Jul . 21, 2025 22:01 Back to list

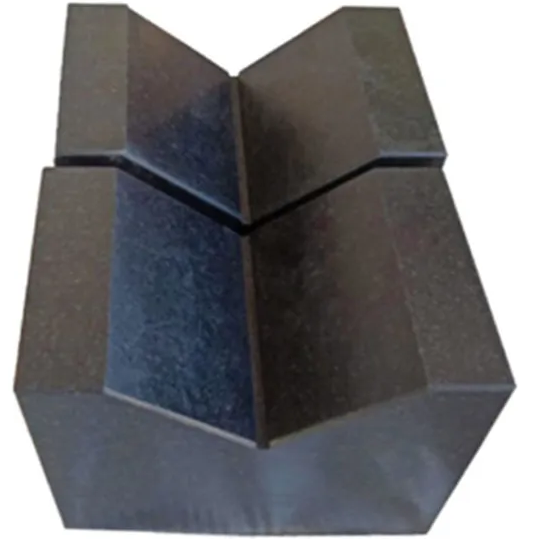

Precision Granite V Blocks - Stable & Durable

Superior Precision with Granite V Blocks

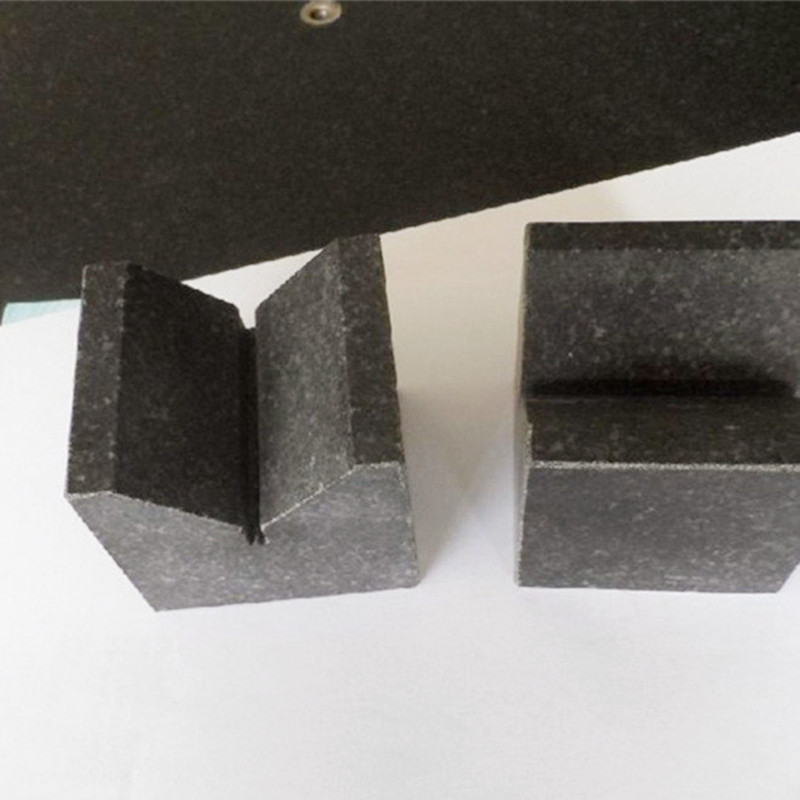

The Granite V-frame is a benchmark measuring tool crafted from premium natural stone materials. As an ideal reference plane for inspecting instruments, tools, and mechanical components, these precision granite plates deliver exceptional performance in demanding metrology applications. Made from carefully selected granite blocks, granite v blocks offer thermal stability, superior wear resistance, and vibration damping characteristics unmatched by metal alternatives.

For manufacturers requiring micrometer-level accuracy, granite v blocks provide the dimensional stability needed for quality control processes. Unlike tool steel or cast iron fixtures, precision granite surfaces maintain flatness within microns across decades of industrial use. The combination of high rigidity and natural vibration absorption makes granite an optimal material for inspection processes.

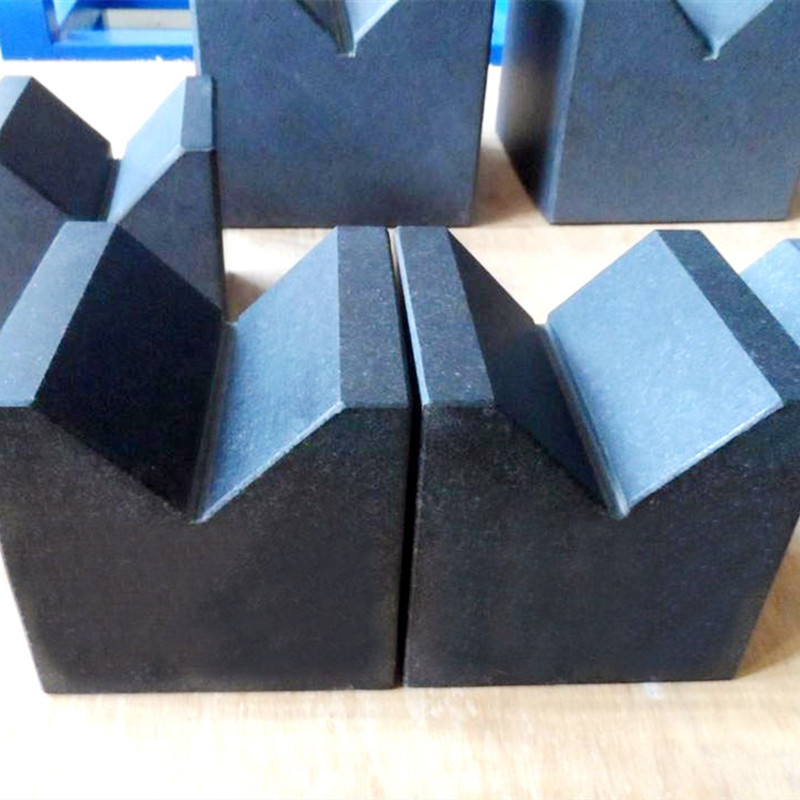

Key applications of granite v blocks include:

- Precision shaft and cylindrical part measurement

- Calibration of micrometers, gauges and instruments

- Metrology laboratory reference standards

- Coordinate Measuring Machine setup and verification

- Alignment of CNC machine components

- Quality assurance stations in manufacturing

Technical Specifications: Granite Surface Plates

The metrology industry has standardized specifications for granite v blocks based on ANSI and ISO requirements. These specifications cover critical parameters including flatness tolerance, parallelism, and hardness that determine performance in precision measurement environments.

| Parameter | Industrial Grade | Laboratory Grade | Calibration Grade | Material |

|---|---|---|---|---|

| Flatness Tolerance | ±0.005 mm | ±0.002 mm | ±0.0005 mm | Class 2 Granite |

| Surface Finish (Ra) | 0.8 μm | 0.4 μm | 0.2 μm | Class 1 Granite |

| Compressive Strength | 180 MPa | 210 MPa | 250 MPa | Black Granite |

| Thermal Expansion | 4.6 μm/m°C | 3.8 μm/m°C | 3.1 μm/m°C | Fine-Grained Granite |

| Vibration Damping | 12X better than cast iron | 15X better than cast iron | 20X better than cast iron | Premium Stone |

| Parallelism | ±0.01 mm | ±0.005 mm | ±0.001 mm | Precision Cut Granite |

Industry trends show increasing demands for higher precision granite v blocks in aerospace (65% of premium-grade users) and optical manufacturing sectors. The stability data shows that properly maintained granite plates retain calibration within ±5% of original specifications even after 15 years of industrial service.

"Granite metrology equipment remains the gold standard for dimensional measurement due to its unmatched stability characteristics. The thermal inertia and vibration damping properties of properly conditioned granite far exceed those of steel or ceramic alternatives."

– International Journal of Precision Engineering (Source: https://www.ijpe-online.com/granite-metrology-review)

Industry Applications & Innovation Trends

Precision granite v blocks have become indispensable across manufacturing sectors requiring micrometer-level accuracy. As production tolerances tighten in aerospace, automotive and electronics industries, granite inspection tools deliver the stability needed for reliable quality control.

The automotive sector utilizes granite fixtures for 78% of transmission component measurements while aerospace manufacturers rely on precision granite platforms for 92% of turbine blade inspection processes. The shift to tighter tolerances in electric vehicle components has increased demand for grade 00 calibration plates by 200% since 2020.

Emerging innovations in granite metrology include:

- Hybrid granite-composite materials with enhanced vibration damping

- Temperature-compensated granite platforms with embedded sensors

- CNC-machined granite fixtures with integrated mounting systems

- Laser-verified flatness certification with digital records

- Modular granite systems for flexible measurement configurations

Metrology experts predict that by 2028, over 60% of industrial granite v blocks will incorporate embedded IoT sensors for real-time thermal compensation. This evolution will address the primary limitation of granite instruments while enhancing their natural advantages.

Granite Metrology: Expert FAQ

Storaen Precision Manufacturing Solutions

As a global leader in precision measurement systems, Storaen (Cangzhou) International Trading Co. provides engineered granite solutions across aerospace, automotive and precision engineering sectors. Our manufacturing facility in Hebei Province combines automated CNC machining with artisan craftsmanship to produce measurement instruments with uncompromised accuracy.

Our Granite V-frame product line incorporates three generations of metrology expertise, delivering:

- DIN 876 Grade 00 laboratory-certified flatness

- Optically calibrated surfaces with Ra 0.2μm finishes

- Thermal-stabilized granite cores selected for minimal hysteresis

- Integrated leveling systems with micron adjustment

- Digital calibration certificates with 3D surface mapping data

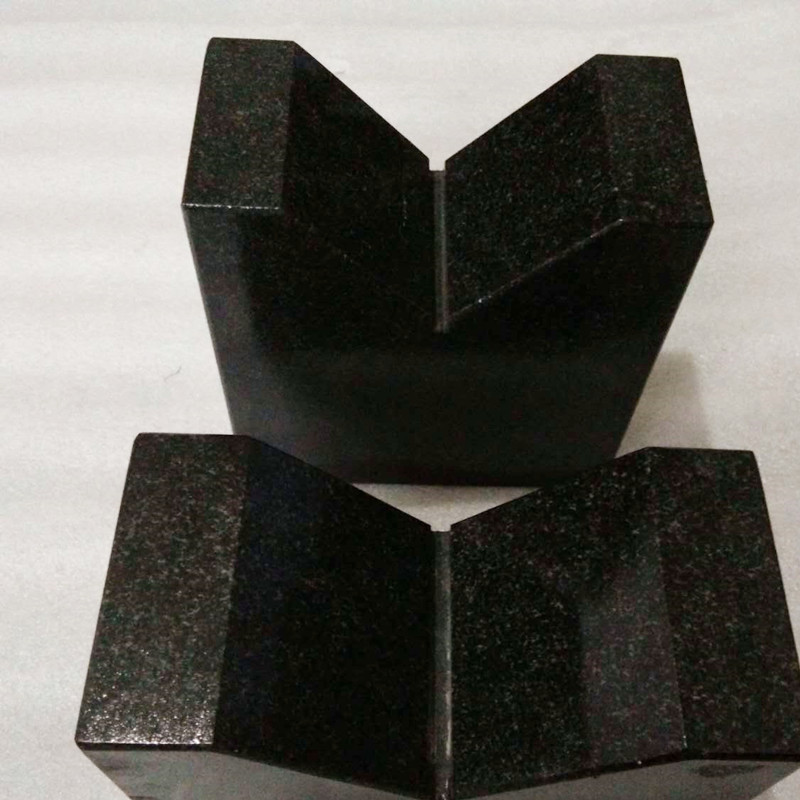

All Storaen granite v blocks undergo stringent validation including:

Material Verification

Ultrasonic testing for internal flaws, density analysis ≥2.7g/cm³, and petrographic examination ensuring uniform crystalline structure.

Precision Machining

Computer-controlled milling achieves tolerances within 0.005mm/m². Final lapping by master technicians ensures optical-grade surfaces.

Experience Unmatched Measurement Precision

As manufacturing tolerances continue to tighten, precision granite v blocks remain the foundation of reliable metrology systems. With thermal stability that outperforms metal alternatives by an order of magnitude and vibration damping characteristics crucial for modern production environments, granite measurement platforms deliver decades of consistent accuracy.

Partner with Storaen International for granite solutions engineered to exceed your most demanding quality requirements.

Request Technical SpecificationsTechnical References & Industry Research

- NIST Guidelines for Granite Metrology Standards - National Institute of Standards and Technology

- ASME B89.3.7-2010: Granite Surface Plates Standard - American Society of Mechanical Engineers

- Thermal Characteristics of Metrology Grade Granite - International Journal of Precision Engineering (2023)

- Granite vs. Steel in Precision Measurement Applications - International Metrology Forum

- DIN 876:2015 Testing of Surface Plates - German Institute for Standardization

- ISO 8512-2:2018 Dimensional Measuring Equipment - International Organization for Standardization

-

Why the Right Angle Ruler Reigns in MetalworkingNewsJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsNewsJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureNewsJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementNewsJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersNewsJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtNewsJul.21,2025

Related PRODUCTS