Jul . 26, 2024 09:33 Back to list

Wood Connectors and Brackets for Building Strong and Durable Wooden Structures and Projects

Brackets for Connecting Wood An Essential Tool for Any Woodworking Project

When it comes to woodworking, using the right tools and techniques is critical to achieve both strength and aesthetics in your projects. Among the essential tools in a woodworker’s arsenal are brackets, especially designed for connecting wood elements securely. Brackets not only provide structural support but also allow for a variety of designs, making them invaluable in various woodworking applications.

Brackets are typically made from metal, although they can also be found in plastic or wood materials. The most common types of brackets used in woodworking include L-brackets, angle brackets, and flat brackets. Each type serves a specific purpose but all share a common goal to strengthen connections between wood pieces.

L-Brackets are perhaps the most recognizable and widely used type of bracket. Shaped like an “L,” these brackets are commonly employed to reinforce corner joints where two pieces of wood meet at a right angle. They create a strong bond that can resist both vertical and horizontal forces, making them ideal for furniture construction, shelving, and cabinetry. L-brackets are often used in the assembly of bookcases, tables, and other furniture items where stability is crucial.

Angle Brackets, similar to L-brackets but often with slightly different dimensions, are used in situations where both strength and stability are necessary. They are particularly useful in constructing frames or support structures where diagonal bracing is required. For example, when building outdoor furniture or garden structures, angle brackets can effectively handle weather-induced stress, ensuring that the construction remains intact.

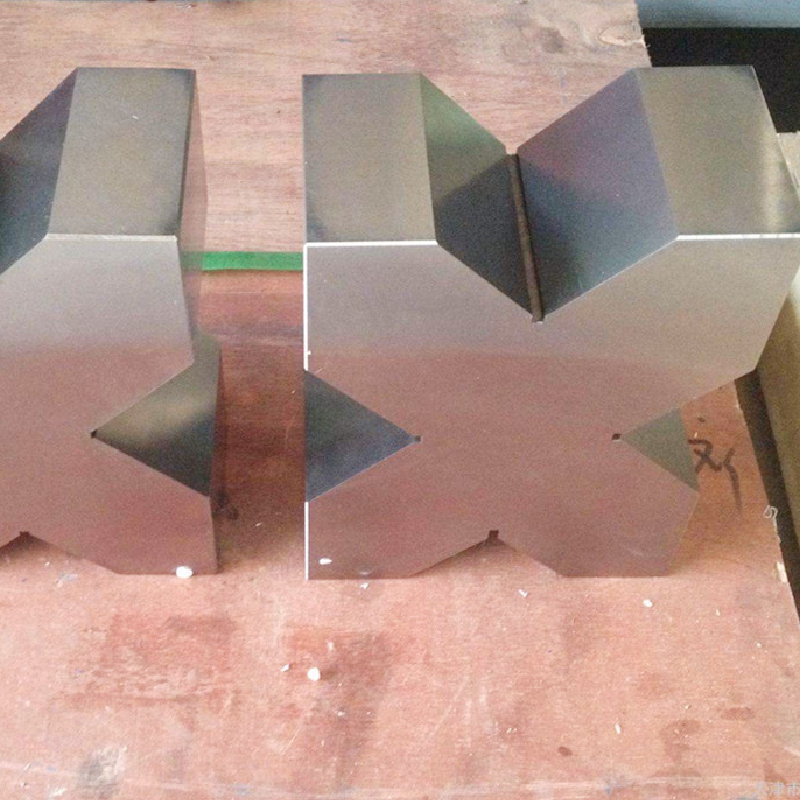

brackets for connecting wood

Flat Brackets serve a different purpose. They are mounted between two surfaces to create a stable connection that is less visually intrusive. This makes them popular for applications such as attaching legs to tabletops, where a clean finish is desired. Flat brackets can be very effective in reinforcing joints without compromising the design aesthetic.

One of the main advantages of using brackets in woodworking is the ease of installation. Most brackets come with pre-drilled holes, allowing woodworkers to quickly and securely fasten them using screws. This can significantly speed up the assembly process compared to traditional woodworking joints, which often require more time and skill to achieve the same level of strength.

Moreover, brackets offer versatility in woodworking projects. They can be painted or coated to match the wood, providing uniformity in appearance. Some woodworkers even choose to showcase the brackets as a design element, opting for decorative styles that enhance the overall look of their projects.

When incorporating brackets into your woodworking projects, it’s essential to choose the right size and type for your specific application. Factors such as weight loads, types of joints, and aesthetic considerations all play a role in this decision. Using inadequate brackets can lead to structural failure, while oversized brackets can detract from the beauty of your work.

In conclusion, brackets for connecting wood are vital tools that every woodworker should have. They enhance the strength and durability of projects, simplify the construction process, and can contribute to the visual appeal of a finished piece. Whether you are a hobbyist crafting a modest furniture item or a professional carpenter tackling intricate designs, understanding how to effectively use brackets will undoubtedly elevate the quality and longevity of your woodworking projects. Investing in the right brackets and learning how to incorporate them strategically can make all the difference in achieving successful and stunning woodworking outcomes.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS