Aug . 21, 2024 21:41 Back to list

Building a Custom Welding Table for Your Workshop Needs

Making a Welding Table An Essential Guide

Creating a welding table is a fundamental task for anyone involved in metalworking, whether you're a professional welder or a DIY enthusiast. A sturdy, well-designed welding table can significantly improve your welding experience, enhance the quality of your work, and ensure safety during the process. In this article, we’ll delve into the importance of a welding table, its essential features, and step-by-step instructions to help you create your own.

Why a Welding Table is Important

A welding table serves several critical purposes. First and foremost, it provides a stable and secure surface for your work. Welding involves high heat, sparks, and molten metal, making it essential to have a table that can withstand these stresses without warping or catching fire. Furthermore, a well-crafted table allows for precise manipulation of your materials, leading to better welds and improved overall project quality.

Additionally, a welding table often has various features that enhance functionality, such as built-in clamping systems, adjustable height settings, and integrated fixtures for holding materials securely in place. These features can broaden your range of capabilities and allow for more complex projects.

Essential Features of a Good Welding Table

When designing your welding table, consider the following features

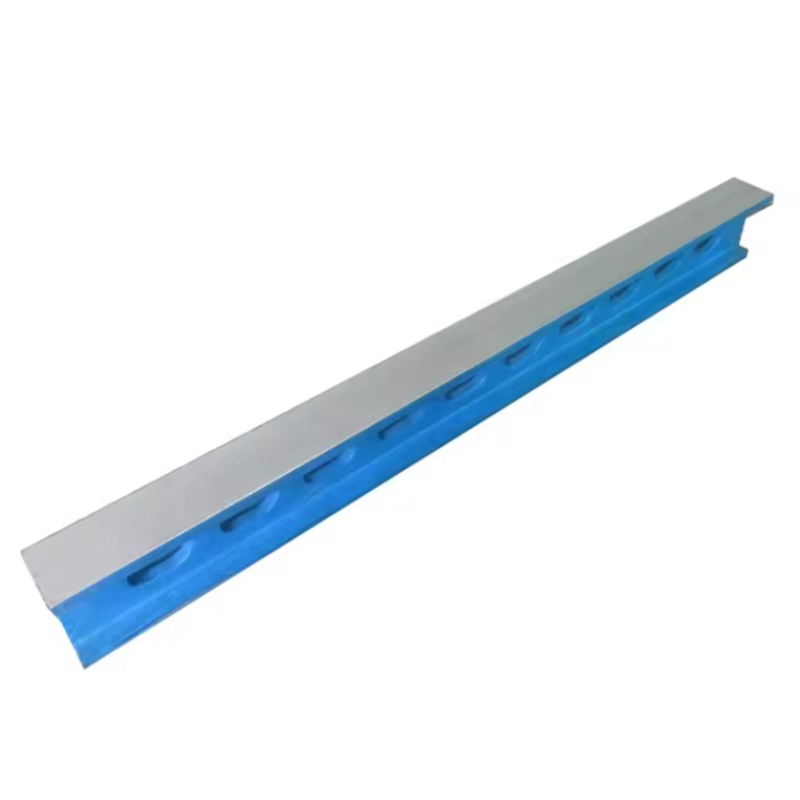

1. Material The table should be constructed from durable materials such as steel or heavy-duty aluminum. Steel is popular due to its strength and ability to handle heat. A thick top (at least 3/16 inch) is recommended to minimize warping.

2. Flat Surface A flat surface is crucial for accurate and consistent welding. You can achieve this by using a precision-ground plate or heavy-duty plywood with a steel top.

3. Clamping Systems Integrated clamping systems make securing workpieces easier. Consider incorporating T-slots or C-clamps into your design for added versatility.

4. Mobility Depending on your workshop space, you may want a welding table that can be easily moved. Adding wheels can enhance portability without sacrificing stability.

making a welding table

Step-by-Step Instructions to Build Your Welding Table

Materials Needed

- Steel plates or heavy-duty plywood - Steel tubing for the frame - Welding equipment - Clamps and screws - Wheels (if desired) - Paint or coating for protection against rust

Instructions

1. Design Your Table Determine the size and shape of your table based on your projects and workspace. A typical size is around 3x5 feet, with a height of about 34 inches.

2. Build the Frame Using steel tubing, construct a robust frame. Weld the corners and ensure it’s square. This structure should support the weight of the tabletop and maintain stability.

3. Attach the Top Securely attach your chosen tabletop material to the frame. If using steel plates, weld them in place, ensuring there are no gaps. For a plywood top, drill and screw it securely.

4. Add Clamping Features If you’re incorporating T-slots or any clamping fixtures, now is the time to install them. Ensure they are evenly spaced and easy to access.

5. Finish If desired, paint or add a protective coating to prevent rust and wear on your welding table. Let it dry thoroughly before use.

6. Test for Stability After assembly, test the table under load to ensure it can withstand the weight and heat generated during welding.

Creating your own welding table can be a rewarding project that significantly enhances your metalworking capabilities. With careful planning and execution, you can build a custom table that meets your specific needs, resulting in improved safety, efficiency, and quality in your welding projects. Happy welding!

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS