Jul . 23, 2025 02:01 Back to list

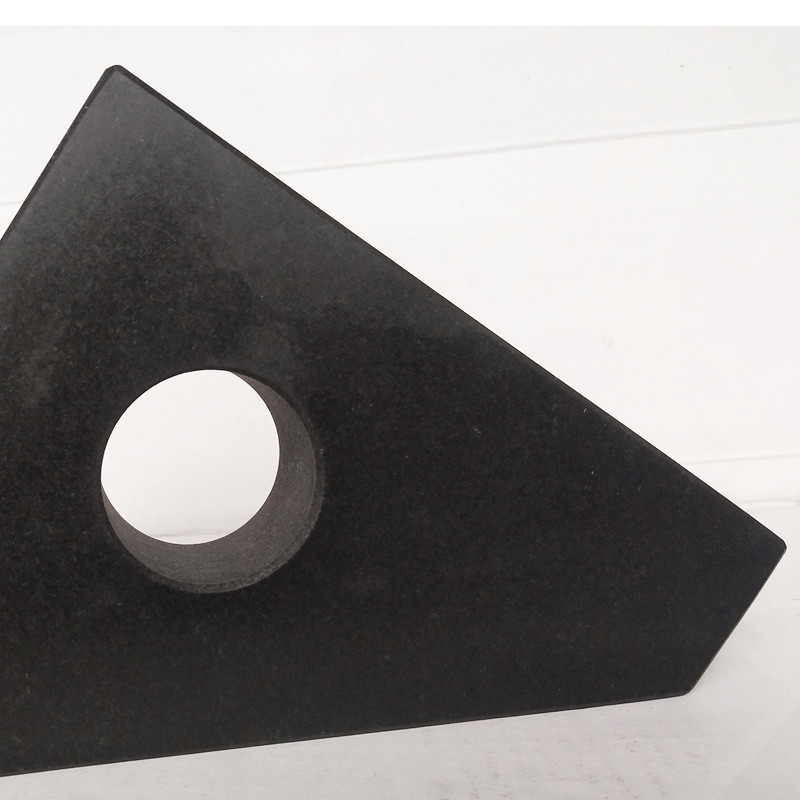

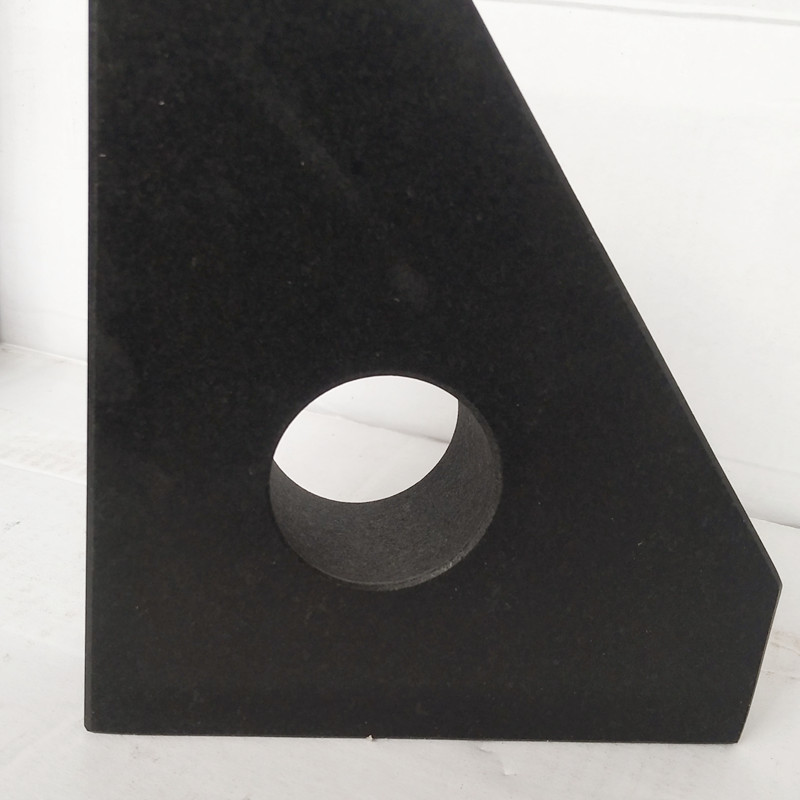

High Precision Granite Square Ruler for Inspection and Welding, 24 Inch Level

Trusted by industry experts and metrology professionals worldwide for precise, stable, and durable inspection of flatness and verticality.

Company Overview: Storaen (Cangzhou) International Trading Co.

Official Website: https://www.strmachinery.com

Product Page: Granite Square Ruler

Email: willGuo@strmachinery.com

Tel/Whatsapp: 19030670310

Address: No.17, Building 11, Hardware Building Material City,

Botou, Cangzhou City, Hebei Province, China

As a leading supplier and manufacturer in metrology and industrial measuring equipment, Storaen (Cangzhou) International Trading Co. has been recognized for its high standards regarding product precision, material selection, and global customer service. Over the last decade, Storaen has shaped the industry by integrating modern manufacturing techniques with classic material science.

What is a Granite Square Ruler?

The granite square ruler is a right-angle measuring tool engineered from premium granite, tailored for ultra-high precision verticality, flatness, and straightness inspection in industrial environments. Adhering to GB6092-85 plane accuracy and verticality standards, this inspection ruler features strategically placed weight reduction holes for easier handling without sacrificing strength or stability. Its main mineralogical components – plagioclase, olivine, biotite, and trace magnetite – deliver exceptional hardness, minimal thermal expansion, and long-term accuracy even under heavy-duty applications.

- Suitable for: Factory inspection, industrial laboratories, welding quality control, metrological institutes

- Main uses: Checking the flatness, verticality, and straightness of machine parts and assemblies

- Specification: Customizable dimensions, designed for various measurement & inspection needs (Special specifications available on request)

Industry Trends: Adoption of Granite Square Rulers in Modern Manufacturing

Global manufacturing and inspection sectors have witnessed a significant shift from traditional steel and cast iron rulers to granite square rulers due to their unmatched advantages in terms of dimensional stability, wear resistance, and low thermal expansion. According to the "Quality Magazine: Granite Surface in Metrology", the material’s long-term structural uniformity guarantees precise repeatability, making it indispensable for critical fields such as aerospace, automotive, and machine tool industry.

- Higher demand for inspection accuracy due to Industry 4.0 and automation integration

- Customization boom as sectors seek rulers for specialized inspection needs (e.g., 24 inch level with ruler)

- Increased investment in metrology labs: requiring reliable, rigid, and temperature-insensitive tools

Technical Specifications Table: Granite Square Ruler

| Feature | Specification |

|---|---|

| Material | Black granite (Plagioclase, olivine, biotite, magnetite) |

| Standard Compliance | GB6092-85 (Plane Accuracy & Verticality) |

| Tolerance (side) | 0.02 mm |

| Typical Sizes | 100x63mm, 200x125mm, 300x200mm, 500x315mm, 1000x630mm, customizable |

| Hardness (HS) | Above 70 |

| Linear Expansion | ~5 × 10-6 / ℃ |

| Weight Reduction Holes | Yes (for larger sizes) |

| Maintenance | Non-magnetic, corrosion-free, minimal care |

| Main Applications | Flatness, verticality, straightness inspection; welding inspection; CNC calibration |

| Customization | Available on request |

Comparison with Key Alternatives

| Granite Square Ruler | Steel Square Ruler | Cast Iron Inspection Ruler | |

|---|---|---|---|

| Stability | Extremely high, doesn't deform over time | Moderate, prone to warping/corrosion | Susceptible to environmental stress |

| Thermal Expansion | Very Low | Moderate | Moderate |

| Corrosion Resistance | Excellent | Poor, rusts easily | Moderate |

| Wear Resistance | Superior (Mohs ~6-7) | Good | Good |

| Magnetic Properties | Non-magnetic | Magnetic | Magnetic |

| Price | Moderate to High | Low | Moderate |

Granite Square Ruler in Industrial Applications

- Machined part inspection & quality audit (metrology labs, CNC workshops)

- Welding seam inspection and adjustment (welding inspection ruler)

- Tool and jig calibration (via level ruler and 24 inch level with ruler)

- Industrial training; geometric measurement for research institutes

- Laboratory measurement – meeting international and national standards for calibration

Thanks to their unrivaled performance, granite square rulers have become the backbone of critical inspection routines in precision machining shops and certified metrology laboratories.

Key Technical Indicators & Data Visualization

- Flatness Tolerance: Class 00 granite square rulers can reach ±0.002 mm/1000 mm

- Verticality Tolerance: Typically ≤0.005 mm for premium models

- Hardness: HS > 70 ensures superior scratch resistance and durability

- Granite density: ~2.97 g/cm3

- Thermal expansion: 5×10-6 per °C

Professional FAQ: Understanding Granite Square Rulers

- Q1: What materials are used for a granite square ruler?

- A1: Only select black granite, mainly comprised of plagioclase, olivine, biotite, and small amounts of magnetite. This ensures high hardness, structural stability, and minimal thermal expansion.

- Q2: What are the available standard and custom specifications?

- A2: Standard sizes range from 100x63mm to 1000x630mm, with custom dimensions available to meet specific inspection requirements for laboratories or factory floors.

- Q3: Which standards govern granite square ruler accuracy?

- A3: Production and inspection are based on GB6092-85 plane and verticality standards. This compliance ensures international acceptance for industrial measurement and certification.

- Q4: How is a granite square ruler maintained for zero deviation?

- A4: Due to natural non-corrosiveness and non-magnetic properties, the tool requires only occasional cleaning and should be stored in a temperature-stable environment to preserve accuracy for years.

- Q5: What distinguishes a level ruler or a welding inspection ruler from the granite version?

- A5: Granite square rulers offer superior wear resistance, stability, and accuracy. Level rulers, especially in a 24 inch level with ruler format, combine traditional levels with granite straightedge accuracy for specialized industrial work.

- Q6: How are weight reduction holes beneficial?

- A6: For larger granite rulers, designed weight relief holes reduce mass and enable easier handling while maintaining the tool’s integrity and measurement reliability.

- Q7: What is the long-term cost-benefit of granite over traditional materials?

- A7: Granite square rulers, though more expensive initially, last significantly longer, maintain accuracy, and require less recalibration, resulting in lower lifetime operating costs.

Further Resources & References

- Granite Metrology and Dimensional Stability: ResearchGate: Granite in Metrology

- Advanced Trends: ISO 8512-2: Inspection Rulers in International Standardization

- Industrial Application Forum: Practical Machinist: Granite Square vs. Steel Square

- Industry Review Article: Quality Magazine: Granite Surface Plates in Metrology

- Storaen (Cangzhou) International Trading Co.: Granite Square Ruler Product Page

Visit: No.17, Building 11, Hardware Building Material City, Botou, Cangzhou City, Hebei Province, China

This is the last article

-

Why the Right Angle Ruler Reigns in MetalworkingNewsJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsNewsJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureNewsJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementNewsJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersNewsJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtNewsJul.21,2025

Related PRODUCTS