Aug . 21, 2024 02:31 Back to list

Understanding Thread Gauges and Their Importance in Precision Measurement

Understanding Thread Gauges Essential Tools for Precision Engineering

Thread gauges are critical tools in the world of precision engineering, manufacturing, and quality control. These specialized devices are designed to measure and verify the dimensions of threaded fasteners, ensuring that they meet strict industry standards and specifications. In this article, we will explore the importance of thread gauges, their types, and their applications in various fields.

What is a Thread Gauge?

A thread gauge is a device used to check the sizes and forms of external and internal threads. It is primarily used to determine whether a threaded component, such as a bolt or nut, conforms to its designated standards. The proper functioning of machinery and equipment heavily depends on the accuracy of threaded connections, making thread gauges indispensable in various industries.

Types of Thread Gauges

1. Plug Gauges Plug gauges are used primarily to check the internal thread dimensions. They come in various sizes to fit different thread specifications, allowing operators to ensure that the internal threads of nuts or other components are adequately sized to accept the corresponding bolts.

2. Ring Gauges Similar to plug gauges but designed for external threads, ring gauges fit over the outside of a threaded component to assess its dimensions. This type of gauge is particularly useful in the automotive and aerospace industries, where external threads must maintain strict tolerances.

3. Thread Calipers These are versatile tools used by machinists to measure the pitch and diameter of threads. While thread calipers may require more skill to use accurately than plug or ring gauges, they provide a greater degree of flexibility in measuring different thread forms and sizes.

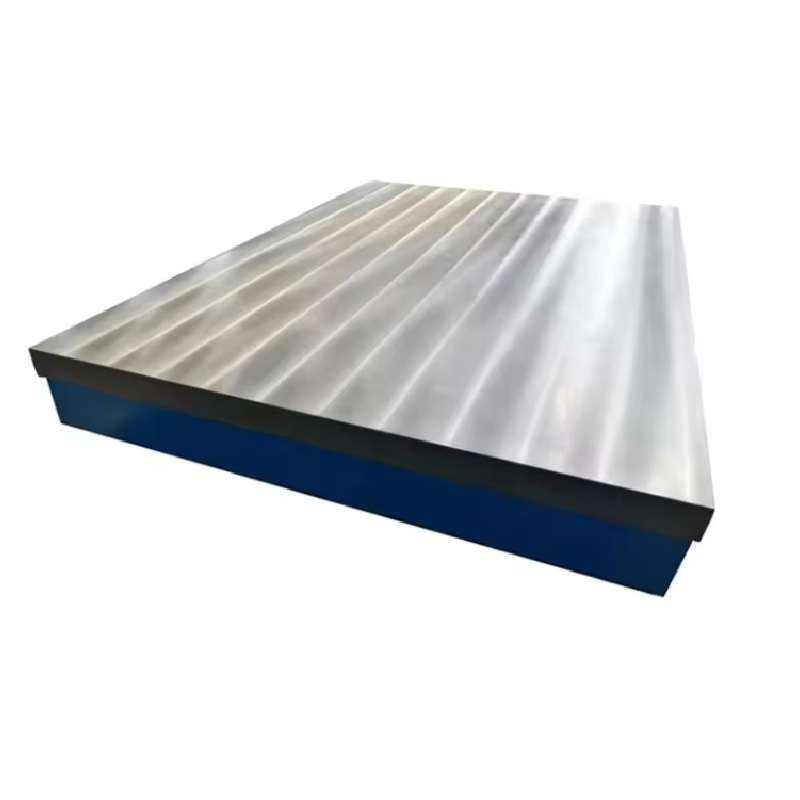

thread gauges

4. Go/No-Go Gauges This type of gauge determines whether the inspected thread meets the minimum or maximum size specifications. A Go gauge will indicate that a thread is acceptable, while a No-Go gauge will denote a thread that fails to meet standards. This binary assessment helps streamline quality control processes.

Applications of Thread Gauges

Thread gauges find extensive use across various sectors, including automotive, aerospace, construction, and manufacturing. In the automotive industry, for instance, ensuring the integrity of threaded fasteners is crucial for safety and performance. A failure in a bolt or nut can lead to catastrophic results, making thread gauges essential for parts inspection.

In the aerospace sector, where precision is paramount, thread gauges help maintain tight tolerances in components subjected to extreme conditions. Even a minor deviation in thread specifications can compromise the integrity of aircraft structures.

Furthermore, in construction and civil engineering, thread gauges are instrumental in verifying that components meet regulatory standards and specifications, thus ensuring the safety and reliability of buildings and infrastructure.

Conclusion

Thread gauges are vital tools that play an essential role in ensuring the reliability and safety of products across numerous industries. Their ability to measure and verify threaded dimensions allows manufacturers and engineers to produce components that adhere to precise specifications. Quality control processes benefit significantly from the use of thread gauges, which ultimately contribute to the overall integrity of mechanical assemblies. As industries continue to evolve and demand greater precision, the importance of thread gauges in maintaining quality will only increase, making them ever more crucial in the engineering landscape.

-

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal SystemsNewsAug.20,2025

-

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline ControlNewsAug.20,2025

-

Gate Valve Types: Understanding the Options for Your Pipeline SystemsNewsAug.20,2025

-

Y Type Strainer: Essential for Clean and Efficient Flow SystemsNewsAug.20,2025

-

Cast Iron Y Strainer: Durable Solutions for Demanding ApplicationsNewsAug.20,2025

-

Flanged Y Strainer: An Essential Component in Industrial Filtration SystemsNewsAug.20,2025

Related PRODUCTS