments in the field of precision engineering, ensuring that threaded components fit together seamlessly and function as intended. These gauges play a crucial role in the manufacturing and quality control processes of various industries, including automotive, aerospace, and machinery.

At its core, a screw thread gauge is designed to measure the dimensions and pitch of screw threads, which are spiral ridges that enable the fastening of components. The accuracy of these measurements is critical, as even the slightest deviation can lead to mechanical failures, issues with assembly, and potential safety hazards.

There are several types of screw thread gauges, each tailored for specific applications

. The most common types include pitch gauges, thread ring gauges, and thread plug gauges.Pitch Gauges are used to determine the pitch of a screw thread, which is the distance between consecutive threads. These gauges typically come as a series of blades, each marked with a specific pitch measurement. To use a pitch gauge, an engineer or technician aligns the gauge's teeth with the screw threads, allowing for an immediate assessment of whether the pitch falls within the required specifications.

Thread Ring Gauges are designed for measuring external threads. These gauges have a circular shape, enabling them to be threaded onto the part being assessed. The gauge will pass over the screw thread if the dimensions are correct. If the gauge does not fit, it indicates that the screw thread is either too large or too small, which can prevent proper assembly or compromise the integrity of the connection.

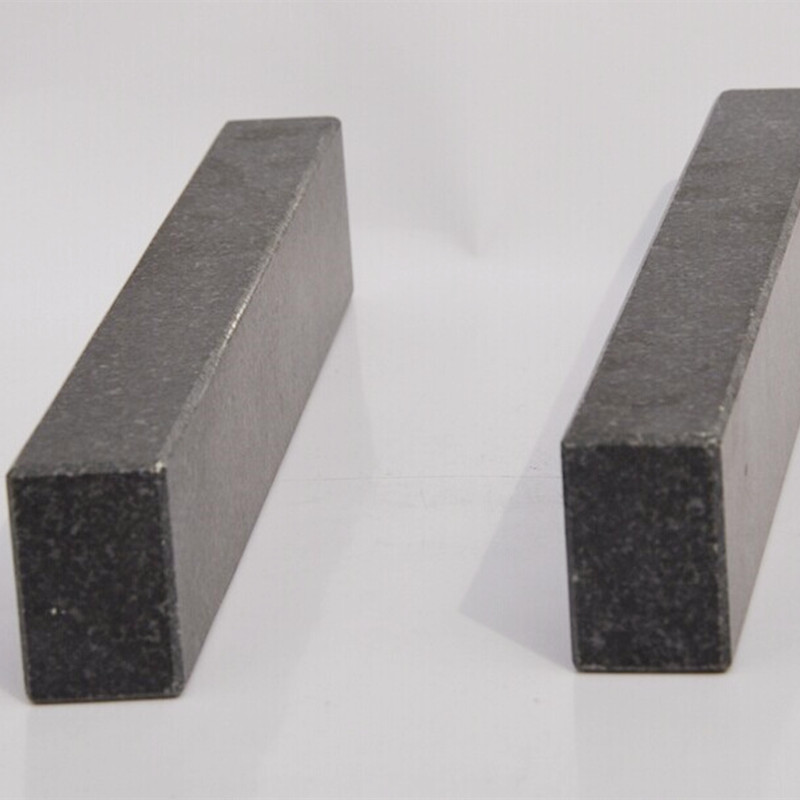

screw thread gauge

Thread Plug Gauges, on the other hand, are used for measuring internal threads. Similar to ring gauges but in a cylindrical form, these gauges are inserted into the threaded hole. A proper fit indicates that the internal dimensions are accurate, while a lack of fit signals the need for adjustment or further inspection.

The importance of screw thread gauges extends beyond mere measurements; they serve as a staple in ensuring consistency and quality in manufacturing processes. By utilizing these tools effectively, companies can minimize waste, reduce costs, and enhance overall product reliability.

In the realm of quality control, screw thread gauges are also integral to complying with industry standards. Various international standards exist, such as those set by the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI). These standards dictate the specifications for screw threads, and manufacturers must adhere to them to ensure product compatibility and safety.

With advancements in technology, screw thread gauging has evolved. Digital thread gauges have emerged, featuring electronic displays that offer precise measurements and eliminate human error associated with manual reading. Additionally, software solutions can record and analyze gauging data, providing manufacturers with valuable insights into their production processes.

In conclusion, screw thread gauges are indispensable tools in precision engineering. Their ability to accurately measure and assess screw threads ensures that components meet stringent industry standards, facilitating proper assembly and functionality. As technology continues to advance, the evolution of these gauges will likely enhance accuracy and efficiency, further solidifying their role in the manufacturing landscape. For engineers and manufacturers alike, understanding and properly utilizing screw thread gauges is key to achieving success in their respective fields.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS