Aug . 12, 2024 15:06 Back to list

Exploring the Features and Benefits of a 6-inch Butterfly Valve for Various Applications

Understanding the 6-Inch Butterfly Valve A Critical Component in Fluid Management

The butterfly valve is a vital component in many industrial applications, and the 6-inch butterfly valve is particularly popular due to its versatility and efficiency in regulating the flow of various fluids. As a quarter-turn valve, the butterfly valve utilizes a rotating disc to control flow, making it an ideal choice in scenarios where quick and reliable operation is paramount.

Design and Functionality

At its core, the 6-inch butterfly valve consists of several essential components the valve body, the disc, the stem, and the actuator. The valve body is typically constructed from materials such as cast iron, stainless steel, or plastic, depending on the application and fluid characteristics. The disc, which is mounted on a shaft, rotates within the flow path; when turned perpendicular to the flow, it effectively blocks the passage, while a parallel position allows for free movement of the fluid.

The simplicity of the design lends itself to easy installation and maintenance. The compact nature of butterfly valves enables them to fit into tight spaces, making them suitable for a wide range of industrial applications including water treatment, HVAC systems, and process industries.

Operational Advantages

One of the most significant advantages of a 6-inch butterfly valve is its ability to provide quick and efficient flow control. The quarter-turn operation means that the valve can be opened or closed with minimal effort and time, which is critical in emergency scenarios where immediate action is required. Additionally, the linear flow characteristics of a butterfly valve provide excellent throttling capabilities, allowing operators to adjust flow rates with precision.

6 inch butterfly valve

Another important aspect of the butterfly valve is its lightweight design. Compared to other valve types, such as gate or globe valves, the butterfly valve can significantly reduce the overall weight of a piping system, leading to lower installation and support costs. This weight advantage is especially beneficial in applications involving large-diameter pipes or elevated installations.

Applications

6-inch butterfly valves find their place in numerous industries. In water and wastewater treatment plants, they help manage the flow of water efficiently while minimizing pressure loss. In chemical processing, they are used to control the flow of corrosive substances, particularly when constructed from resistant materials like PVC or stainless steel. The HVAC industry also utilizes butterfly valves to manage airflow in ducting systems, providing energy efficiency and precise climate control.

Considerations for Selection

When selecting a 6-inch butterfly valve, several factors should be considered to ensure optimal performance. These include the type of fluid being managed, temperature and pressure conditions, and the specific application requirements. Material selection is also crucial; for instance, using a valve made from stainless steel might be necessary for applications involving high temperatures or corrosive fluids. Furthermore, the type of actuator—manual, electric, or pneumatic—should align with the operational demands of the system.

Conclusion

In conclusion, the 6-inch butterfly valve is an indispensable tool in modern fluid management across various industries. Its design simplicity, operational efficiency, and adaptability make it a preferred choice for engineers and operators aiming for reliable fluid control. By understanding the capabilities and applications of butterfly valves, professionals can make informed decisions that contribute to the safety and efficiency of their systems while addressing the ever-changing demands of industrial processes. As technology continues to advance, the role of the butterfly valve will likely evolve, driven by the need for sustainability and enhanced performance in fluid management systems.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

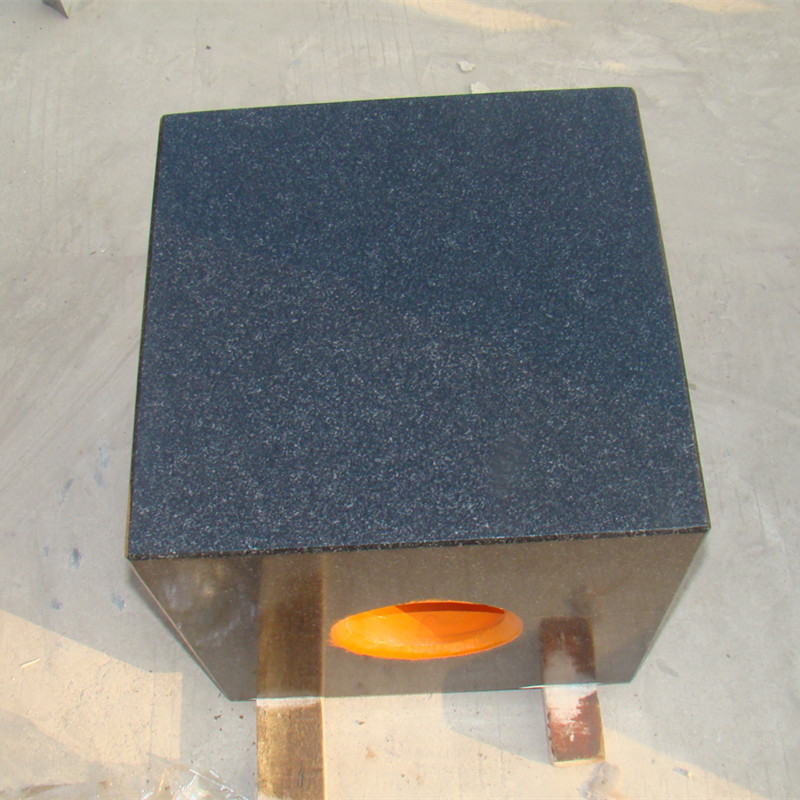

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS