Jan . 15, 2025 03:52 Back to list

y type strainer

Choosing the right filtration system for industrial processes is crucial. Among various options, the Y type strainer filter stands out due to its unique design and efficiency in handling a broad range of applications. Drawing from extensive experience and industry research, let's delve into the benefits and functionalities of this indispensable tool.

In terms of trustworthiness, the longevity and consistent performance of Y type strainers can be attributed to the high-quality materials used in their manufacture. Typically made from stainless steel or cast iron, these materials are selected for their ability to withstand high pressure and corrosive substances. Additionally, these strainers undergo rigorous quality control processes to ensure they meet industry standards, providing peace of mind to users about their operational safety and efficacy. The ease of maintenance further enhances the Y type strainer's appeal. Designed with a removable cover, these strainers allow for quick inspection and cleaning, reducing downtime during maintenance periods. This feature is particularly valuable in environments where continuous operation is critical, and frequent shutdowns can lead to significant productivity losses. In sum, the Y type strainer filter is much more than just a simple piece of equipment. It is a testament to engineering prowess, a protector of costly machinery, and a trusted ally in ensuring the integrity of industrial processes. Whether you're an engineer tasked with selecting the right filter for your system, or a procurement manager evaluating cost versus benefits, recognizing the advantages of a Y type strainer filter can make a significant difference in the efficiency and reliability of your operations. This filter is not just a component; it's an investment into a more seamless and efficient industrial future.

In terms of trustworthiness, the longevity and consistent performance of Y type strainers can be attributed to the high-quality materials used in their manufacture. Typically made from stainless steel or cast iron, these materials are selected for their ability to withstand high pressure and corrosive substances. Additionally, these strainers undergo rigorous quality control processes to ensure they meet industry standards, providing peace of mind to users about their operational safety and efficacy. The ease of maintenance further enhances the Y type strainer's appeal. Designed with a removable cover, these strainers allow for quick inspection and cleaning, reducing downtime during maintenance periods. This feature is particularly valuable in environments where continuous operation is critical, and frequent shutdowns can lead to significant productivity losses. In sum, the Y type strainer filter is much more than just a simple piece of equipment. It is a testament to engineering prowess, a protector of costly machinery, and a trusted ally in ensuring the integrity of industrial processes. Whether you're an engineer tasked with selecting the right filter for your system, or a procurement manager evaluating cost versus benefits, recognizing the advantages of a Y type strainer filter can make a significant difference in the efficiency and reliability of your operations. This filter is not just a component; it's an investment into a more seamless and efficient industrial future.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

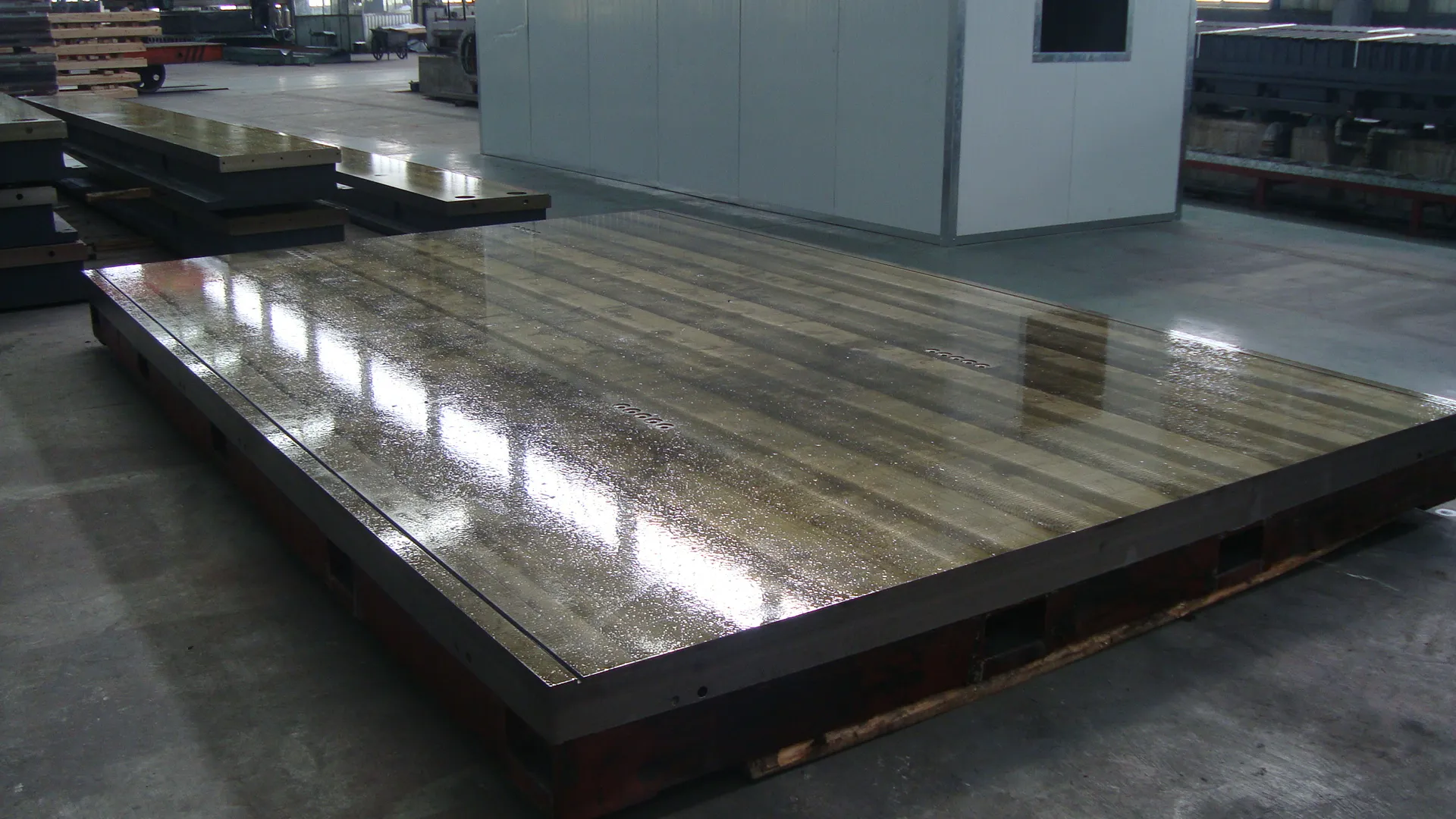

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS