Jun . 25, 2024 07:29 Back to list

Magnetic V-Block 4 Inch Tool for Precision Machining and Alignment

Exploring the Utility of Magnetic V-Blocks A 4-Inch Solution for Precision Work

In the realm of precision engineering and manufacturing, the use of specialized tools is paramount to achieving the highest levels of accuracy and efficiency. Among these, magnetic V-blocks have carved a niche as indispensable workshop companions, particularly the 4-inch variant, which strikes a balance between versatility and manageability. This article delves into the features, applications, and benefits of the 4-inch magnetic V-block, underscoring its significance in various industries.

**Understanding Magnetic V-Blocks**

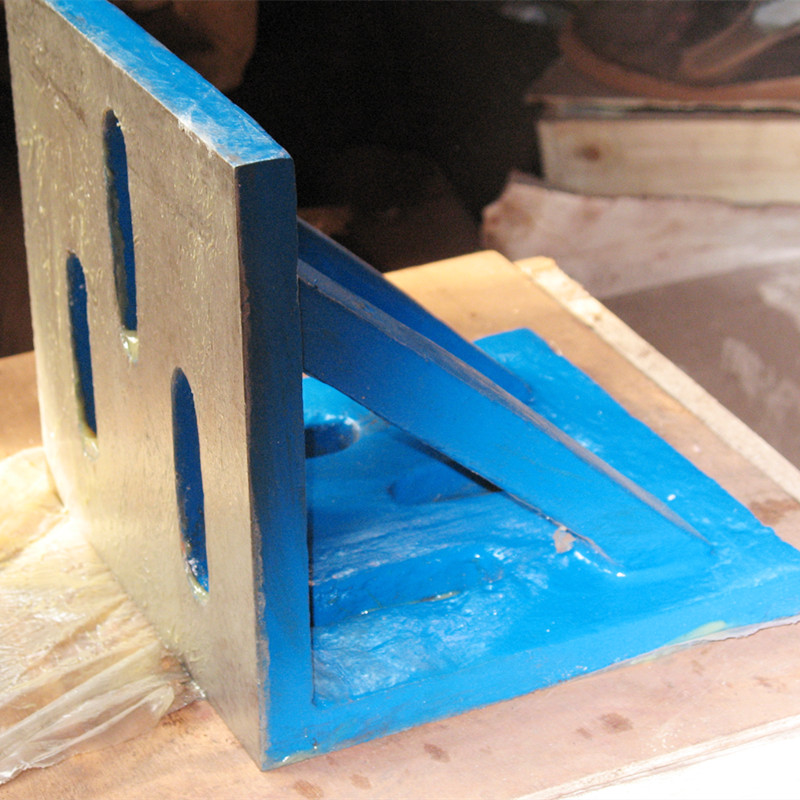

Magnetic V-blocks are precision-machined tools designed with two intersecting flat surfaces forming a 'V' shape. They are typically made from high-grade steel or iron, ensuring durability and resistance to wear. What sets them apart from traditional V-blocks is their magnetic base. This innovation allows for secure clamping onto ferromagnetic surfaces without the need for additional fixing devices, enhancing stability during machining, measurement, or inspection processes.

**The 4-Inch Magnetic V-Block A Versatile Choice**

Measuring 4 inches in length along the V-groove, this size is a popular choice due to its adaptability to a wide array of workpieces. It's small enough to handle intricate components like small engine parts, valves, shafts, and cylindrical objects, yet large enough to accommodate medium-sized pieces requiring meticulous alignment or support. The compact size also makes it easy to store and transport, a boon for mobile workshops or on-site repair services.

**Key Features & Benefits**

1. **Enhanced Clamping Stability** The magnetic base ensures a strong, even grip on metal surfaces, minimizing vibrations that could compromise measurement accuracy or machining quality. This feature is particularly valuable when working with delicate or precise operations where stability is crucial.

2. **Efficiency and Time-Saving** Traditional V-blocks require clamps or straps to secure them in place, adding setup time and complexity. Magnetic V-blocks eliminate these steps, allowing users to swiftly position and begin work, thereby streamlining workflows.

3

3 3

3

3

3 magnetic v block 4 inch. **Versatility in Application** From grinding and milling to inspection and assembly tasks, 4-inch magnetic V-blocks prove their worth across multiple stages of production. They can hold round, cylindrical, or irregularly shaped objects securely, making them indispensable in quality control departments for checking tolerances and straightness.

4. **Ease of Use and Adjustability** Users can easily reposition or rotate workpieces thanks to the quick-release mechanism of the magnetic force. This not only speeds up processes but also promotes flexibility in handling different types of jobs.

5. **Durability and Repeatability** High-quality magnetic V-blocks are built to withstand rigorous use and maintain their dimensional accuracy over time. This guarantees consistent results, contributing to overall process reliability.

**Applications Across Industries**

The 4-inch magnetic V-block finds extensive usage in automotive, aerospace, medical device manufacturing, and general engineering sectors. In the automotive industry, they facilitate the accurate machining and inspection of engine components. Aerospace manufacturers rely on them for the precise alignment of critical parts under strict tolerances. Medical device makers benefit from their precision during the delicate fabrication of surgical instruments and implants.

**Conclusion**

The 4-inch magnetic V-block stands as a testament to the ongoing evolution of precision tooling, marrying simplicity with advanced functionality. Its ability to enhance productivity, ensure accuracy, and facilitate ease of use across a broad spectrum of applications underscores its value as an essential tool in modern manufacturing and engineering environments. As technology advances and the demand for precision increases, magnetic V-blocks, especially those in versatile sizes like 4 inches, will undoubtedly continue to play a pivotal role in driving industrial efficiency and quality.

magnetic v block 4 inch. **Versatility in Application** From grinding and milling to inspection and assembly tasks, 4-inch magnetic V-blocks prove their worth across multiple stages of production. They can hold round, cylindrical, or irregularly shaped objects securely, making them indispensable in quality control departments for checking tolerances and straightness.

4. **Ease of Use and Adjustability** Users can easily reposition or rotate workpieces thanks to the quick-release mechanism of the magnetic force. This not only speeds up processes but also promotes flexibility in handling different types of jobs.

5. **Durability and Repeatability** High-quality magnetic V-blocks are built to withstand rigorous use and maintain their dimensional accuracy over time. This guarantees consistent results, contributing to overall process reliability.

**Applications Across Industries**

The 4-inch magnetic V-block finds extensive usage in automotive, aerospace, medical device manufacturing, and general engineering sectors. In the automotive industry, they facilitate the accurate machining and inspection of engine components. Aerospace manufacturers rely on them for the precise alignment of critical parts under strict tolerances. Medical device makers benefit from their precision during the delicate fabrication of surgical instruments and implants.

**Conclusion**

The 4-inch magnetic V-block stands as a testament to the ongoing evolution of precision tooling, marrying simplicity with advanced functionality. Its ability to enhance productivity, ensure accuracy, and facilitate ease of use across a broad spectrum of applications underscores its value as an essential tool in modern manufacturing and engineering environments. As technology advances and the demand for precision increases, magnetic V-blocks, especially those in versatile sizes like 4 inches, will undoubtedly continue to play a pivotal role in driving industrial efficiency and quality.

3

3

3

3 magnetic v block 4 inch. **Versatility in Application** From grinding and milling to inspection and assembly tasks, 4-inch magnetic V-blocks prove their worth across multiple stages of production. They can hold round, cylindrical, or irregularly shaped objects securely, making them indispensable in quality control departments for checking tolerances and straightness.

4. **Ease of Use and Adjustability** Users can easily reposition or rotate workpieces thanks to the quick-release mechanism of the magnetic force. This not only speeds up processes but also promotes flexibility in handling different types of jobs.

5. **Durability and Repeatability** High-quality magnetic V-blocks are built to withstand rigorous use and maintain their dimensional accuracy over time. This guarantees consistent results, contributing to overall process reliability.

**Applications Across Industries**

The 4-inch magnetic V-block finds extensive usage in automotive, aerospace, medical device manufacturing, and general engineering sectors. In the automotive industry, they facilitate the accurate machining and inspection of engine components. Aerospace manufacturers rely on them for the precise alignment of critical parts under strict tolerances. Medical device makers benefit from their precision during the delicate fabrication of surgical instruments and implants.

**Conclusion**

The 4-inch magnetic V-block stands as a testament to the ongoing evolution of precision tooling, marrying simplicity with advanced functionality. Its ability to enhance productivity, ensure accuracy, and facilitate ease of use across a broad spectrum of applications underscores its value as an essential tool in modern manufacturing and engineering environments. As technology advances and the demand for precision increases, magnetic V-blocks, especially those in versatile sizes like 4 inches, will undoubtedly continue to play a pivotal role in driving industrial efficiency and quality.

magnetic v block 4 inch. **Versatility in Application** From grinding and milling to inspection and assembly tasks, 4-inch magnetic V-blocks prove their worth across multiple stages of production. They can hold round, cylindrical, or irregularly shaped objects securely, making them indispensable in quality control departments for checking tolerances and straightness.

4. **Ease of Use and Adjustability** Users can easily reposition or rotate workpieces thanks to the quick-release mechanism of the magnetic force. This not only speeds up processes but also promotes flexibility in handling different types of jobs.

5. **Durability and Repeatability** High-quality magnetic V-blocks are built to withstand rigorous use and maintain their dimensional accuracy over time. This guarantees consistent results, contributing to overall process reliability.

**Applications Across Industries**

The 4-inch magnetic V-block finds extensive usage in automotive, aerospace, medical device manufacturing, and general engineering sectors. In the automotive industry, they facilitate the accurate machining and inspection of engine components. Aerospace manufacturers rely on them for the precise alignment of critical parts under strict tolerances. Medical device makers benefit from their precision during the delicate fabrication of surgical instruments and implants.

**Conclusion**

The 4-inch magnetic V-block stands as a testament to the ongoing evolution of precision tooling, marrying simplicity with advanced functionality. Its ability to enhance productivity, ensure accuracy, and facilitate ease of use across a broad spectrum of applications underscores its value as an essential tool in modern manufacturing and engineering environments. As technology advances and the demand for precision increases, magnetic V-blocks, especially those in versatile sizes like 4 inches, will undoubtedly continue to play a pivotal role in driving industrial efficiency and quality.

Latest news

-

Valves in Water Treatment PlantsNewsJul.07,2025

-

Safety Precautions When Installing Control ValvesNewsJul.07,2025

-

Importance of Routine Inspections for Ball Type Check ValvesNewsJul.07,2025

-

Function and Operation of 1 1 2 Gate ValvesNewsJul.07,2025

-

Enhancing the Performance of 1 1 2 Inch Check ValvesNewsJul.07,2025

-

DN50 Filter Water Valves in Municipal Water TreatmentNewsJul.07,2025

Related PRODUCTS