Aug . 21, 2024 21:47 Back to list

Durable Cast Iron Floor Plates for Industrial and Commercial Applications

The Significance of Cast Iron Floor Plates in Industrial Applications

Cast iron floor plates are integral components in various industrial settings, renowned for their durability and precision. These heavy-duty fixtures are used primarily in machine shops, factories, and laboratories for supporting heavy machinery, measuring instruments, and tools. The importance of cast iron floor plates cannot be overstated, as they provide a stable and reliable foundation for a variety of applications ranging from manufacturing to assembly processes.

Composition and Properties

Cast iron is a group of iron-carbon alloys with a carbon content greater than 2%. Its high carbon content lends itself to a range of advantageous properties, which make it an ideal material for floor plates. One of the most significant characteristics of cast iron is its excellent compressive strength, making it capable of supporting heavy loads without deformation. Additionally, cast iron exhibits remarkable wear resistance, which is crucial in environments where there is constant friction or movement.

The material's ability to absorb vibrations is another key benefit, which helps in maintaining the precision of tools and machines placed on the plates. This quality is essential for machining processes where even the slightest movement can lead to inaccuracies and defects in the final product. Furthermore, cast iron's inherent stability and resistance to thermal expansion enable it to maintain its shape over time, even when subjected to temperature fluctuations.

Applications of Cast Iron Floor Plates

In industrial settings, cast iron floor plates are commonly used as a base for precision machining operations. They provide a flat, stable surface that allows for accurate measurements and operations. Engineers and machinists rely on these plates when performing tasks that require high precision, such as grinding, drilling, or milling.

cast iron floor plate

In addition to their use in machining, cast iron floor plates serve as bases for inspection and testing. Quality control processes depend on stable, level surfaces to ensure that measurements are accurate and comply with industry standards. By placing measuring instruments and gauges on cast iron floor plates, technicians can be confident that their readings are reliable.

Moreover, these floor plates have applications in educational institutions and research laboratories. They are commonly used for experiments that require precise measurements and controlled environments. The rigidity and stability of cast iron floor plates help foster an ideal setting for a variety of scientific inquiries.

Advantages and Considerations

While the advantages of cast iron floor plates are numerous, there are also considerations to keep in mind. The weight of these plates means that they require careful handling during installation. Additionally, they can be prone to rusting if not properly maintained, emphasizing the importance of regular cleaning and protective coatings.

Another consideration is the cost. While cast iron floor plates are more expensive than those made from lighter materials, their long-term durability and performance often justify the initial investment. In many cases, the reliability and precision provided by cast iron far outweigh the upfront costs, making them a wise choice for industries where quality and accuracy are paramount.

Conclusion

In summary, cast iron floor plates are essential components in various industrial applications, offering a combination of strength, stability, and precision. Their unique properties make them suitable for heavy-duty tasks, while their durability ensures that they can withstand the demands of daily use. As industries continue to evolve, the role of cast iron floor plates remains critical in facilitating accurate measurements and maintaining high standards of quality in manufacturing and testing environments. Investing in high-quality cast iron floor plates can invariably lead to improved operational efficiency and superior product outcomes.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

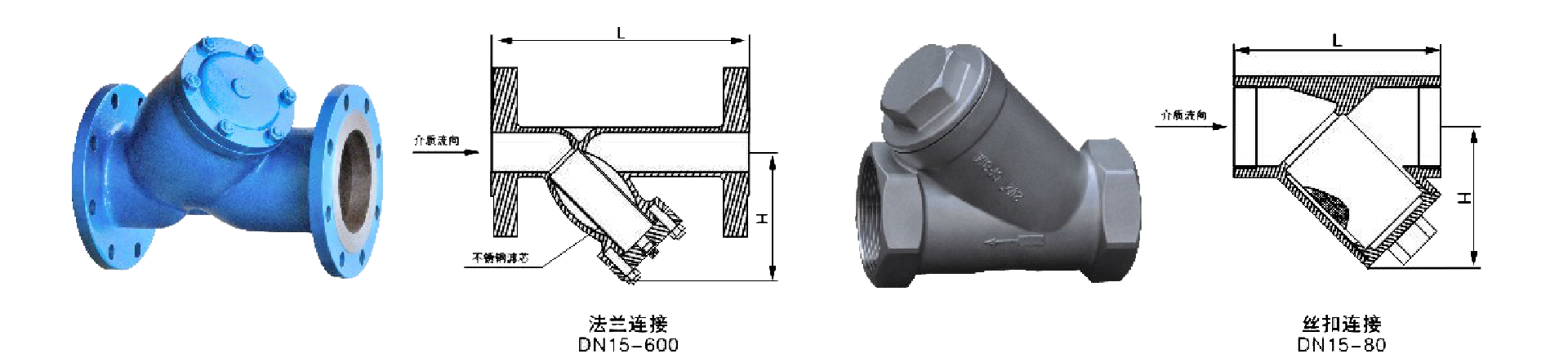

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS