Dec . 15, 2024 08:07 Back to list

valve gate valve

Understanding Valve Gate Valves A Comprehensive Overview

Valve gate valves are essential components in various industrial processes, serving as critical control devices for fluid and gas management. Their unique design and functionality allow them to offer precise flow regulation, making them suitable for applications across different sectors, including oil and gas, chemical processing, water treatment, and power generation.

What is a Valve Gate Valve?

A valve gate valve, often referred to simply as a gate valve, is a type of valve that operates by lifting a rectangular or circular gate out of the path of the fluid. This lifting motion completely opens or closes the flow path, leading to an unobstructed flow when fully opened and a tight seal when closed. The primary purpose of a valve gate valve is to provide a straight-line flow with minimal pressure loss, an advantage particularly important in high-flow applications.

Design and Operation

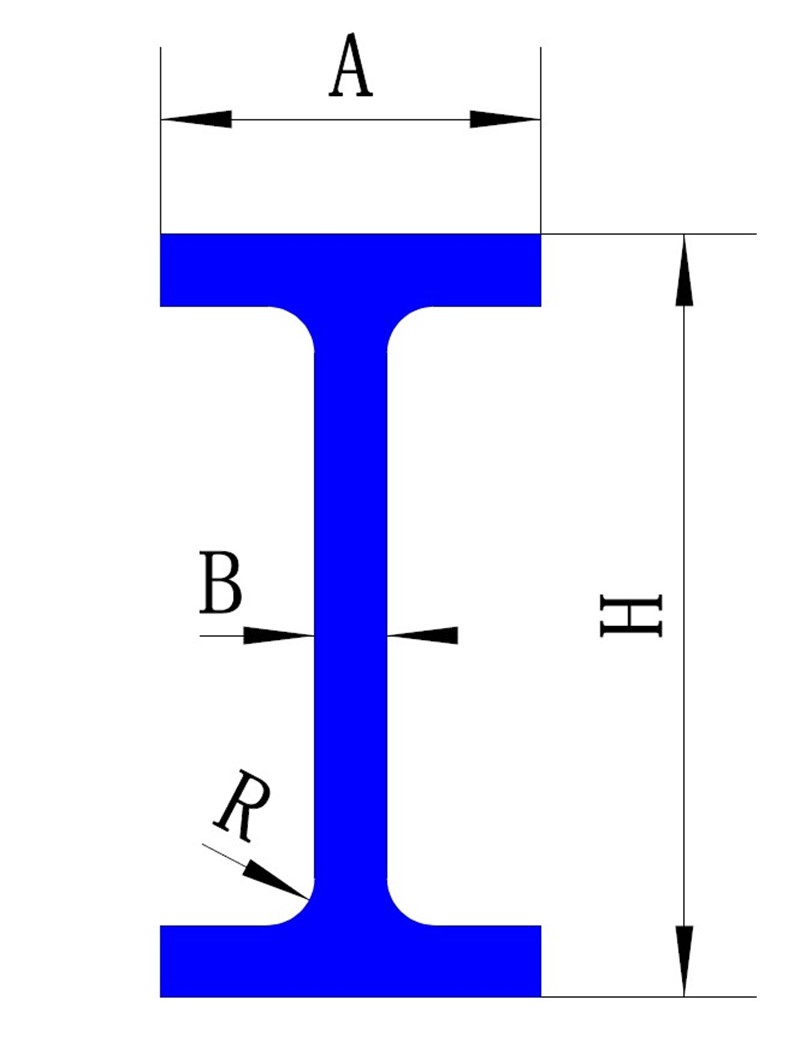

The design of a valve gate valve typically includes a body, a gate (or wedge), and a stem. The gate is positioned between two seats, and as the stem is turned, it lifts or lowers the gate to control the flow of the medium. One of the most notable features of gate valves is that they are either fully opened or fully closed, making them ideal for on/off applications but less suitable for throttling purposes. This on/off capability reduces the risk of wear and tear on the sealing surfaces, extending the lifespan of the valve in many cases.

Advantages of Valve Gate Valves

- Minimal Pressure Drop When fully open, valve gate valves offer a straight path for fluid flow, resulting in minimal resistance and pressure drop. This characteristic is particularly beneficial in applications where maintaining flow efficiency is crucial. - Durability Made from robust materials such as stainless steel, brass, and various alloys, valve gate valves are designed to withstand harsh environments and high pressures, making them reliable for long-term use.

valve gate valve

- Versatility Valve gate valves can handle various media types, including water, steam, oil, and gas, which makes them versatile choices for many industries.

- Ease of Modification These valves can be adapted to suit the specific needs of a system, including the addition of actuators for remote operation, which enhances automation capabilities in modern industrial applications.

Applications

Valve gate valves are employed in numerous applications. In the oil and gas industry, they are widely used to control flow in subsea pipelines and refineries. In chemical manufacturing, their ability to handle corrosive substances makes them invaluable for transporting and controlling various chemicals. Additionally, in water treatment facilities, gate valves regulate water flow in large pipelines, ensuring effective treatment processes.

Challenges and Considerations

Despite their advantages, valve gate valves also have some limitations. For instance, they are not ideal for applications that require frequent opening and closing, as this can lead to wear and eventual failure of the gate or its sealing surfaces. Moreover, they are less effective in throttling applications because the partially opened gate can cause turbulence in the flow.

Conclusion

Valve gate valves are a fundamental component in fluid control applications, offering advantages that include minimal pressure drop, durability, and versatility across various industries. Understanding the functionality and applications of gate valves can assist engineers and operators in optimizing their systems for better efficiency and reliability. As technology continues to advance, innovations in valve design and materials are likely to enhance the performance and longevity of these crucial devices, reaffirming their role in modern industrial processes.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS