Aug . 13, 2024 01:46 Back to list

Understanding the Functionality and Applications of Hydraulic Check Valves in Fluid Systems

Understanding Hydraulic Check Valves Key Components in Fluid Control Systems

Hydraulic check valves are essential components in various fluid control systems, playing a crucial role in regulating the flow of liquids and gases. These devices are designed to allow fluid to flow in one direction while preventing backflow, thereby ensuring the efficient and safe operation of hydraulic systems. This article will explore the fundamental functions, types, applications, and benefits of hydraulic check valves.

Functionality of Hydraulic Check Valves

The primary function of a hydraulic check valve is to maintain the directional flow of fluid. When fluid flows in the intended direction, it opens the valve, allowing lubrication or hydraulic fluid to pass through. However, if there is a reversal in flow direction—for instance, due to a power failure or system malfunction—the check valve closes automatically to prevent backflow. This mechanism protects sensitive components within the system, such as pumps and actuators, from potential damage caused by reversed flow.

Hydraulic check valves operate based on a few fundamental principles. Most commonly, they utilize a poppet-type design where a movable element, often a ball or disk, seats against a valve seat, creating a seal. The force exerted by the moving fluid helps open the valve, while gravity or spring force assists in closing it when flow ceases or reverses.

Types of Hydraulic Check Valves

There are several types of hydraulic check valves, each designed for specific applications and environments

1. Swing Check Valve This type utilizes a swinging disc to allow flow in one direction and close against the valve seat when flow reverses. Swing check valves are commonly used in larger pipelines and can handle significant flow rates.

2. Ball Check Valve Featuring a ball that sits in a seat, this valve opens with forward flow and seals shut when backflow occurs. Ball check valves are known for their reliability and are often used in low to moderate pressure systems.

3. Spring Check Valve Incorporating a spring mechanism, this type allows flow in one direction and uses spring tension to close the valve. These are compact and effective for applications requiring quick response times.

4. Dual-Plate Check Valve This design incorporates two plates that pivot, allowing for lower flow resistance and minimizing pressure loss. It is best suited for high flow applications and is often used in water distribution systems.

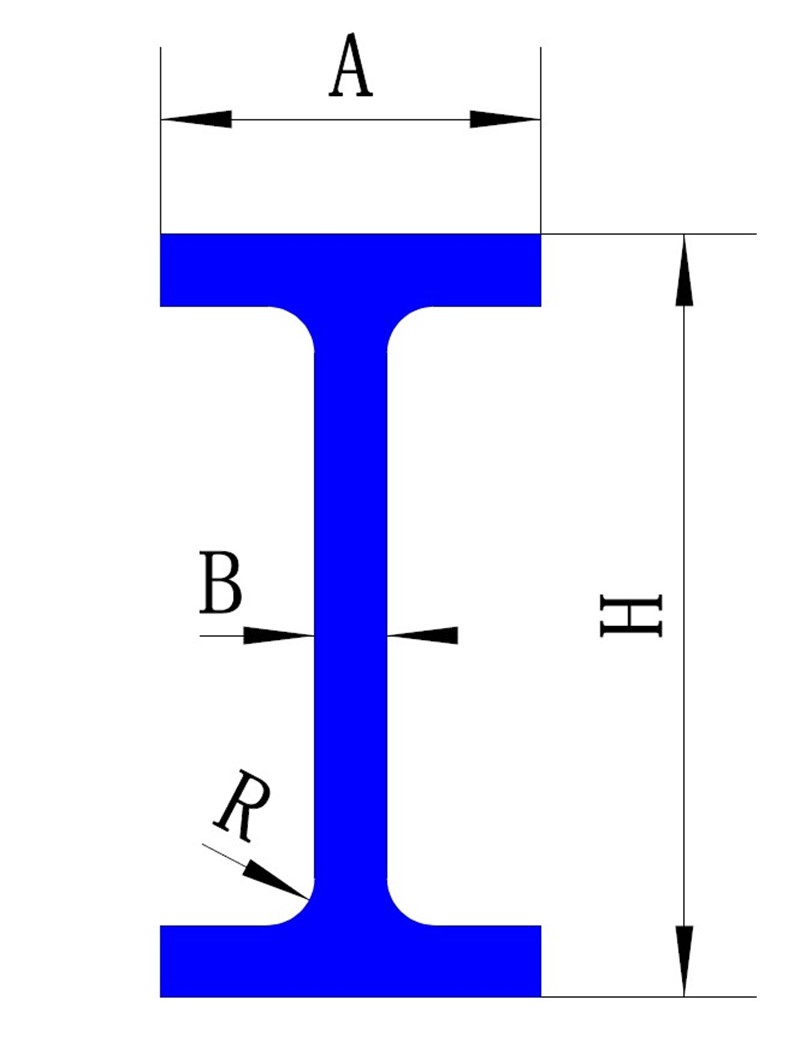

hydraulic check valve

Applications of Hydraulic Check Valves

Hydraulic check valves have a wide range of applications across various industries, including

- Oil and Gas In this sector, check valves ensure the safe transport of oil and gas, preventing backflow that could lead to spills or system failures. - Manufacturing These valves are vital in hydraulic systems, maintaining consistent pressure and flow in machines and equipment.

- Water Treatment Check valves help maintain proper flow distribution in treatment plants, preventing contamination from backflow.

- Automotive In hydraulic braking systems, check valves enhance safety by ensuring that fluid flows in the correct direction, safeguarding against system failure.

Benefits of Hydraulic Check Valves

The installation of hydraulic check valves offers several benefits, including

- Protection They protect pumps and other sensitive equipment from potential damage due to backflow.

- Efficiency By ensuring one-way flow, check valves improve the overall efficiency of hydraulic systems.

- Reduced Maintenance Minimizing the risk of backflow reduces the likelihood of system failures and maintenance needs, promoting long-term reliability.

In conclusion, hydraulic check valves are a critical component in ensuring the proper functioning of hydraulic systems, protecting equipment, and enhancing operational efficiency. Understanding their types and applications is vital for engineers and technicians working in fluid control. As technology advances, these valves continue to evolve, providing even greater reliability and performance in diverse applications.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS