Jul . 26, 2024 09:31 Back to list

Understanding the Functionality and Applications of 1% 202% Gate Valves in Industrial Settings

Understanding the 1% - 2% in Gate Valve Performance and Design

Gate valves are critical components in various industrial applications, especially in the oil and gas, water treatment, and chemical processing sectors. They are designed to provide a straight-line flow path and are typically used to either fully open or fully close a pipeline. The performance of gate valves can often be quantitatively assessed by parameters such as flow coefficients and pressure allowances, and an increasingly important consideration in valve design and selection is the 1% - 2% specification standard.

The Principle of Gate Valves

Gate valves operate by using a gate (or wedge) that moves up and down between two seats to control the flow of fluid. When the valve is fully opened, the gate is raised completely, allowing for minimal resistance and turbulence in the flow path. Conversely, when the valve is closed, the gate descends into the flow path, creating a seal against the seats to prevent any fluid passage. This mechanism is vital for processes requiring control over flow rates, shutdowns, and maintenance operations.

1% - 2% Specification

In the context of gate valves, the 1% - 2% specification often refers to the allowable flow variation or the tolerance in the design and installation of valves. Specifically, this means that the flow rate through the valve can deviate by 1% to 2% from the nominal value under standard operating conditions. These tolerances are critical for applications where accurate flow control is paramount.

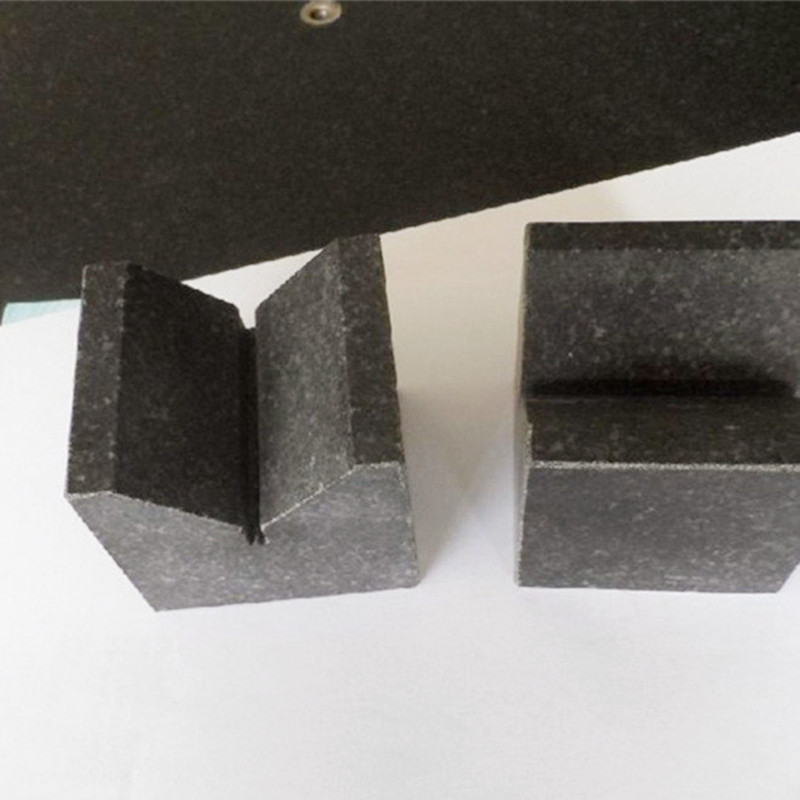

1 2 in gate valve

For example, in a critical system supplying water to a municipal facility, an unexpected variance in flow can lead to pressure fluctuations and potentially affect the overall system functionality. The 1% - 2% tolerance ensures that gate valves are designed and calibrated to maintain precise control of flow, contributing to the reliability and safety of the system.

Design Considerations

When designing gate valves according to the 1% - 2% tolerance standard, engineers must take several factors into account, including material selection, valve size, and sealing mechanism. The materials must be durable and capable of withstanding high pressures and temperatures, which are common in many industrial applications. Furthermore, the size of the valve must be appropriately selected to match the pipeline specifications and flow requirements.

The actuating mechanism of the gate valve is also pivotal in maintaining flow accuracy. Manual, electric, or pneumatic actuators can provide varying levels of control and response time, impacting how closely the valve can adhere to the desired flow rate. This choice contributes directly to the 1% - 2% performance standard, thereby influencing the valve's efficiency and reliability.

Conclusion

The incorporation of a 1% - 2% specification into the performance evaluation and design of gate valves reflects a growing awareness of the need for precision in industrial fluid control systems. As industries strive for efficiency and safety, these specifications assist engineers and operators in selecting and maintaining the right valves for their applications. Understanding these tolerances not only improves operational performance but also enhances the longevity and reliability of the systems in which these valves are employed. Ensuring compliance with such standards is essential for industries that depend heavily on precise fluid dynamics, ultimately contributing to better resource management and operational effectiveness.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS