Comprehensive Guide to Surface Plate: Trends, Technology & Applications

The **surface plate**—renowned for its critical role in precision engineering and manufacturing—serves as the foundational reference for measurement, inspection, layout, and tooling setups. This article provides an in-depth exploration of **surface plate** types, industry trends, technology parameters, and highlights Storaen (Cangzhou) International Trading Co. as a trusted supplier in the global industrial landscape.

Enterprise Highlight: Your Reliable Partner

- Company: Storaen (Cangzhou) International Trading Co.

- Website: https://www.strmachinery.com

- E-mail: willGuo@strmachinery.com

- Phone: 19030670310

- Address:

No.17, Building 11, Hardware Building Material City,

Botou, Cangzhou City, Hebei Province, China

Storaen provides a complete portfolio of cast iron and granite surface plates, precision measuring tools, and customized industrial fixtures. With decades of experience and ISO-certified manufacturing standards, Storaen supports partners in automotive, aerospace, heavy equipment, and research.

Certifications: ISO 9001, ISO 17025

Global Export Footprint: 30+ countries

Global Export Footprint: 30+ countries

Industry Overview & Market Trends in Surface Plate Technology

The demand for high-precision **surface plate** solutions is steadily growing due to technological advancements and stringent quality standards across sectors. Automotive, aerospace, mechanical manufacturing, and laboratory research increasingly require robust measuring platforms such as iron surface plate and cast surface plate.

According to Eng-Tips Engineering Forum, “the evolution of material science and CNC manufacturing has elevated the functional accuracy required from surface plates—with a shift towards durability and traceable calibration.”

Common material choices include cast iron and granite, but cast iron surface plate remains preferred for its exceptional wear resistance, reparability, and economic value, offering attractive cast iron surface plate price points for both SMEs and large enterprises.

According to Eng-Tips Engineering Forum, “the evolution of material science and CNC manufacturing has elevated the functional accuracy required from surface plates—with a shift towards durability and traceable calibration.”

Common material choices include cast iron and granite, but cast iron surface plate remains preferred for its exceptional wear resistance, reparability, and economic value, offering attractive cast iron surface plate price points for both SMEs and large enterprises.

Technical Parameters: Surface Plate Comparison Table

| Type | Material | Flatness Accuracy | Surface Hardness (HB or HS) | Standard Sizes (mm) | Weight (kg) |

|---|---|---|---|---|---|

| Cast Iron Surface Plate | HT200-300 Cast Iron | Grade 0: ≤ 0.02 mm/m² Grade 1: ≤ 0.04 mm/m² |

160-220 HB | 300x300~3000x2000 | 20 - 5000 |

| Granite Surface Plate | Jinan Black/Granite | Grade 0: ≤ 0.013 mm/m² | 88-100 HS | 400x400~6000x3000 | 35 - 12000 |

| Steel Surface Plate | Tool steel | Grade 1: ≤ 0.06 mm/m² | 170-210 HB | 500x500~2000x1000 | 70 - 2200 |

| Ceramic Surface Plate | Alumina Ceramic | Grade 00: ≤ 0.009 mm/m² | 1100 HV | 200x200~1200x800 | 8 - 250 |

Surface Plate Technical Parameters Trend

Product Introduction: Cast Iron Angle Plates

Surface plate usage in inspections

Iron surface plate with V-slot

Cast surface plate for metrology

Heavy-duty cast iron surface plate

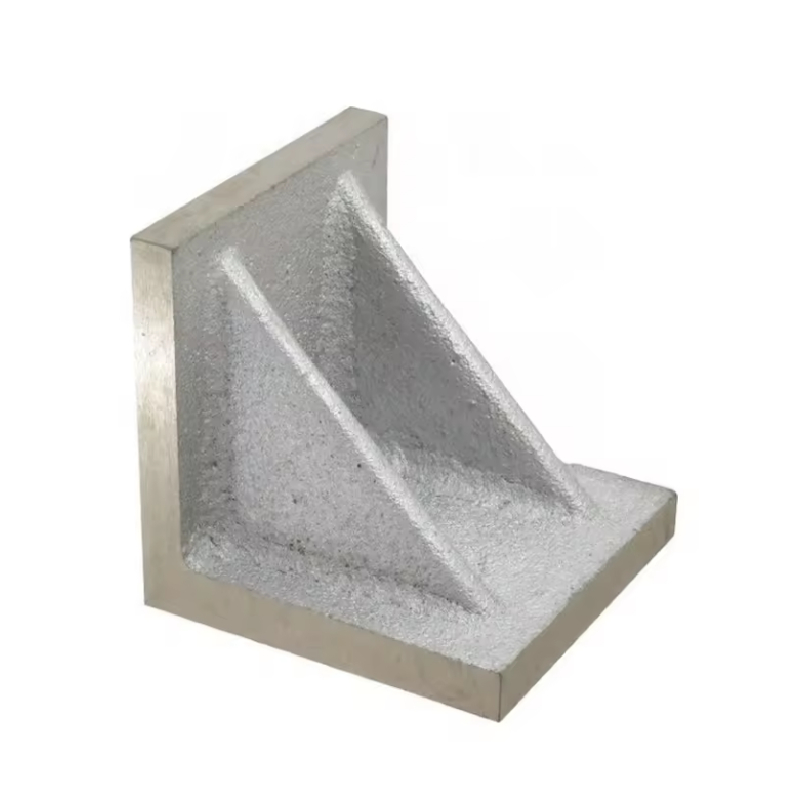

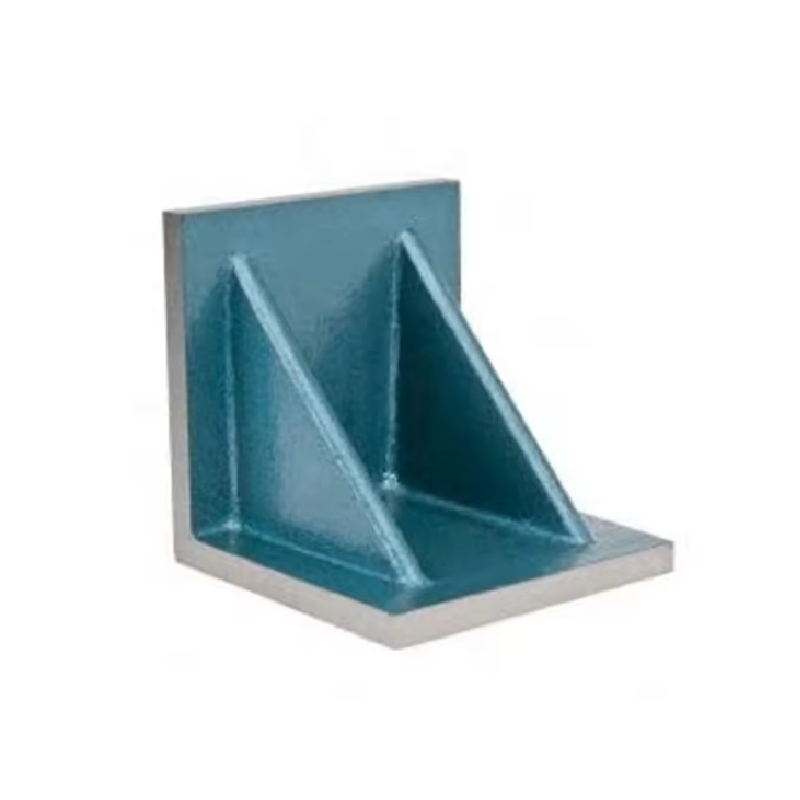

Product Name: Cast Iron Angle Plates

Description: Cast Iron Angle Plates are widely used for making fixtures as well as for checking squareness and parallelism of surfaces. All machined faces are square and parallel.

Recommended Application Scenarios:

Key Features:

Explore Cast Iron Angle Plates

Description: Cast Iron Angle Plates are widely used for making fixtures as well as for checking squareness and parallelism of surfaces. All machined faces are square and parallel.

Recommended Application Scenarios:

- Machinery assembly lines calibration

- Large-scale part inspection

- Tooling, fixture construction

- Automotive parts R&D

- Laboratory metrology setups

Key Features:

- High dimensional stability & excellent wear resistance

- Precision machined faces (flatness, squareness, parallelism)

- Easy for reconditioning and repair

- Cost-effective for high-accuracy needs (cheap surface plate)

- Customizable slots & mounting

Explore Cast Iron Angle Plates

Technical Indexes of Cast Iron Angle Plates: Visualization

| Specification | Unit | Value | Industry Standard |

|---|---|---|---|

| Material | - | HT200-300 Cast Iron | GB / DIN / ISO |

| Hardness | HB | 170-240 | ISO 1863-2019 |

| Surface Flatness | mm/1000mm | <= 0.025 | DIN 876 Grade 1 |

| Parallelism | mm | <= 0.05 | DIN 875 |

| Squareness | mm | <= 0.05 | DIN 875 |

| Usage Temperature | °C | -20~50 | - |

| Standard Size | mm | 160x100 to 500x4000 | Custom |

Hardness, Flatness & Parallelism

Component Material Pie

Flatness Index Variation

Surface Plate Industry Applications & Advantages

**Surface plates** underpin precision measurement in a vast range of tasks—from component layout, inspection, machine setup, calibration, and laboratory experiments. Key application sectors include:

- Metal Machining: Providing a stable datum for marking, machining, and measuring operations.

- Quality Control: Acting as a reference for dimensional inspection using CMMs, height gauges, and dial indicators.

- Fixture & Toolmaking: Creating robust setups for repeatable, accurate production.

- Automotive & Aerospace: Ideal for subassembly inspection, R&D, and component validation.

- Laboratory/Research: Essential base for experiments requiring micron-level accuracy.

- Unmatched flatness and stability

- Outstanding cost-effectiveness (cheap surface plate)

- Long working life and reparability (especially cast iron surface plate)

- Flexibility in customization and accessories

Professional Q&A: Surface Plate & Cast Iron Angle Plate Applications

1. What is the best material for a surface plate in industrial applications?

While granite and steel have their roles, cast iron surface plate is often preferred in heavy industry due to its excellent reparability, vibration-damping properties, and resistance to temperature changes.

2. How do you specify the flatness grade of a surface plate?

Flatness grades (e.g., Grade 0, Grade 1, Grade 2 per DIN 876) are defined by allowable deviation per square meter. For high-precision labs, Grade 0 (≤0.016mm/m2) is recommended.

3. What is the normal hardness range for cast iron surface plate?

Industry standards, such as ISO 1863-2019, specify a Brinell Hardness (HB) of 170–240 for cast iron surface plates, balancing wear resistance with machinability.

4. Are there international standards for surface plate production?

Yes. Main standards include DIN 876 (flatness), DIN 875 (squareness), ISO 8512, GB/T 22095, and ASME B89.3.7M. Adherence ensures universal compatibility and calibration traceability.

5. Why is squareness critical for angle plates?

Squareness guarantees that machined or inspected parts conform accurately to geometric tolerances, directly impacting final product quality in precision manufacturing.

6. How often should a surface plate be recalibrated?

For critical measurements, periodic recalibration (every 12-24 months, or as demanded by frequency of use/abrasion) is essential. Some applications require on-site inspection using electronic levelers as recommended by the NIST Metrology Guidelines.

7. What factors affect the cast iron surface plate price?

Price is influenced by size, flatness grade, weight, customization (T-slots, V-grooves), and certification/traceability requirements. Cheap surface plate models may offer basic accuracy, but industrial-grade plates invest more in precision and durability.

EEAT (Expertise, Authoritativeness, Trustworthiness): Meeting Industry Standards

- Expertise: Storaen’s engineers and QA staff regularly contribute to industry workshops and are certified by authoritative metrology bodies (ASME, International Society of Metrology).

- Authoritativeness: All products conform to DIN 876 and ISO standards, with test reports traceable to national laboratories.

- Trustworthiness: As reviewed by clients worldwide, Storaen upholds transparency in pricing (cast iron surface plate price), onsite technical support, and long-term service commitments.

Conclusion: Your Trusted Source for Surface Plate Solutions

Choosing the right surface plate is critical for precision engineering and measurement. With competitive cast iron surface plate price, strict adherence to standards, and expert technical support, Storaen (Cangzhou) International Trading Co. stands ready to supply the global market.

Further reading & reference:

Further reading & reference:

- Surface Plate Calibration & Accuracy Discussion (Eng-Tips Engineering Forums)

- Creep and Hardness Testing of Cast Iron Surface Plates (Rubber Chemistry and Technology Journal)

- NIST: Surface Plate Calibration Procedures

For project support, bulk pricing, or customization of surface plate and Cast Iron Angle Plates:

Contact Storaen: willGuo@strmachinery.com | surface plate product page.

Contact Storaen: willGuo@strmachinery.com | surface plate product page.