Aug . 22, 2024 02:28 Back to list

Understanding the Functionality and Applications of 4 Inch Ball Check Valves in Plumbing Systems

Understanding the 4% Ball Check Valve A Key Component in Fluid Control

When it comes to fluid management systems, the importance of reliable components cannot be overstated. Among these critical components, the ball check valve plays a pivotal role, particularly in applications requiring prevention of backflow. This article delves into the design, functionality, and applications of the ball check valve, particularly focusing on the 4% variant which highlights a common specification in the industry.

What is a Ball Check Valve?

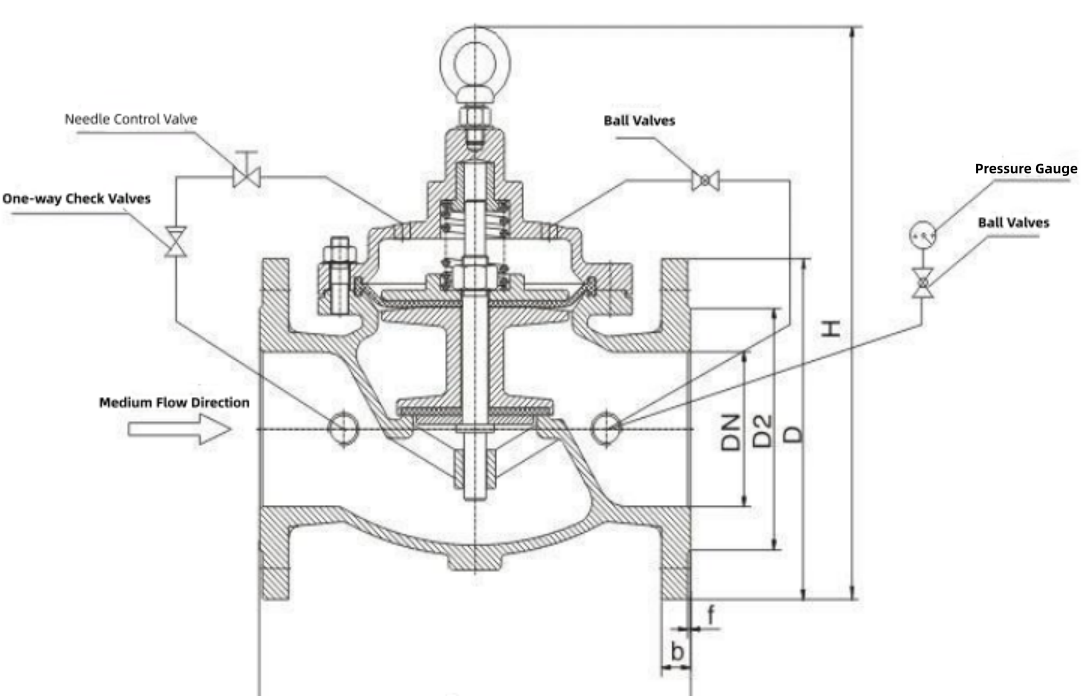

A ball check valve is a mechanical device designed to allow fluid to flow in one direction while preventing backflow. Its operation hinges on a spherical ball that seals off the flow path when there is a reverse flow. The ball is typically housed in a chamber that allows for movement, facilitated by the pressure differential between the two sides of the valve. When fluid pressure is applied in the forward direction, the ball lifts, allowing fluid to pass. Conversely, if the pressure reduces or reverses, gravity and back pressure force the ball downward into its seat, creating a seal.

Key Features of the 4% Ball Check Valve

The 4% designation often refers to specific operational characteristics or design attributes of the valve. In this context, it might represent parameters such as the valve's size, pressure rating, or its flow coefficient, contributing to its efficiency in fluid dynamics.

1. Size and Flow Capacity The size of the valve is crucial for determining the flow rate it can handle. A 4% ball check valve typically allows for a considerable flow capacity, making it suitable for various industrial applications.

2. Material Construction Ball check valves can be constructed from various materials including stainless steel, brass, and plastic, selected based on the fluid's chemistry, pressure, and temperature requirements. The material affects durability, maintenance, and longevity in service.

4 ball check valve

3. Pressure and Temperature Ratings A significant aspect of the 4% ball check valve is its pressure and temperature ratings, which define the operating conditions under which the valve can perform efficiently without risk of failure.

Applications of the 4% Ball Check Valve

Ball check valves are integral components in numerous industries, including water treatment, chemical processing, and HVAC systems. Their primary applications include

- Preventing Backflow in Pipelines In water supply systems, the valve serves to prevent contaminated water from flowing back into clean water lines, thereby protecting public health. - Sump Pumps and Drainage Systems In sump pump systems, these valves help to ensure that water does not flow back into the sump, maximizing efficiency in drainage processes.

- Process Industries In chemical processing, preventing backflow protects sensitive processes and equipment from contamination and damage.

- Fire Protection Systems In fire protection systems, ball check valves are used to ensure that water or fire suppressants flow in the correct direction, safeguarding against system malfunctions during emergencies.

Conclusion

The 4% ball check valve is an essential component in fluid control systems, offering reliability and efficiency in preventing backflow. With its unique design and robust functionality, it finds applications across various industries, contributing to the safe and effective management of fluids. As technology advances, innovations in valve design promise improved performance, enhancing our ability to maintain control over fluid systems in an increasingly complex industrial landscape. Understanding the role and specifications of these valves is critical for engineers and operators alike, ensuring optimal system functionality and longevity. By investing in quality components like the 4% ball check valve, industries can reduce operational risks and improve efficiency in their fluid management processes.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS