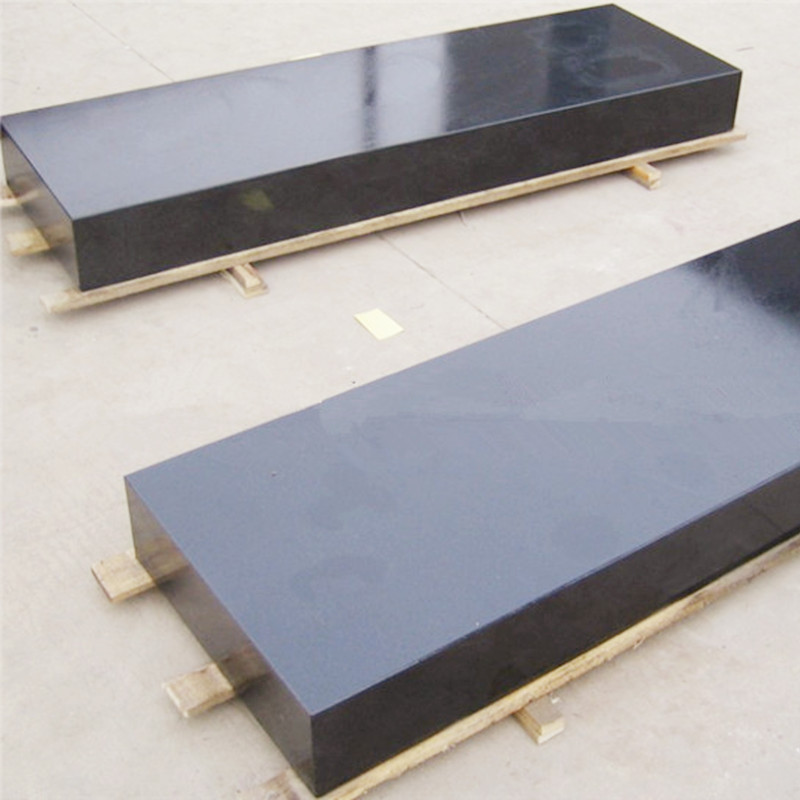

Granite Inspection Surface Plate

Product Description

A Granite platform is a platform product made of granite processed by machine tools and manually ground in a constant temperature chamber, with high flatness accuracy.

Physical parameters of granite platform:

Specific gravity: 2970-3070kg/m3;

Compressive strength: 245-254kg/m

m2;

Elastic wear: 1.27-1.47N/mm2;

Linear expansion coefficient: 4.6 × 10-6/℃;

Water absorption rate of 0.13;

Shore hardness of HS70 or above.

The accuracy of granite platforms is much higher than that of cast iron platforms. This is because granite has undergone long-term aging treatment and no longer has internal stress. The accuracy levels of 000, 00, 0, and 1 are ideal tools for marking and inspection in processing enterprises.

Place of Origin: Hebei, China

Warranty:1 year

Customized support: OEM, ODM, OBM

Brand Name: Storan

Model Number:1006

Material:Granite

Color: blank

Specification:200X200mm-3000X5000mm or customize

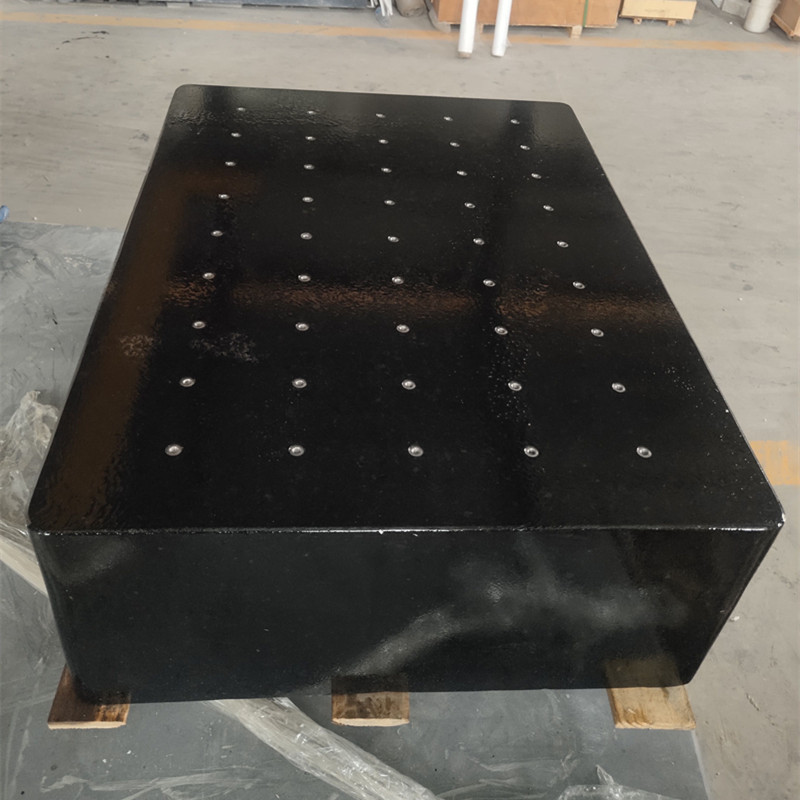

Surface: flat, tapped holes, T-slots, etc.

The hardness of the Working Surface: HS70

Surface Treatment: ground finish

Precision Grade:0-2

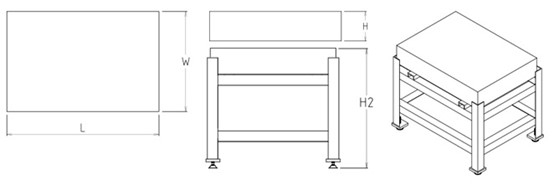

Stand: available

Packaging:p lywood box

Usage :precision gauging, inspection, layout,t and marking purposes

Packaging Details: Plywood box

Supply Ability:20000 Pieces/Pieces per Year

Lead time:

|

Quantity (pieces) |

1 - 1 |

> 1 |

|

Lead time (days) |

30 |

To be negotiated |

Product Description

Granite Surface Plate:

Granite Surface Plates are best known due to their rust-less properties. The hardness of the granite surface plates is also more

than the Cast Iron Surface Plates. They are wildly used for precision gauging, inspection, layout and marking purposes and

preferred by Laboratories, Engineering Industries and Workshops.

Material: Granite

Specification: 1000X750mm-3000X4000mm or customize

Surface: flat, tapped holes, T-slots, etc.

Hardness of the working surface: HS70

Surface treatment: ground finish

Precision grade: 0-2

Packaging: plywood box

Product Detail Drawing

Customized Common Parameters

|

No. |

Width X Length(mm) |

Precision Grade |

|

|

0 |

1 |

||

|

Flatness (μm) |

|||

|

1 |

200X200 |

3.5 |

|

|

2 |

300X200 |

4 |

|

|

3 |

300X300 |

4 |

|

|

4 |

300X400 |

4 |

|

|

5 |

400X400 |

4.5 |

|

|

6 |

400X500 |

4.5 |

|

|

7 |

400X600 |

5 |

|

|

8 |

500X500 |

5 |

|

|

9 |

500X600 |

5 |

|

|

10 |

500X800 |

5.5 |

|

|

11 |

600X800 |

5.5 |

|

|

12 |

600X900 |

6 |

|

|

13 |

1000X750 |

6 |

|

|

14 |

1000X1000 |

7 |

|

|

15 |

1000X1200 |

7 |

|

|

16 |

1000X1500 |

8 |

|

|

17 |

1000X2000 |

9 |

|

|

18 |

1500X2000 |

10 |

|

|

19 |

1500X2500 |

11 |

|

|

20 |

1500X3000 |

13 |

|

|

21 |

2000X2000 |

11 |

|

|

22 |

2000X3000 |

13 |

27 |

|

23 |

2000X4000 |

16 |

32 |

|

24 |

2000X5000 |

19 |

37 |

|

25 |

2000X6000 |

22 |

43 |

|

26 |

2000X7000 |

25 |

49 |

|

27 |

2000X8000 |

27.5 |

54.5 |

|

28 |

2500X3000 |

14.5 |

28.5 |

|

29 |

2500X4000 |

16.5 |

33 |

|

30 |

2500X5000 |

19.5 |

39 |

|

31 |

2500X6000 |

22 |

44 |

|

32 |

3000X3000 |

15.5 |

30.5 |

|

33 |

3000X4000 |

17.5 |

35 |

|

34 |

3000X5000 |

20 |

40 |

Why Granite Surface Plates are Essential for Precision Measurement

In the realm of precision measurement, granite surface plates stand as an indispensable tool for quality control and engineering applications. Their unique properties make them the preferred choice among precision engineers, machinists, and quality assurance professionals.

Granite surface plates are crafted from natural granite, known for their exceptional hardness, stability, and resistance to deformation. This solid foundation allows for accurate measurements, as it provides a flat, stable reference surface. Unlike other materials, granite does not warp or change shape over time, ensuring that measurements remain consistent and reliable.

One of the critical advantages of granite surface plates is their ability to withstand wear and tear from repeated use. This durability is vital in industrial settings where precision is paramount. Furthermore, granite is chemically resistant, allowing it to withstand exposure to oils, solvents, and other contaminants without losing its integrity. This characteristic is crucial in maintaining a clean workspace and ensuring that measurement equipment remains untainted.

Moreover, granite surface plates come in various sizes and configurations, catering to different applications. Whether utilized for inspecting machined parts, aligning equipment, or conducting intricate assembly tasks, these plates provide a versatile solution for various precision measurement needs. Their smooth surface can be easily cleaned and maintained, contributing to their long-term usability and accuracy.

In conclusion, granite surface plates are essential for any operation requiring high-precision measurements. Their durability, stability, and resistance to environmental factors make them the ideal choice for professionals in diverse fields. Investing in a granite surface plate not only enhances measurement accuracy but also ensures the longevity of your tools and equipment, making it a wise choice for any quality-focused organization.

The Role of Granite Surface Plates in Modern CNC Machining

In the realm of modern CNC (Computer Numerical Control) machining, precision is paramount. Among the various tools that facilitate this accuracy, granite surface plates stand out as a cornerstone of the machining process. Their role in CNC machining is both vital and multifaceted, providing a stable foundation that ensures optimal performance.

Granite surface plates are prized for their exceptional rigidity and stability. Made from natural granite, these plates offer a flat and hard surface that is essential for measuring and inspecting machined parts. The inert properties of granite also minimize the effects of temperature fluctuations, ensuring that precision measurements remain consistent over time. This stability is critical in CNC machining environments, where even the slightest deviation can lead to significant errors in the final product.

Moreover, granite surface plates come equipped with high wear resistance, enabling them to withstand the rigors of daily use in manufacturing settings. Unlike other materials, granite does not deform under pressure, preserving its flatness and accuracy even under heavy loads. Additionally, their non-porous nature aids in easy cleaning and maintenance, further contributing to their longevity.

In CNC machining, granite surface plates serve as essential tools not only for aligning and supporting workpieces during machining but also for precision measurement. These plates are crucial when calibrating CNC machines, as they provide reliable reference points to ensure that each component is processed correctly.

In conclusion, the role of granite surface plates in modern CNC machining cannot be overstated. They provide the necessary stability, durability, and accuracy that are critical for high-quality machining processes. As the industry continues to evolve, the reliance on granite surface plates will remain a key component in achieving manufacturing excellence.

Material Properties and Physical Advantages of Granite Inspection Surface Plates

STORAEN’s granite surface plates are engineered to deliver unmatched stability and precision as the foundation for industrial measurement, leveraging the unique material properties of natural granite to set the benchmark in metrology. As a trusted provider of precision granite surface plates and granite inspection tables, we offer solutions that excel in demanding environments, from CNC machining workshops to aerospace calibration labs.

Geological Foundation for Unmatched Stability

Formed over billions of years from igneous rock composed primarily of pyroxene and plagioclase, our granite surface plates feature a dense, uniform crystalline structure (grain size ≤0.5mm) that eliminates internal stresses—a critical advantage over metallic alternatives prone to warping or corrosion. This natural composition results in a strikingly consistent black surface with minimal porosity, providing an ideal flat reference for surface plate calibration and dimensional inspections where micron-level accuracy is non-negotiable.

Mechanical Properties Built for Heavy-Duty Use

The physical attributes of our granite inspection tables are optimized for industrial rigor:

High Load-Bearing Capacity: With a density of 2970 kg/m³ and compressive strength of 245 MPa, these plates withstand static loads up to 5000 kg/m² without deformation—perfect for supporting heavy components during modular welding table setups or CNC machine calibration.

Exceptional Hardness: A Shore D hardness of 70+ resists scratches and indentations from frequent gauge or fixture contact, ensuring the surface remains free of defects that could compromise measurement integrity over decades of use.

Vibration Damping: The granular microstructure absorbs 80% more vibration than cast iron, minimizing interference from adjacent machinery—an essential feature for precision tasks like coordinate measuring machine (CMM) alignment.

Environmental Resilience for Consistent Accuracy

STORAEN’s granite surface plates for sale thrive in challenging conditions thanks to:

Thermal Stability: A low coefficient of linear expansion (4.6×10⁻⁶/°C) ensures minimal dimensional change across temperature ranges (10–30°C), reducing errors caused by thermal fluctuations in unconditioned workshops.

Corrosion Resistance: With a water absorption rate of just 0.13%, the non-porous surface repels oils, coolants, and moisture—eliminating rust or chemical degradation common in steel plates.

Zero Magnetic Permeability: Non-magnetic properties make these plates ideal for industries where electromagnetic interference could skew sensor-based measurements, such as semiconductor manufacturing or medical device testing.

Design Excellence for Practical Use

Beyond natural material advantages, our plates feature precision-machined details:

Surface Finish: A ground finish of Ra ≤0.8μm provides optimal contact for dial indicators, height gauges, and other metrology tools, ensuring repeatable results within ±2μm for 000-grade plates.

Modular Compatibility: Standard sizes (200×200mm to 3000×5000mm) and optional T-slots or mounting holes enable seamless integration with modular welding tables or custom fixtures, enhancing versatility in production and inspection workflows.

Trust STORAEN for Material-Driven Precision

When accuracy and longevity are non-negotiable, STORAEN’s granite surface plates deliver the natural and engineered advantages required to elevate your metrology processes. Whether used as a standard for surface plate calibration, a stable platform for aerospace component inspection, or a durable base for heavy-duty welding setups, our solutions combine geological perfection with industrial-grade design.

Customization Services and Quality Assurance for STORAEN Granite Inspection Surface Plates

STORAEN takes pride in delivering granite surface plates that meet the unique demands of your precision measurement and industrial applications. Beyond standard offerings, our customization services and rigorous quality assurance ensure every precision granite surface plate and granite inspection table is tailored to your specifications—backed by certifications and guarantees that inspire confidence in every measurement.

Tailored Solutions for Every Requirement

Custom Sizing & Geometry

Whether you need a compact granite inspection table for lab use (200×200mm) or an oversized platform for heavy machinery (up to 5000×8000mm), our engineers work with you to define dimensions, thickness, and shape—including circular, rectangular, or non-standard designs. Custom edge profiles (chamfered, beveled) and recessed bases enhance stability when integrating with modular welding tables or automated fixtures.

Surface Features for Functional Excellence

T-Slots & Mounting Holes: Precision-machined T-slots (ISO 2571 standard) or threaded holes (M6–M24) enable secure clamping of gauges, fixtures, or robotic arms, ideal for dynamic inspection setups or modular welding table configurations.

Specialized Coatings: Optional anti-static or anti-slip coatings protect against dust accumulation or component slippage in semiconductor or medical device manufacturing environments.

Multi-Platform Compatibility

Our granite surface plates are designed to integrate seamlessly with coordinate measuring machines (CMMs), height gauges, and surface plate calibration systems, with pre-machined reference points for traceable measurements across global standards (ISO 8512, ASME B89.1.3).

Uncompromising Quality Assurance Process

Material Selection & Inspection

Every slab starts with premium-grade granite (grain size ≤0.5mm, water absorption ≤0.13%), visually and ultrasonically tested to eliminate internal flaws. Only rock with uniform density (2970 kg/m³+) and Shore D hardness ≥70 proceeds to machining.

Precision Manufacturing

Grinding & Polishing: State-of-the-art CNC grinders achieve surface finishes as fine as Ra 0.8μm, with planar flatness controlled to ±2μm for 000-grade plates—verified using laser interferometers.

Thermal Stress Relief: Plates undergo 72-hour stabilization at 20±2°C to eliminate residual machining stresses, ensuring long-term dimensional stability in fluctuating workshop environments.

Warranty & After-Sales Support

Global Service Network: For granite surface plates for sale worldwide, our team provides installation guidance, periodic recalibration services, and rapid response to technical inquiries—ensuring your investment maintains peak performance for decades.

Choose STORAEN for Customized Precision

Whether you require a bespoke granite inspection table for aerospace component alignment, a heavy-duty granite surface plate for industrial welding fixtures, or a calibrated platform for lab-grade metrology, STORAEN’s customization and quality assurance set the standard. Our commitment to matching your exact needs with geological durability and engineering precision makes us the partner of choice for manufacturers who refuse to compromise on measurement integrity. Explore our granite surface plates for sale today and experience the power of a solution built exclusively for you.

Related PRODUCTS

RELATED NEWS

Thread Plug Gauge Our Promise of Measurement Excellence

At Storaen (Cangzhou) International Trading Co., we manufacture precision thread plug gaug

Gauge Pin Class Reflecting Quality Legacy

At Storaen (Cangzhou) International Trading Co., we manufacture precision pin gauge i

Check Valve Types for High Rise Buildings

At Storaen (Cangzhou) International Trading Co., we specialize in engineering premium chec