Jul . 25, 2025 15:01 Back to list

Temperature and Pressure Limits for Common Butterfly Valve Types

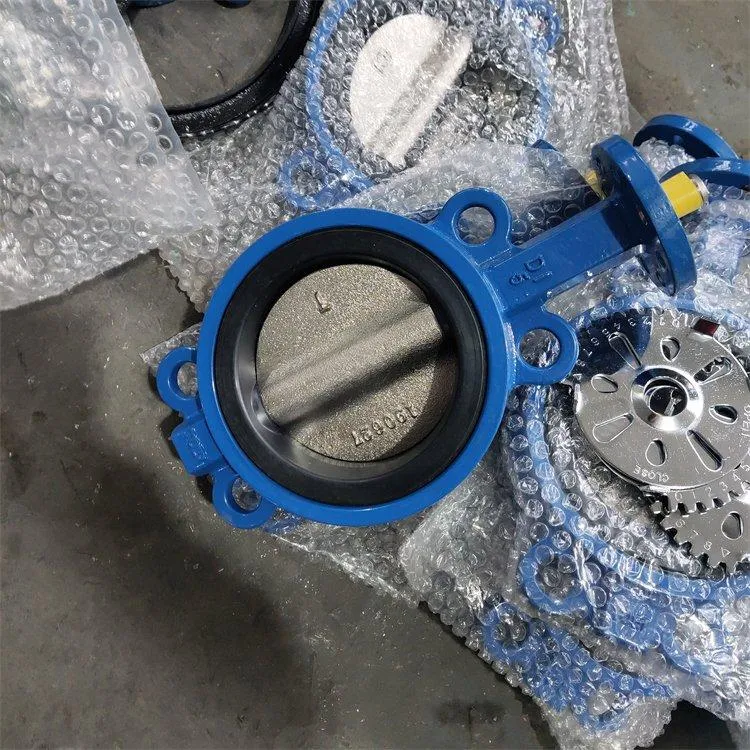

Butterfly valves are essential components in fluid control systems, offering efficient flow regulation in various industrial applications. Understanding the temperature and pressure limits of different butterfly valve types is crucial for optimal performance and safety. This article explores the capabilities of concentric, double-eccentric, and triple-eccentric butterfly valves for sale, helping wholesalers and engineers select the right valve for their systems.

Understanding Butterfly Valve Types and Their Design Differences

Butterfly valve types are categorized based on their disc alignment and sealing mechanisms. The three primary designs include:

Concentric (Resilient-Seat) Butterfly Valves

The disc rotates around a central axis with a soft (rubber or elastomer) seat.

Best for low-pressure, low-temperature applications like water distribution.

Double-Eccentric (High-Performance) Butterfly Valves

The disc is offset from the seat, reducing friction and wear.

Suitable for moderate pressures and temperatures in chemical and oil industries.

Triple-Eccentric (Metal-Seated) Butterfly Valves

Features an offset disc, conical seat, and inclined sealing surface for zero leakage.

Ideal for extreme conditions (high pressure, high temperature, corrosive media).

Each type has distinct temperature and pressure limits, impacting their butterfly valve types and applications.Understanding these differences is crucial when selecting the right butterfly valve for a specific application. For instance, concentric valves, with their resilient seats, offer an economic solution for general-purpose use where high performance is not a necessity. Double-eccentric valves, on the other hand, provide better sealing due to their design, making them suitable for more demanding applications that require frequent cycling or longer durability. Triple-eccentric valves, with their metal seats and advanced sealing mechanisms, are the go-to choice for severe service conditions, ensuring zero leakage and high reliability.Therefore, when considering butterfly valve types for installation, it's important to evaluate the operational requirements, including the expected pressure, temperature, and the nature of the media being controlled. Additionally, the cost-effectiveness and maintenance considerations should also be factored in. Some valve types may require more frequent maintenance or specialized handling, which can affect the overall life cycle cost.Furthermore, advancements in valve technology have led to the development of specialized butterfly valves tailored for specific industries. For example, valves designed for the food and beverage industry might incorporate materials that comply with hygiene standards and are resistant to cleaning agents. Similarly, valves for the cryogenic industry would need to withstand extremely low temperatures without compromising performance.In conclusion, selecting the appropriate butterfly valve type involves a thorough understanding of the application demands and the specific attributes each valve design offers. By matching the valve type to the operational requirements, one can ensure optimal performance, reliability, and efficiency in the process system.

Temperature and Pressure Ratings by Butterfly Valve Types

The following table compares key specifications for different butterfly valve types:

|

Valve Type |

Max Pressure (PSI) |

Temperature Range (°C) |

Best Applications |

|

Concentric (Soft Seat) |

150 PSI (PN10) |

-20°C to 120°C |

Water, HVAC, wastewater |

|

Double-Eccentric |

250 PSI (PN16) |

-30°C to 200°C |

Oil, gas, chemicals |

|

Triple-Eccentric |

600 PSI (PN40) |

-50°C to 600°C |

Steam, power plants, refineries |

Key Considerations:

Soft-seat valves (NBR, EPDM) degrade at high temperatures, limiting use in steam applications.

Metal-seated valves (stainless steel, Colonel) withstand extreme heat but require precise alignment.

Pressure drops occur faster in concentric valves due to disc obstruction.

Butterfly Valve Types and Their Impact on Performance

The butterfly valve handle types influence operation efficiency and durability:

Lever Handles

Manual operation for small valves (DN50 or below).

Limited to low-pressure systems (<150 PSI).

Gear Operators

Provide torque multiplication for larger valves (DN200+).

Suitable for medium-pressure applications (up to 250 PSI).

Actuated Valves (Pneumatic/Electric)

Automated control for high-pressure, high-temperature systems.

Used in triple-eccentric valves for critical shutoff.

Pro Tip: For high-temperature steam lines, gear-operated or actuated triple-eccentric butterfly valves ensure reliable sealing.

Industry-Specific Applications and Butterfly Valve Types Selection

Different butterfly valve types and applications require tailored solutions:

Water Treatment → Concentric valves (EPDM seats, 10-bar max).

Chemical Processing → Double-eccentric valves (Interlined, 16-bar max).

Power Plants → Triple-eccentric valves (metal seats, 40-bar steam resistance).

Oil & Gas → High-pressure double/triple-eccentric valves (API 609 certified).

Case Study: A refinery using triple-eccentric valves reduced maintenance costs by 40% due to superior wear resistance in high-temperature crude oil lines.

Butterfly Valve Types FAQs

What is the maximum temperature for a soft-seated butterfly valve types?

Soft-seated (concentric) valves typically handle up to 120°C, while EPDM seats may extend to 150°C. For higher temperatures, metal-seated valves are required.

Can butterfly valve types be used for high-pressure steam?

Yes, triple-eccentric butterfly valves with metal seats can withstand steam pressures up to 600 PSI (PN40) and temperatures exceeding 500°C.

Which butterfly valve types is best for corrosive chemicals?

Double-eccentric valves with PTFE or PFA lining offer excellent chemical resistance, handling acids and solvents at moderate pressures (up to 250 PSI).

How does a gear operator improve butterfly valve types performance?

Gear operators provide 5:1 torque multiplication, enabling smooth operation of large-diameter valves under high pressure, reducing seal wear.

Are butterfly valve types suitable for cryogenic applications?

Yes, specially designed triple-eccentric valves with extended stems and low-temperature seals operate down to -196°C (liquid nitrogen service).

For wholesalers and engineers seeking reliable butterfly valves for sale, our ISO-certified products offer:

Wide range of butterfly valve types (DN50–DN1200)

Custom materials & actuation options

Third-party tested for pressure & temperature compliance

Contact us today for bulk pricing and technical support—ensure your clients get the right valve for their system’s demands!

-

Heavy Duty Knife Gate Valve PerformanceNewsJul.25,2025

-

Choosing Between Gate and Globe Gate Valves for Optimal PerformanceNewsJul.25,2025

-

Cast Iron Y Strainer DurabilityNewsJul.25,2025

-

Ball Style Check Valve MaintenanceNewsJul.25,2025

-

Types of Strainer in Piping SystemsNewsJul.25,2025

-

The Role of Master Ring Gage in Quality Control SystemsNewsJul.25,2025

Related PRODUCTS