Dec . 04, 2024 09:48 Back to list

using v blocks

Utilizing V Blocks A Comprehensive Guide

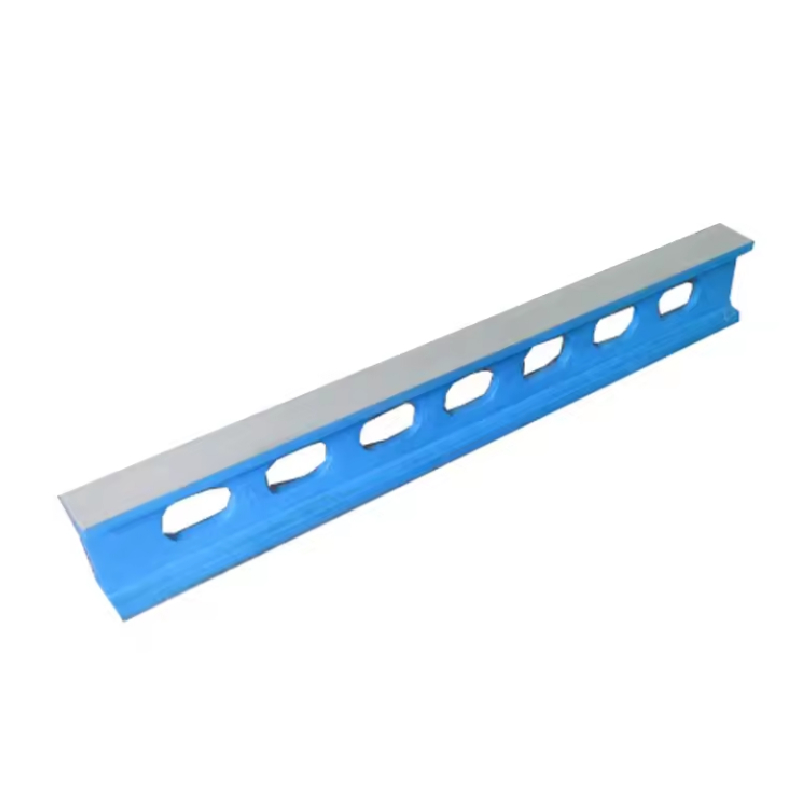

V blocks are essential fixtures in machining and manufacturing, renowned for their versatility and precision. These simple yet effective tools are designed to hold and support cylindrical or irregularly shaped workpieces during various machining operations. Understanding how to effectively use V blocks can significantly enhance productivity and accuracy in a workshop. In this article, we will explore the various applications, advantages, and best practices associated with V blocks.

What are V Blocks?

V blocks, also known as V blocks with clamps, are usually made from materials like steel, aluminum, or resin, depending on their intended application. The defining feature of V blocks is their V-shaped groove that holds round or tapered workpieces securely in place. This design allows for stable positioning during drilling, grinding, or other machining processes. V blocks are often used alongside other tools like surface plates and vises, forming a critical part of the setup for machining operations.

Applications of V Blocks

1. Precision Machining In precision machining tasks, V blocks provide a stable foundation for cylindrical parts. Used with a milling machine, they ensure that round pieces are positioned correctly for accurate cuts, holes, or other modifications.

2. Inspection and Measurement V blocks are commonly used for inspection and measurement purposes. Their ability to hold cylindrical objects securely allows operators to measure diameters, run-out, and other geometrical characteristics with precision.

3. Grinding Operations In grinding operations, particularly when using bench grinders or surface grinders, V blocks help maintain stability. By securing workpieces, operators can achieve better finishes and more accurate dimensions.

4. Welding and Fabrication In welding, V blocks assist in holding components securely in their desired positions. This stability is crucial for maintaining alignment during the welding process, ensuring that the final product meets specifications.

5. Assembly Tasks V blocks play a vital role in assembly tasks where alignment of parts is crucial. They help hold components in place, allowing for easier assembly and reducing the risk of misalignment.

Advantages of Using V Blocks

- Enhanced Stability The V-shaped groove provides an excellent grip on cylindrical workpieces, preventing them from rolling or shifting during machining operations.

using v blocks

- Versatility V blocks can accommodate a wide range of shapes and sizes, making them useful for various applications across different industries.

- Easy Setup Their simple design allows for quick and easy setup, enabling operators to spend more time on actual machining rather than adjusting fixtures.

- Cost-Effective Compared to specialized fixtures, V blocks are relatively inexpensive, offering a cost-effective solution for securing workpieces.

Best Practices for Using V Blocks

1. Proper Setup Ensure that the V block is securely mounted on the machine bed or surface plate. Any movement during operation can lead to inaccuracies.

2. Choose the Right Size Use V blocks that are appropriately sized for the workpiece. A block that is too small may not provide sufficient support, while one that is too large may hinder precision.

3. Use Clamps Wisely When using clamps with V blocks, position them correctly to avoid damaging the workpiece. Ensure that they do not obstruct machining areas or measurement points.

4. Regular Maintenance Keep V blocks clean and free of debris to maintain their effectiveness. Regularly inspect them for wear or damage, as any imperfections can impact their performance.

5. Combine with Other Tools For enhanced stability, consider using V blocks in combination with other tools such as angle plates or vises. This combination can provide even greater precision and support, particularly for complex or multi-faceted workpieces.

Conclusion

Utilizing V blocks effectively can greatly enhance the efficiency and accuracy of machining operations. Their simple yet functional design makes them indispensable in various applications, from precision machining to welding. By following best practices and understanding the advantages they offer, operators can ensure that their workpieces are secured properly, leading to improved outcomes in both productivity and product quality. Ultimately, V blocks are a worthwhile investment for any workshop focusing on precision and reliability.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS