Aug . 12, 2024 15:30 Back to list

Exploring the Features and Benefits of 36 Percent Butterfly Valve Models in Today's Industry

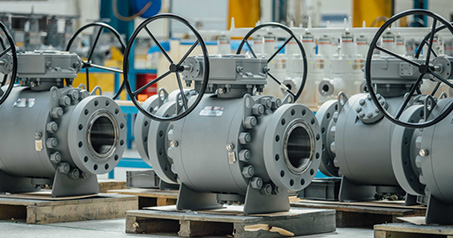

Understanding the 36% Butterfly Valve An Essential Component in Fluid Control

The butterfly valve is a pivotal component in the world of fluid control, known for its simplicity, reliability, and efficiency in regulating the flow of liquids and gases. Among the various types of butterfly valves, the 36% butterfly valve is particularly noteworthy due to its unique design and functionality. This article delves into the specifics of the 36% butterfly valve, its applications, advantages, and considerations for use.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn valve that comprises a rotating disc or butterfly mounted on a shaft. This disc pivots to open or close the valve, allowing or obstructing the flow of fluid. Typically employed in piping systems, these valves are favored for their compact structure and minimal spatial requirements compared to other valve types.

The 36% Butterfly Valve Design

The term 36% butterfly valve usually refers to the specific design characteristics and operational capabilities of the valve. The designation could denote the amount of disc area that is effective in controlling flow, which influences the valve's performance in various applications. The functionality of a 36% butterfly valve is honed for particular environments, making it ideal for certain industry needs.

The 36% butterfly valve operates under the principle of pressure differential, utilizing design features that allow it to maintain a stable flow rate while minimizing energy loss. Its construction typically includes robust materials designed to withstand corrosive substances, high pressures, and extreme temperatures. This makes it an excellent choice for demanding applications across various sectors.

Applications in Industry

Butterfly valves, including the 36% variant, find extensive use in many industries, such as

1. Water Treatment Facilities They are crucial for regulating water flow, whether in municipal water supply systems or wastewater treatment plants. Their ability to provide tight sealing helps in maintaining optimal flow rates and preventing contamination.

36 butterfly valve

2. Chemical Processing In the chemical industry, the 36% butterfly valve is often utilized for controlling the flow of corrosive materials. Its robust materials and construction help mitigate risks associated with aggressive chemicals.

3. HVAC Systems Within heating, ventilation, and air conditioning systems, these valves are instrumental in balancing air flow, thereby maximizing energy efficiency and maintaining desired temperatures.

4. Food and Beverage Industry Here, cleanliness and hygiene are paramount. The 36% butterfly valve's design facilitates easy cleaning and maintenance, making it suitable for controlling flow in applications such as brewing and beverage dispensing.

Advantages of the 36% Butterfly Valve

One of the primary advantages of the 36% butterfly valve is its space-saving design. Its compact nature allows for installation in areas where space is a premium. Additionally, the quick and easy operation afforded by the quarter-turn mechanism enhances efficiency in fluid control.

Another advantage is the cost-effectiveness of butterfly valves. They generally require less material and energy to manufacture than other valve types while providing comparable performance. This, combined with their low maintenance requirements, translates to reduced operational costs over time.

Considerations for Use

While the 36% butterfly valve provides numerous benefits, users must consider certain factors. Proper sizing is critical, as an incorrectly sized valve can lead to inefficiencies and increased wear and tear. It’s also essential to evaluate the compatibility of the valve materials with the specific fluids being controlled to prevent degradation.

In conclusion, the 36% butterfly valve serves as a fundamental piece in fluid control mechanisms across various industries. Its unique design, efficiency, and reliability make it an invaluable tool for engineers and operators alike. Understanding its features and applications allows for informed decision-making, ensuring optimal performance in fluid management systems.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS