Aug . 19, 2024 18:58 Back to list

Understanding the Use of Ring and Plug Thread Gauges in Quality Control

Understanding Ring and Plug Thread Gages Essential Tools for Precision Measurement

In the world of manufacturing and engineering, precision is paramount. One of the essential components that contribute to ensuring the accuracy of threaded parts is the use of ring and plug thread gages. These specialized tools are critical for checking the pitch diameter, major diameter, and the form of threads, ensuring that components fit and function correctly in their designated applications.

What Are Ring and Plug Thread Gages?

Ring and plug thread gages are measuring instruments used to assess the quality of internal and external threads on various mechanical components. They help in measuring the dimensions of threaded parts to ensure they meet precise specifications defined by international standards. While both gages serve a similar purpose, they are designed for different types of threaded features.

Plug Gages Plug gages are primarily used for measuring internal threads, such as those found in nuts and tapped holes. They have a tapered or cylindrical shape that mimics the intended size and pitch of the threaded feature. The gage is inserted into the internal thread, and if it fits within a specific tolerance, the threads are considered acceptable. Plug gages come in various sizes to accommodate different thread dimensions.

Ring Gages On the other hand, ring gages are used for external threads, such as those on bolts and screws. These gages are shaped like rings and have a threaded inside diameter that matches the target thread. When an external threaded part is passed through the ring gage, it determines whether the external thread is within the required specification. Like plug gages, ring gages also have variations to cater to different sizes and pitches of external threads.

The Importance of Thread Gaging

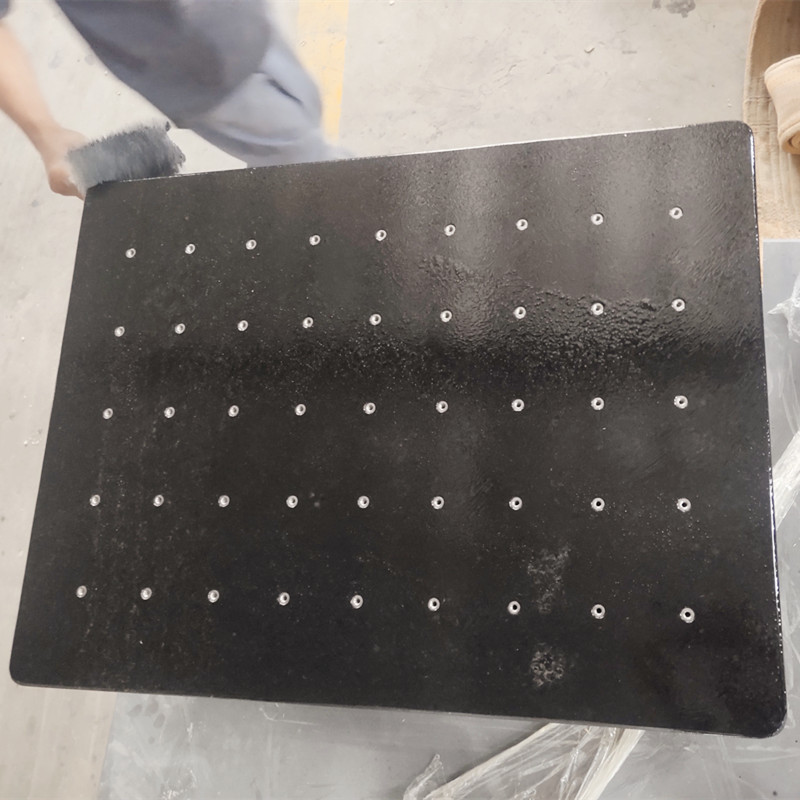

ring and plug thread gages

Thread gaging is crucial in industries such as aerospace, automotive, and manufacturing, where the reliability and safety of components are of utmost importance. Accurate measurement of threads ensures proper assembly, functionality, and performance of mechanical systems, thereby reducing the risk of failures caused by poorly fitting parts.

Using thread gages helps identify defects like misalignment, incorrect thread pitch, and profile deformation. These defects can lead to significant problems, including increased wear, operational inefficiencies, and, in worst-case scenarios, catastrophic failures. By incorporating a robust gaging process, manufacturers can enhance product quality, streamline production processes, and maintain compliance with industry standards.

Standards and Best Practices

When using ring and plug thread gages, it is essential to follow industry standards such as ASME B1.1 and ISO 965, which outline the specifications for unified threads, metric threads, and other thread forms. These standards provide guidelines for thread parameters, tolerances, and gaging techniques.

Regular calibration and maintenance of thread gages are vital for ensuring their accuracy and reliability. Periodic checks against master gages help confirm their measurement capabilities, and proper storage conditions protect them from damage and wear.

Conclusion

In summary, ring and plug thread gages are indispensable tools in ensuring the accuracy and reliability of threaded components in various applications. By providing precise measurements, these gages play a pivotal role in upholding quality standards in manufacturing and engineering. As technology continues to evolve, the importance of these tools will remain, serving as a foundation for high-quality production and safe, efficient mechanical systems. Investing in proper training and adherence to applicable standards will ensure that industry professionals are equipped to utilize these tools effectively, securing the integrity of their threaded components.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS