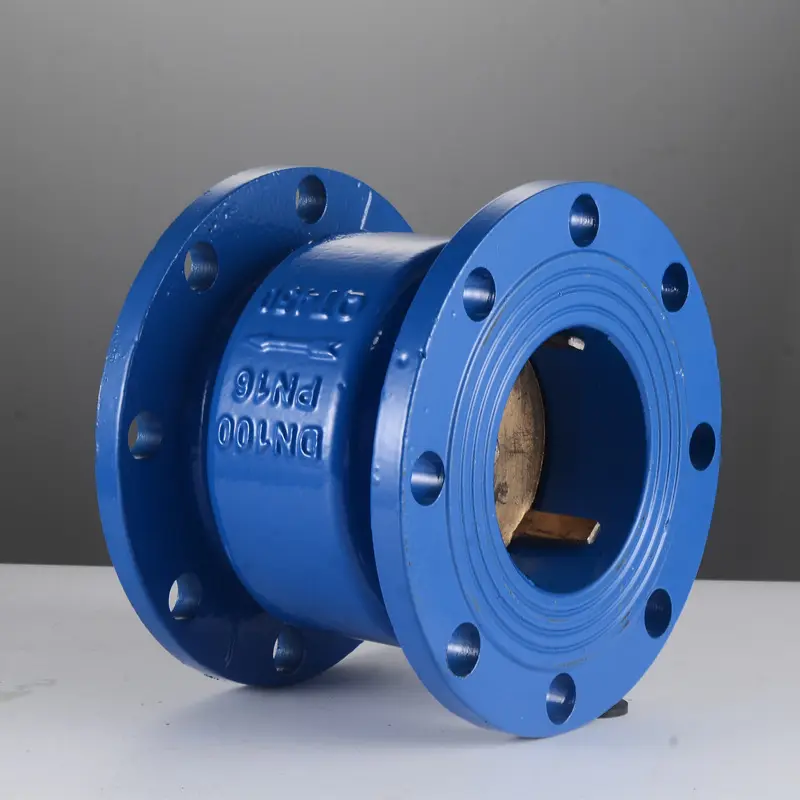

Silencing Check Valve

Product Description

The role of the muffler check valve is to prevent the flow in the opposite direction, only allowing the medium to flow in one direction. Usually, this valve is automatic, in a direction of flow of fluid pressure, valve open; fluid flow in the opposite direction, by the fluid pressure and the valve flap of the self-gravity of the valve flap on the valve seat, thus cutting off the flow. Not suitable for use in media containing solid particles and viscosity.

What is a Silent Check Valve?

A silent check valve, an essential component in various piping systems, is designed to prevent backflow while minimizing hydraulic shock. Unlike traditional check valves that rely on a weighted disc or ball, silent check valves use a unique mechanism that significantly reduces noise during operation. This feature makes them particularly advantageous in applications where noise levels need to be kept to a minimum, such as in residential and commercial plumbing, HVAC systems, and fire protection systems.

The primary function of a silent check valve is to allow fluid to flow in one direction while automatically closing to prevent reverse flow. This is achieved through a spring-loaded mechanism that responds quickly to changes in fluid pressure. When the flow stops or begins to reverse, the valve’s disc closes tightly to prevent any backflow, effectively safeguarding the integrity of the system and protecting equipment from potential damage.

One of the key benefits of silent check valves is their ability to reduce water hammer, a phenomenon that occurs when fluid in motion is forced to stop suddenly, creating pressure surges that can lead to pipe damage and noise. The design of silent check valves mitigates these occurrences by providing a smoother transition for the flow of fluids, thus enhancing the overall longevity and performance of piping systems.

In commercial and industrial applications, the installation of silent check valves can lead to significant savings in maintenance costs and repairs caused by leaks or equipment failure. Their reliable function in ensuring unidirectional flow, along with the added advantage of noiseless operation, makes silent check valves a preferred choice for engineers and system designers.

In summary, a silent check valve is a crucial device for maintaining effective flow control and preventing backflow, with noise reduction properties that set it apart from traditional alternatives.

Dual Defense: Noise Cancellation & Water Hammer Protection – How Silencing Check Valves Quiet Pump Rooms

STORAEN’s silencing check valve revolutionizes pump system safety and comfort by integrating two critical functions—water hammer prevention and noise reduction—into a single, engineered solution. Unlike traditional check valves that cause disruptive “hammering” noises and destructive pressure surges, our design combines a spring-loaded slow-closing mechanism with noise-dampening materials, making it ideal for commercial buildings, industrial plants, and residential complexes where quiet operation and pipeline protection are non-negotiable.

1. Water Hammer Protection: The Science of Controlled Closure

At the core of our silence check valve is a precision spring-loaded disc that ensures gradual closure, which suppresses water hammer:

Dual-Stage Shutoff: When pump flow stops, the disc closes 80% rapidly (within 0.5 seconds) to arrest backflow, then the final 20% closes slowly over 3–15 seconds (adjustable via a needle valve), reducing pressure surges to ≤1.3x working pressure—40% more effective than standard check valves.

Rugged Construction: A ductile iron or 316L stainless steel body withstands pressures up to 2.5MPa and temperatures from -10°C to 80°C, while a stainless steel spring resists corrosion, ensuring 50,000+ cycle life in harsh environments.

2. Noise Reduction: Engineered for Quiet Operation

Three design features work together to eliminate the harsh“slam” of traditional valves:

Rubber-Infused Sealing: An EPDM/NBR rubber-coated disc creates a soft, impact-absorbing seal, reducing closure noise by 40% compared to metal-to-metal contacts.

Streamlined Flow Path: A waist-shaped valve body minimizes turbulence during forward flow, cutting hydraulic noise (≤70dB) in half, critical for pump rooms adjacent to offices or living spaces.

Non-Metallic Lubrication Sleeve: A PTFE-coated guide sleeve reduces friction between the disc and valve body, eliminating the high-pitched squeaks common in unlubricated valves.

3. Versatile Design for Diverse Applications

Available in sizes from DN40 to DN500 with flange connections (ASME B16.5/GB/T 17241.6), our silencing check valves adapt to various systems:

Commercial Buildings: Install at pump outlets in high-rise water supply systems to protect pipelines and maintain tenant comfort.

Industrial Plants: Handle dirty water or mild slurries with a debris-resistant disc design, preventing clogging while reducing noise in manufacturing facilities.

Residential Systems: Quiet enough for residential pump rooms, with lead-free brass options meeting FDA standards for potable water.

Upgrade to Quieter, Safer Fluid Control

Don’t let noise and water hammer compromise your system’s performance. STORAEN’s silencing check valves deliver the dual protection you need—quiet operation and robust backflow prevention—engineered to extend pump life, reduce maintenance, and create more comfortable environments.

Whether you’re upgrading a commercial pump room or designing a residential water system, our silence check valves provide the perfect balance of safety and serenity. Explore our range today and discover why industries trust STORAEN for noise-free, reliable fluid control.

Swing vs. Lift Type: In-Depth Noise Reduction Principles of Silencing Check Valves

Choosing between swing-type and lift-type silencing check valves depends on understanding their unique noise reduction mechanisms and operational strengths. STORAEN offers both designs, each optimized for specific fluid control needs—here’s how they work and where they excel in creating quieter, safer pipeline systems.

1. Swing-Type Silencing Check Valves: Low-Noise Flow with Angular Movement

Swing-type valves feature a disc hinged at the top, rotating to open/close around a horizontal axis:

Noise Reduction Mechanism:

A rubber-coated disc (EPDM/NBR) and soft-seat design absorb impact during closure, reducing the “slam” noise by 35% compared to metal-only valves.

A dampening spring slows the disc’s rotation, ensuring gradual sealing even in low-pressure systems (≥0.05MPa), minimizing water hammer-related vibrations (noise ≤75dB).

Best For:

Large-diameter pipelines (DN80–DN600) in industrial water systems or HVAC loops, where their full-bore design reduces pressure loss by 20% versus lift types.

Moderate-pressure applications (≤1.6MPa) with clean media, as the hinged design is less prone to debris blockage.

2. Lift-Type Silencing Check Valves: Precision Closure for High-Pressure Quietness

Lift-type valves use a vertically moving disc guided by a stem, offering tighter control in high-pressure scenarios:

Noise Reduction Mechanism:

A dual-guide rail system stabilizes the disc’s vertical motion, eliminating lateral wobble and the metallic screeching common in unguided designs.

A short-stroke design (25–50mm) combined with a heavy-duty spring ensures rapid yet controlled closure (0.3 seconds for DN50), reducing pressure surge noise by 40% in systems up to 2.5MPa.

Best For:

Small to medium diameters (DN15–DN200) in residential or commercial buildings, where space is limited and quiet operation is critical (noise ≤65dB in domestic water systems).

High-pressure applications like boiler feed lines, thanks to their ability to handle temperatures up to 150°C with stainless steel 316 components.

Key Design Differences for Noise Control

Sealing Surface: Swing types use wide, angled seats for gradual contact; lift types rely on narrow, flat seats for instantaneous yet cushioned closure.

Flow Turbulence: Swing valves’ streamlined path reduces turbulence in low-speed flows; lift valves’ vertical stem creates minor resistance but excel in high-velocity, noise-prone environments.

Maintenance Needs: Lift valves’ guided stems require periodic lubrication (PTFE-coated sleeves in STORAEN models reduce friction by 30%); swing valves’ hinged joints need debris-free media to avoid sticking.

STORAEN’s Engineered Solutions for Every Scenario

Swing-Type Advantages: Optional epoxy lining for corrosive media, ASME B16.5 flanges for global compatibility, and noise tests compliant with ISO 3744 (acoustic engineering standards).

Lift-Type Innovations: Patented spring preload adjustment (0–10N·m) to fine-tune closure speed, ideal for customizing noise levels in sensitive environments like hospitals or hotels.

Choose the Right Type for Your System

Prioritize space & low pressure: Go with swing-type silence check valves for large pipelines.

Need high pressure & precision: Opt for lift-type silencing check valves in compact, high-demand setups.

Both designs from STORAEN ensure reliable backflow prevention while addressing noise at its source—whether through gradual angular closure or controlled vertical motion. Explore our range today and discover how our engineering expertise can deliver the quiet, efficient fluid control your system deserves.

Product Classification

1, rotary check valve: valve flap was disc-shaped, rotating around the valve seat channel axis for rotary motion, because the valve channel into a streamlined, flow resistance than the rise of butterfly check valve is small, suitable for low flow rate and flow of infrequent changes in large caliber occasions, but should not be used for pulsating flow, and its sealing performance is not as good as the lifting type. Butterfly check valve is divided into single-valve type, double-valve type and multi-valve type three kinds, these three forms are mainly according to the valve caliber to sub-division, the purpose is to prevent the medium from stopping the flow or backflow, weaken the hydraulic shock.

2, lift check valve: valve sliding along the vertical center line of the valve body check valve, muffler check valve can only be installed in the horizontal pipeline, in the high-pressure small diameter check valve valve valve can be used ball. The shape of the valve body of the muffler check valve is the same as that of the globe valve (which can be generalized with the globe valve), so its fluid resistance coefficient is larger. Its structure is similar to the globe valve, the valve body and valve flap and the same as the globe valve.

The upper part of the valve flap and the lower part of the valve cover are processed with guiding sleeve, and the valve flap guide can be freely lifted and lowered in the valve guide, when the medium flows downstream, the valve flap opens by the medium thrust, and when the medium stops flowing, the valve flap lands on the seat by self-pendant, and stops the medium from flowing backward. Straight-through butterfly check valve media inlet and outlet channel direction and valve seat channel direction perpendicular; vertical lift check valve, the media inlet and outlet channel direction and valve seat channel direction is the same, the flow resistance is smaller than straight-through.

3, tilting disk check valve: valve flap rotates around the pin in the valve seat check valve. More simple than the disc check valve structure, can only be installed in the horizontal pipeline, better sealing.

4, muffled check valve: valve flap sliding along the center line of the valve body. Pipeline check valve is a newly emerged valve, its small size, light weight, good processing technology, is one of the development direction of the check valve. But the fluid resistance coefficient is slightly larger than the swing check valve.

5, compression check valve: this valve is made for boiler feed water and steam cut-off valve, it has a lift check valve and globe valve or angle valve integrated function. In addition, there are - some do not apply to the pump outlet installation of check valves, such as bottom valve, spring-loaded, Y-type check valve.

Structure diagram of energy-saving muffler check valve:

Product Parameter

|

DN(mm) |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

|

L |

90 |

100 |

110 |

130 |

145 |

165 |

180 |

|

DN(mm) |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

|

L |

200 |

220 |

240 |

260 |

280 |

300 |

320 |

Characteristic Uses

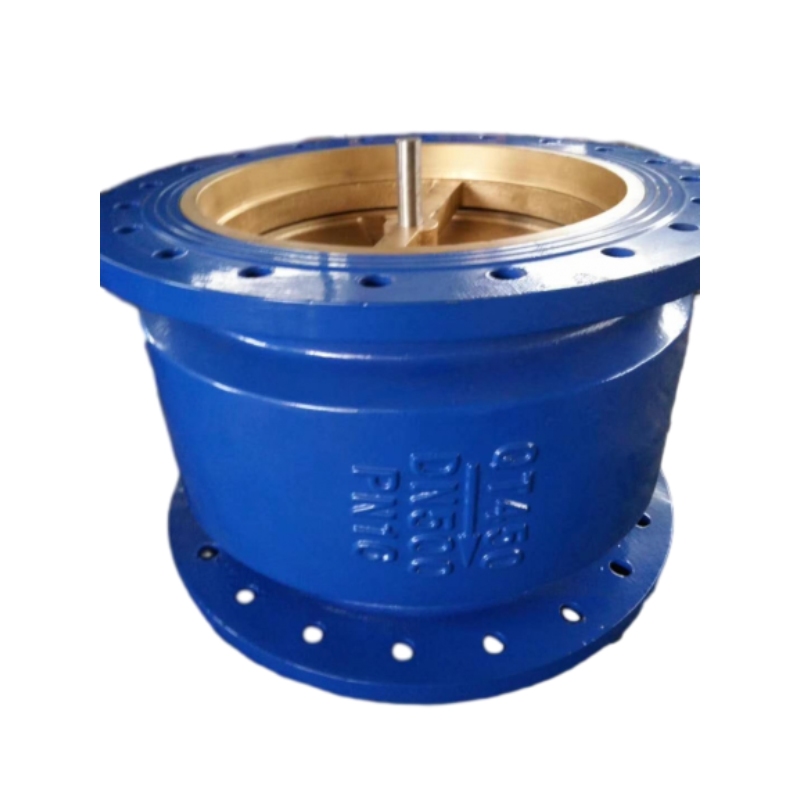

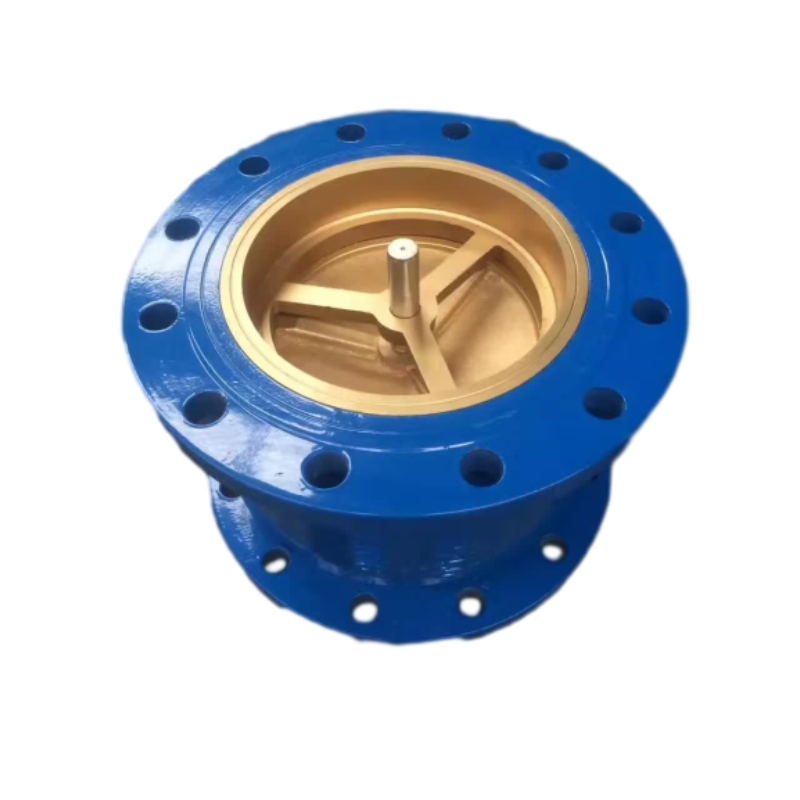

1、 The valve body adopts a "waist drum" shape design, improves the medium flow direction, reduce the flow resistance coefficient.

2, the valve adopts a short structure form, although the head loss is slightly larger than the lifting mute check valve, but the volume is small and cheap.

3、Compact structure, non-metallic lubrication sleeve is installed between guide shaft and guide frame, the valve flap is flexible, and will not produce holding phenomenon.

4, skeleton rubber seal ring set directly in the valve body, to avoid the medium for a long time on the direct scouring of the seal ring, the service life is significantly extended, sturdy and durable.

5、Short opening and closing strokes of the valve flap can effectively prevent water hammer.

6、Applicable to water supply and drainage systems, high-rise building network, can be installed at the outlet of the pump, the structure is slightly modified, can be used as a suction bottom valve, but not for sewage network.

Principle structure

1, the valve in use, the media flow in the direction of the arrow shown.

2, when the media flow in the specified direction, the valve flap by the role of media force, be opened; media countercurrent, due to the self-weight of the valve flap and the valve flap by the role of the media reverse force, so that the valve flap and the sealing surface of the valve seat closed to prevent the purpose of the media countercurrent.

3、The sealing surface of valve body and valve flap is welded with stainless steel.

4、Structure length conforms to GB/T12221-2005 standard, flange connection conforms to GB/T17241.6-2008 standard.

Installation and use

1, the valve access to both ends shall be blocked, and the existence of dry and ventilated indoors. If stored for a long time, it should be checked frequently to prevent rust and corrosion.

2、The valve shall be cleaned before installation and defects caused during transportation shall be eliminated.

3、Installation must be carefully checked on the valve signs and nameplates to ensure compliance with the use of requirements.

4、The valve is installed on the horizontal pipeline with the bonnet upward.

Silent Check Valve FAQs

What is a silent check valve, and how does it work?

A silent check valve is a mechanical device that allows fluid to flow in one direction while preventing backflow. It operates using a hinged disc or a spring mechanism that opens when the fluid pressure on the inlet side exceeds the pressure on the outlet side. As the flow decreases or reverses, the valve closes silently, minimizing water hammer and vibrations, making it an ideal choice for residential and industrial applications alike.

What materials are the silent check valves made from?

Our silent check valves are constructed from high-quality materials such as brass, stainless steel, or PVC, depending on the specific model. These materials are engineered for durability and resistance to corrosion, ensuring a long service life and reliable performance in various fluid transport systems.

Can I install the silent check valve in any orientation?

While silent check valves are designed to be versatile, it’s essential to install them according to the manufacturer's instructions. Typically, these valves should be installed in a horizontal position, with the flow direction indicated by an arrow on the valve body. This ensures optimal functionality and prevents issues related to backflow or premature wear.

How does the silent check valve minimize noise and water hammer?

The design of the silent check valve incorporates features that reduce noise and water hammer effects. The valves use a slow-closing mechanism that gently seats the disc back into the valve body instead of slamming shut. This gradual closure decreases the turbulent flow and minimizes hydraulic shock, ensuring quieter operation and extending the lifespan of your plumbing system.

What applications are suitable for using silent check valves?

Silent check valves are ideal for a wide range of applications, including plumbing systems, irrigation, wastewater management, and industrial fluid processes. They are particularly beneficial in systems where noise reduction is a priority or where backflow could cause operational disruptions. Whether for residential or commercial use, these valves ensure efficient and reliable fluid control.

How can I determine the right size of silent check valve for my system?

To determine the appropriate size of a silent check valve for your system, first assess the pipe size and the flow rate of the fluid you are working with. The valve size should match the nominal pipe size to ensure optimal flow and prevent restrictions. Additionally, consider the pressure rating and compatibility with the fluid type. If you require assistance, our experts are available to help guide you to the ideal choice for your specific needs.

Related PRODUCTS

RELATED NEWS

Why Metric Trapezoidal Thread is Ideal for Precision Motion Control

In precision motion control systems, the choice of thread design directly impacts performance, and metric trapezoidal thread has emerged as a superior solution for its unique combination of accuracy and durability.

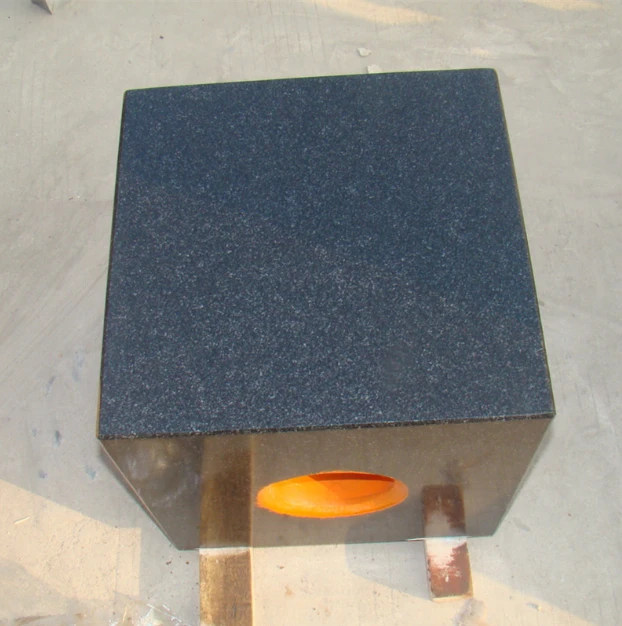

The Unique Properties of a Block of Granite for Industrial Use

In industrial manufacturing and precision measurement, the reliability of materials directly impacts operational accuracy, and a block of granite has emerged as an indispensable resource.

The Role of Flanged Y Strainers in Preventing Pipeline Clogs

In industrial pipeline systems, maintaining unobstructed flow is critical to operational efficiency, and flanged y strainer has emerged as a key component in achieving this goal.