Aug . 13, 2024 09:16 Back to list

Exploring the Benefits and Applications of Digital Snap Gauges in Precision Measurement Tasks

Understanding Digital Snap Gauges Precision Measurement for Modern Industries

In today's fast-paced industrial landscape, precision is paramount. As manufacturers strive to enhance quality control and ensure product consistency, tools that support accurate measurements become indispensable. Among these tools, digital snap gauges stand out as vital instruments in various fields, from manufacturing to quality assurance.

Digital snap gauges are specialized measuring devices designed to accurately determine the dimensions of various components, particularly the thickness and diameter of materials. Unlike traditional mechanical gauges, which rely on manual readings and analog scales, digital snap gauges utilize electronic sensors to provide instantaneous and precise measurements displayed on a digital screen. This advancement significantly reduces human error, enhances repeatability, and facilitates quicker decision-making in production settings.

The operation of a digital snap gauge is straightforward. When measuring a part, the operator places the component between the two measuring jaws of the gauge. Once the jaws are closed, the device's sensors detect the distance between them and display this measurement digitally. Most modern gauges feature high-resolution readouts, often down to microns, and can toggle between different measurement units (such as millimeters and inches) at the push of a button. Furthermore, many digital snap gauges incorporate data logging capabilities, allowing users to track measurements over time for further analysis and quality assurance.

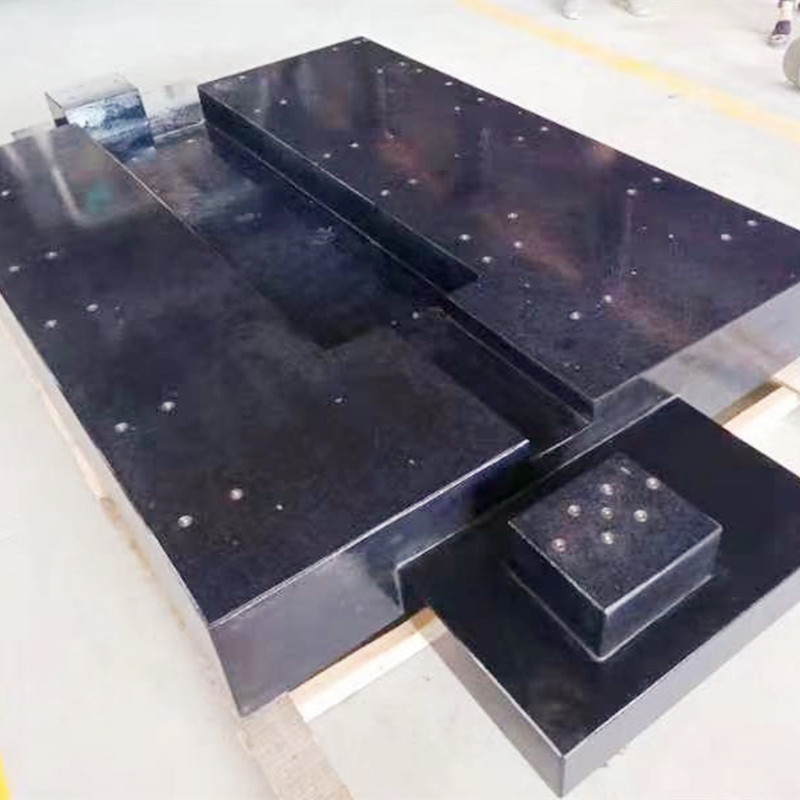

digital snap gauge

One of the primary advantages of digital snap gauges is their versatility. They can be used in various applications, including automotive, aerospace, electronics, and textiles. For instance, in the automotive industry, snap gauges are crucial for measuring the thickness of materials used in manufacturing components such as body panels and engine parts. In electronics, they ensure that components meet specified tolerances, which is critical for device functionality and reliability.

The accuracy of digital snap gauges makes them particularly useful for quality control processes. Manufacturers can easily establish specified tolerances for their products, and digital snap gauges provide the means to verify that these tolerances are consistently met. This capability leads to reduced waste, fewer returns, and enhanced customer satisfaction. In industries where compliance with stringent regulations is essential, such as medical device manufacturing, the use of precise measurement tools is not just beneficial but often mandatory.

Moreover, the advancement in technology has made digital snap gauges more accessible and user-friendly. Most models are designed with ergonomics in mind, featuring easy-to-read displays, intuitive interfaces, and lightweight constructions, making them convenient for operators of all experience levels. Some high-end models even come with wireless connectivity options, allowing them to interface with computer systems for real-time data reporting and analysis.

In conclusion, digital snap gauges represent a significant leap forward in measurement technology. Their precision, ease of use, and versatility make them invaluable tools across various industries. As the demand for high-quality products continues to rise, the role of such measurement devices will undoubtedly become more critical. By incorporating digital snap gauges into their measurement processes, manufacturers can enhance their quality control measures, drive efficiency, and ultimately deliver superior products to the market. Embracing this technology is not merely an option but a necessity for those who aim to stay competitive in today's demanding industrial environment.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS