Aug . 13, 2024 09:18 Back to list

Creating an Accurate Measurement System with a Comprehensive Micrometer Set for Precision Tasks

Understanding the Micrometer Set A Precision Tool for Measurement

In the world of precision engineering and manufacturing, accurate measurements are crucial. Among the various tools employed, the micrometer set stands out as an essential instrument for professionals and enthusiasts alike. Designed to measure small distances with high accuracy, micrometers have become indispensable in industries such as machining, manufacturing, and scientific research.

A micrometer is a mechanical device that employs a calibrated screw to measure small distances, generally in the range of a thousandth of an inch (0.001 in) or a hundredth of a millimeter (0.01 mm). The typical micrometer consists of a U-shaped frame, an adjustable spindle, and a thimble that rotates around a central axis. The principle behind its operation is based on the screw's thread, which allows for fine adjustments and high precision measurement.

Micrometers come in various types, each designed for specific applications. The most common is the outside micrometer, used for measuring the outside dimensions of an object, like the diameter of a shaft. Inside micrometers, on the other hand, are designed to measure internal dimensions such as the diameter of holes. Depth micrometers measure the depth of grooves or holes. Each type of micrometer set may include different measurement ranges and increments, allowing users to select the right tool for their specific needs.

One of the significant advantages of using a micrometer set is its ability to provide precise measurements. A well-calibrated micrometer can achieve an accuracy within ±0.001 inches or ±0.01 millimeters. This level of precision is essential in fields like manufacturing, where even the smallest deviation can lead to inefficiencies, product failures, or safety hazards.

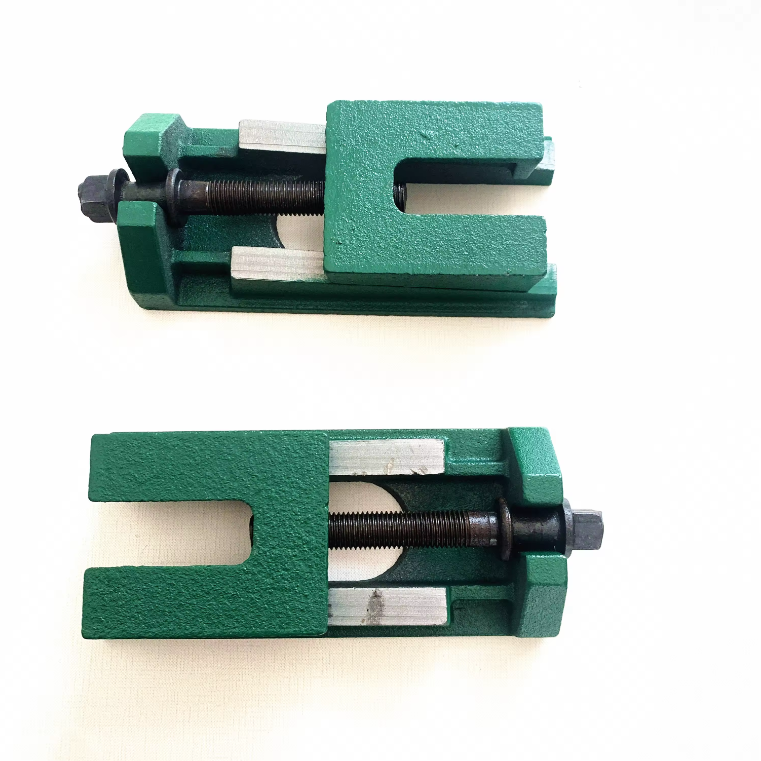

micrometer set

When using a micrometer, proper technique is critical. The user must gently close the micrometer’s spindle against the object being measured. This should be done with a consistent pressure— typically achieved by turning the thimble until a slight resistance is felt. Many micrometers are equipped with a ratchet mechanism that prevents over-tightening, which could damage both the tool and the workpiece. Calibration is also vital to ensure the micrometer provides accurate readings. Regular checks against known standards can help maintain the tool’s accuracy over time.

Micrometer sets often come packaged in protective cases for storage and transport. Many manufacturers also provide calibration tools and instructions to help users maintain their tools properly. When purchasing a micrometer set, it’s essential to choose a high-quality brand, as the durability and accuracy of the tool will significantly impact its performance.

As industries and technologies advance, the use of micrometers is evolving as well. Digital micrometers, for instance, have emerged as an option that combines traditional mechanical measurement with electronic displays. These tools can provide instant readings, memory functions, and even data output to computers, enhancing the measurement experience and improving efficiency.

In conclusion, the micrometer set is an invaluable tool that plays a critical role in precision measurement across various industries. Its ability to measure small distances with exceptional accuracy makes it essential for ensuring quality in manufacturing and engineering. Understanding how to properly use and maintain a micrometer set not only enhances measurement accuracy but also contributes to the overall efficiency and integrity of production processes. For anyone involved in precision work, investing in a high-quality micrometer set is a decision that pays dividends in accuracy and reliability.

-

Right Angle Ruler Innovations in Measuring ToolsNewsJul.18,2025

-

Parallel Ruler Maintenance for Long-Term AccuracyNewsJul.18,2025

-

Magnetic V Block 4 Inch Cost Effectiveness AnalysisNewsJul.18,2025

-

Internal Thread Gauge Innovations for Faster InspectionNewsJul.18,2025

-

Ground Anchor Applications in Construction and LandscapingNewsJul.18,2025

-

Butterfly Valve Types StandardsNewsJul.18,2025

Related PRODUCTS