Sep . 01, 2024 04:34 Back to list

Welding Fabrication Services | Precision Welding & Custom Fabrication

Understanding Welding and Fabrication A Comprehensive Overview

Welding and fabrication are critical processes in various industries, including construction, manufacturing, and automotive. These techniques involve joining materials, typically metals, to create structures or components. Understanding the fundamentals of welding and fabrication can help engineers, technicians, and designers choose the right methods and materials for their projects.

Understanding Welding and Fabrication A Comprehensive Overview

Fabrication, on the other hand, refers to the process of creating structures by cutting, bending, and assembling materials. This process usually involves several machining techniques, including laser cutting, plasma cutting, and CNC (Computer Numerical Control) machining. Fabricators must consider factors such as material properties, tolerances, and the intended use of the final product when selecting processes.

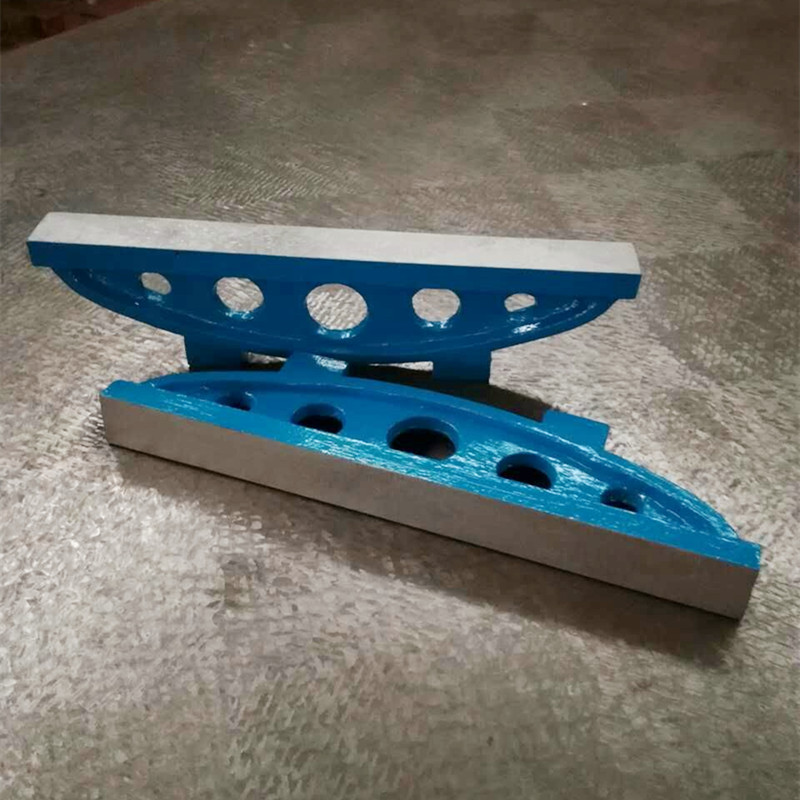

welding fabrication table

A key aspect of both welding and fabrication is the choice of materials. Common materials used in these processes include carbon steel, stainless steel, aluminum, and alloys. Each material has unique properties that influence the selection of welding techniques. For instance, stainless steel is often chosen for its corrosion resistance, while aluminum is favored for its lightweight characteristics.

Safety is paramount in welding and fabrication environments. Workers must be equipped with appropriate personal protective equipment (PPE) to prevent injuries from sparks, intense heat, and harmful fumes. Training programs focusing on safety protocols and equipment handling are essential to creating a safe working environment.

Quality control is another crucial element in welding and fabrication. Ensuring the integrity of welds and the overall structure is vital for the safety and performance of the final product. Various testing methods are employed to assess the quality of welds, including visual inspection, ultrasonic testing, and X-ray examination. Certification standards, such as those set by the American Welding Society (AWS), provide guidelines for ensuring high-quality workmanship.

In conclusion, welding and fabrication are integral to numerous industries, requiring a combination of technical skills, safety awareness, and a thorough understanding of materials and processes. As technology advances, the welding and fabrication industry continues to evolve, incorporating new techniques and equipment to improve efficiency and quality. For anyone involved in these fields, staying updated with the latest trends and best practices is essential for success and safety in their projects. Whether you are just starting or are a seasoned professional, understanding the welding and fabrication table of processes, materials, and safety measures will significantly enhance your work and ensure the longevity of the structures you build.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS