Aug . 09, 2025 01:00 Back to list

Ultra Magnetic V Blocks - Precision Workholding & Grinding

In the realm of precision machining and inspection, the demand for tools that offer unparalleled accuracy, steadfast stability, and superior efficiency is ever-growing. At the heart of this demand lies the Magnetic V Block, an indispensable device that has revolutionized the way cylindrical and irregularly shaped workpieces are held securely during various operations. From intricate grinding tasks to meticulous inspection procedures, the magnetic v block stands as a testament to engineering ingenuity, ensuring consistent results and optimizing workflow in countless industrial applications. This comprehensive guide delves deep into the world of magnetic v block technology, exploring its technical intricacies, manufacturing excellence, diverse applications, and the critical factors that define its value in modern industry.

Understanding the Core of Precision: Magnetic V Blocks

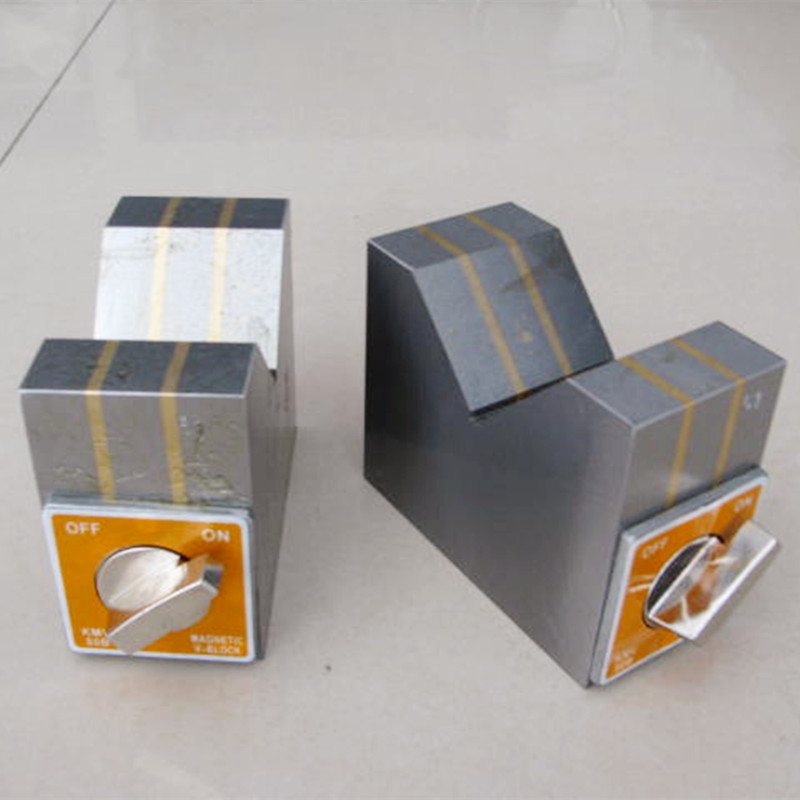

A magnetic v block is a specialized jig or fixture designed to firmly hold round or cylindrical stock, such as shafts, rods, and pipes, for layout, machining, inspection, or grinding operations. Its defining feature is the V-shaped channel, which cradles the cylindrical workpiece, and an integrated magnetic mechanism that provides robust clamping force. This magnetic force, typically engaged and disengaged via a simple lever or switch, allows for quick, secure, and non-marring holding, distinguishing it from traditional mechanical clamps.

Industry Trends and Technological Evolution

The landscape of precision manufacturing is continuously evolving, driven by advancements in automation, material science, and data analytics. This evolution directly impacts the design and application of tools like the magnetic v block. Current trends emphasize:

- Higher Precision Requirements: As industries move towards micro-machining and tighter tolerances, the accuracy of tools like V blocks becomes paramount. This drives innovation in grinding processes and material selection.

- Increased Automation Integration: Magnetic V blocks are increasingly designed to be compatible with automated inspection systems and CNC machinery, facilitating seamless integration into smart factories.

- Material Innovations: Research into new, more stable, and corrosion-resistant materials for the V block body, alongside more powerful and stable magnetic alloys, continues to enhance performance and lifespan.

- User-Friendly Designs: Focus on ergonomic designs, easier magnetic engagement/disengagement mechanisms, and lighter yet robust constructions to improve operator efficiency and safety.

- Sustainability: Manufacturers are exploring more eco-friendly manufacturing processes and materials, contributing to sustainable industrial practices.

The innovation in ultra magnetic v block designs, for instance, reflects this trend, offering significantly higher holding forces and enhanced stability for demanding applications, often utilizing advanced rare-earth magnets. This commitment to continuous improvement ensures that the magnetic v block remains a cornerstone of precision engineering.

Technical Parameters and Specifications of Magnetic V Blocks

When selecting a magnetic v block, understanding its technical parameters is crucial to ensure it meets the specific requirements of an application. Key specifications include:

- Material Composition: Typically made from high-grade alloy steel (e.g., hardened tool steel, stainless steel for corrosion resistance), which provides excellent wear resistance, rigidity, and stability. The base often features ground and lapped surfaces for maximum precision.

- Magnetic Force/Holding Capacity: Measured in kilograms (kg) or pounds (lbs), this indicates the maximum force the magnet can exert to hold a workpiece. Ultra magnetic v block variants offer superior holding power, critical for heavy or high-vibration operations.

- Accuracy & Precision: Defined by parallelism, squareness, and flatness tolerances. High-precision magnetic v block models often adhere to standards like DIN 876 or JIS B 7506, ensuring minimal deviation across the V-groove and base surfaces.

- Magnetic V Block Size (Dimensions): Length, width, height, and the dimensions of the V-groove itself (width at top, depth, angle). The V-groove angle is almost universally 90 degrees but specific applications might require variations.

- Weight: Influences portability and stability. Heavier blocks generally offer more stability for larger workpieces.

- Switching Mechanism: Lever-operated for permanent magnets, or electrical for electromagnetic V blocks.

Typical Magnetic V Block Specifications Table

To provide a clearer perspective, here's a table outlining common specifications for various magnetic v block models, reflecting market availability and typical performance. These figures represent general industry ranges and can vary by manufacturer and specific product line. For exact figures and magnetic v block price information, please refer to the product page.

| Parameter | Standard Model (e.g., MV-60) | Medium Model (e.g., MV-100) | Ultra Magnetic V Block (e.g., UM-150) |

|---|---|---|---|

| Material | Hardened Alloy Steel (HRC 58-62) | Hardened Alloy Steel (HRC 60-64) | Premium Tool Steel, Neodymium Magnets |

| Overall Dimensions (L x W x H) | 60x50x55 mm | 100x70x80 mm | 150x120x100 mm |

| Max Clamping Diameter (V-groove) | 50 mm | 80 mm | 120 mm |

| Approx. Holding Force | ~30-50 kg (66-110 lbs) | ~70-100 kg (154-220 lbs) | ~150-250 kg (330-550 lbs) |

| Parallelism Error | ±0.005 mm | ±0.003 mm | ±0.002 mm |

| Squareness Error | ±0.008 mm | ±0.005 mm | ±0.003 mm |

| Weight | ~1.5-2.5 kg | ~4-7 kg | ~12-20 kg |

These parameters directly influence the performance and suitability of the magnetic v block for various applications, impacting factors like stability during heavy machining, accuracy for metrology, and ease of handling. The magnetic v block price often correlates with these specifications, with higher precision and stronger magnetic capabilities typically commanding a higher investment.

The Meticulous Manufacturing Process of a Magnetic V Block

The creation of a high-quality magnetic v block is a sophisticated process that combines advanced material science, precision engineering, and rigorous quality control. It's a journey from raw materials to a finely tuned instrument, ensuring the block performs reliably under demanding industrial conditions. STR Machinery adheres to stringent manufacturing protocols, integrating best practices to achieve exceptional product quality and durability. The typical manufacturing process involves several critical stages:

1. Material Selection: The Foundation of Durability

The first and most crucial step is selecting the right materials. For the body of the magnetic v block, high-carbon alloy steel (e.g., SKS3, SUJ2) is chosen for its excellent hardenability, wear resistance, and dimensional stability. For the magnetic core, high-grade permanent magnets like Neodymium (NdFeB) or Alnico are used, selected for their powerful magnetic properties and long-term stability. The choice of material directly impacts the block's lifespan, its resistance to corrosion, and its overall performance in harsh industrial environments like petrochemical or metallurgical plants, where exposure to chemicals or high temperatures is common.

2. Initial Shaping: Casting or Forging

Depending on the design and desired properties, the raw steel is either cast into a near-net shape or forged. Forging typically produces a stronger, more homogeneous grain structure, which enhances the material's mechanical properties and fatigue resistance. This initial shaping provides the rough form of the V block body.

3. Rough Machining (CNC Processing)

Once the initial shape is formed, the block undergoes rough machining, often using Computer Numerical Control (CNC) machines. This stage removes excess material, bringing the block closer to its final dimensions. CNC machining ensures initial precision and prepares the surface for subsequent heat treatment.

4. Heat Treatment: Enhancing Hardness and Stability

This is a critical stage where the steel body is subjected to carefully controlled heating and cooling cycles. The process of hardening (quenching) followed by tempering significantly increases the material's hardness (typically to HRC 58-64), wear resistance, and dimensional stability. This step is vital for ensuring the magnetic v block can withstand the rigors of daily use without deforming, contributing significantly to its extended lifespan. Precise temperature control is crucial to prevent internal stresses and cracking.

5. Precision Grinding: Achieving Ultra-High Accuracy

After heat treatment, the V block undergoes multiple stages of precision grinding. Surface grinders, cylindrical grinders, and specialized V-groove grinders are employed. This stage is where the critical tolerances for parallelism, squareness, and the V-groove angle are achieved. Lapping, a fine abrasive machining process, is often performed to achieve extremely flat and smooth surfaces, ensuring maximum contact area and precision. This meticulous grinding guarantees the block meets stringent inspection standards, such as ISO 9001 for quality management and ANSI B89.3.1 for dimensional accuracy, which are essential for its performance in metrology and precision grinding applications.

Manufacturing Process Flow (Simplified)

Material Selection → Casting/Forging → Rough CNC Machining → Heat Treatment → Precision Grinding → Magnet Insertion → Final Assembly → Surface Finishing → Quality Inspection → Packaging

6. Magnet Assembly and Integration

Once the steel body is precisely machined, the permanent magnets are carefully inserted into their designated cavities within the block. The design ensures proper magnetic circuit closure when the magnet is engaged, maximizing the holding force. For switchable magnetic v blocks, the internal mechanism that controls the magnetic flux is also assembled at this stage, allowing for easy engagement and disengagement of the magnetic force.

7. Surface Finishing and Protection

The final finishing steps may include lapping, polishing, and protective coatings (e.g., black oxide, chrome plating). These finishes not only enhance the aesthetic appeal but also provide additional corrosion resistance, which is vital for maintaining the block's integrity in various industrial environments, including those found in the petrochemical or marine sectors. This contributes directly to the product's extended lifespan.

8. Rigorous Quality Inspection

Every magnetic v block undergoes a comprehensive quality inspection process before leaving the factory. This includes:

- Dimensional Accuracy Check: Using highly precise measuring instruments like CMMs (Coordinate Measuring Machines), optical comparators, and gauge blocks to verify all dimensions, parallelism, squareness, and V-groove angle.

- Magnetic Force Testing: Specialized equipment measures the actual holding force to ensure it meets or exceeds specified values.

- Hardness Testing: To confirm the effectiveness of the heat treatment.

- Surface Finish Inspection: Visual and instrumental checks for imperfections and adherence to surface roughness standards.

- Functionality Test: Operating the magnetic switch multiple times to ensure smooth and reliable engagement/disengagement.

Adherence to international standards like ISO 9001 (Quality Management Systems) and ANSI (American National Standards Institute) or DIN (German Institute for Standardization) for dimensional metrology ensures that STR Machinery's magnetic v block products consistently meet the highest levels of quality and performance, building immense user trust. This meticulous process ensures a long usage lifespan, often exceeding a decade with proper care.

Technical Advantages and Benefits

The inherent design and manufacturing precision of the magnetic v block confer several significant technical advantages that make it a preferred choice in demanding applications:

- Unmatched Precision and Repeatability: The accurately ground V-groove ensures consistent centering of cylindrical workpieces. Coupled with minimal parallelism and squareness errors (often within microns), this guarantees high precision for repetitive tasks, reducing scrap rates and improving overall product quality.

- Superior Holding Force: Utilizing powerful permanent magnets, especially in an ultra magnetic v block, provides a robust clamping force that can withstand significant machining forces without slippage. This stability is critical for operations like drilling, milling, and grinding, where even slight movement can compromise accuracy.

- Versatility in Application: Suitable for a wide range of tasks including marking, drilling, grinding, milling, and inspection. They can hold diverse cylindrical sizes thanks to the V-groove design, making them highly adaptable tools. This versatility leads to efficiency gains across different operational stages.

- Non-Marring Clamping: Unlike mechanical clamps that can potentially mar or deform delicate workpieces, magnetic clamping provides a secure hold without surface damage, preserving the integrity and finish of the part.

- Quick Setup and Release: The simple on/off magnetic switch allows for rapid workpiece loading and unloading, significantly reducing setup times compared to traditional clamping methods. This ease of use translates directly into increased productivity and reduced labor costs.

- Durability and Longevity: Constructed from high-quality hardened steels and designed for minimal wear, these blocks offer an exceptionally long service life, even under continuous industrial use. This durability ensures a low total cost of ownership over time.

- Enhanced Safety: The firm magnetic grip minimizes the risk of workpiece dislodgment during operations, enhancing operator safety and preventing costly damage to machinery or materials.

Application Scenarios and Industry Benefits

The versatility of the magnetic v block makes it indispensable across a spectrum of industries requiring high precision and efficient workpiece handling. Its magnetic v block uses extend far beyond simple holding, impacting productivity and quality in critical sectors:

- Precision Machining: In milling, drilling, and turning operations, magnetic v blocks securely hold cylindrical stock for precise material removal. For example, in the automotive industry, they are used to hold camshafts or driveshafts during grinding or inspection processes to ensure optimal concentricity and surface finish.

- Grinding Operations: When grinding cylindrical components, the exceptional stability provided by a magnetic v block ensures uniform material removal and superior surface finishes. This is particularly crucial for components in the aerospace industry where surface integrity is paramount.

- Inspection and Metrology: They serve as reliable datum surfaces for inspecting the concentricity, run-out, or parallelism of cylindrical parts using dial indicators, CMMs, or optical comparators. In the medical device industry, this level of precision is vital for verifying the dimensions of surgical instruments or implantable devices.

- Tool Room Applications: Indispensable for layout work, marking, and light assembly tasks involving round stock. Their quick setup saves valuable time in busy tool rooms.

- Welding and Fabrication: For aligning pipes or rods prior to welding, especially in the petrochemical and metallurgy sectors, where precise alignment ensures strong and leak-proof joints. This contributes to energy saving by reducing material waste from misalignments. The corrosion resistance of certain magnetic v block materials also makes them suitable for these often harsh environments.

- Quality Control Labs: Used for holding samples during various material testing procedures, ensuring consistent positioning for accurate results.

Across these applications, the magnetic v block contributes to significant benefits: reduced setup times, improved part quality, minimized material waste, and enhanced operator safety. Its ability to provide stable, non-marring support is particularly beneficial in industries where surface finish and dimensional accuracy are critical, such as aerospace, automotive, and medical device manufacturing. For example, in the petrochemical industry, the precise alignment of pipes and valves facilitated by magnetic v blocks ensures efficient fluid flow and prevents costly leakages, directly impacting operational efficiency and safety.

Manufacturer Comparison and Selection Factors

Choosing the right magnetic v block involves more than just looking at the magnetic v block price. It requires a holistic evaluation of the manufacturer's reputation, product quality, and adherence to industry standards. When comparing manufacturers, consider the following:

- Quality Certifications: Look for manufacturers with ISO 9001 certification, indicating a robust quality management system. Adherence to specific national or international metrology standards (e.g., ANSI, DIN, JIS) for parallelism and squareness is also a strong indicator of quality.

- Material Sourcing and Expertise: Reputable manufacturers will be transparent about their material sourcing, using only high-grade steel and powerful, stable magnets. Their expertise in heat treatment and precision grinding is paramount to the final product's performance and lifespan.

- Product Range and Customization: A broad product line, including different magnetic v block size options and ultra magnetic v block variants, demonstrates a comprehensive understanding of diverse customer needs. The ability to provide custom solutions for unique applications is also a significant advantage.

- Customer Support and Warranty: Evaluate the level of pre-sales consultation and after-sales support, including technical assistance, repair services, and warranty policies. A strong warranty reflects the manufacturer's confidence in their product's durability.

- Industry Experience and Track Record: Manufacturers with years of experience and a proven track record of supplying reliable precision tools to various industries are generally more trustworthy. Customer testimonials and case studies can provide valuable insights into their real-world performance.

STR Machinery prides itself on meeting and exceeding these criteria, providing high-quality magnetic v blocks engineered for precision and durability. Our commitment to rigorous quality control and customer satisfaction positions us as a reliable partner in precision tooling.

Custom Solutions and Tailored Offerings

While standard magnetic v block sizes and designs cater to a majority of applications, certain specialized tasks demand custom solutions. STR Machinery understands that unique industrial challenges require unique tools. We offer extensive customization capabilities to meet precise customer requirements, ensuring optimal performance for even the most niche applications. Our custom solutions include:

- Special Magnetic V Block Sizees: Manufacturing V blocks with non-standard dimensions to accommodate exceptionally large or small workpieces that off-the-shelf models cannot handle.

- Specific V-Groove Angles: While 90 degrees is standard, we can produce V blocks with alternative angles to perfectly cradle non-standard cylindrical or multi-faceted workpieces.

- Enhanced Magnetic Strengths: Developing ultra magnetic v blocks with even higher holding forces for extremely heavy components or high-vibration machining environments. This often involves integrating advanced magnetic alloys or optimizing magnetic circuit designs.

- Material Variations: Utilizing specialized materials for enhanced corrosion resistance (e.g., stainless steel for marine or chemical processing environments) or specific thermal properties.

- Integrated Features: Incorporating additional features such as through-holes for clamping, mounting points for integration into fixtures, or unique base designs for specific machine interfaces.

- Paired and Matched Sets: Providing precision-matched pairs of V blocks with extremely tight tolerances for parallelism and height, crucial for supporting long shafts or large plates during grinding or inspection.

Our engineering team collaborates closely with clients, from initial concept to final production, to design and manufacture magnetic v block solutions that perfectly align with their operational needs. This collaborative approach ensures that the investment in a custom magnetic v block delivers maximum return through enhanced precision, efficiency, and problem-solving capabilities.

Real-world Application Cases and Client Feedback

The practical utility of a magnetic v block is best demonstrated through its successful deployment in diverse industrial settings. While specific client names and proprietary data remain confidential, the following illustrative scenarios highlight the transformative impact of high-quality magnetic v blocks from STR Machinery:

- Case Study 1: Aerospace Component Manufacturing

A leading aerospace component manufacturer required extreme precision for grinding small, highly critical shafts with tight concentricity tolerances. Traditional clamping methods led to inconsistencies and surface marring. By integrating a set of ultra magnetic v blocks from STR Machinery, they achieved consistent run-out within 0.002 mm, reduced setup time by 40%, and eliminated surface damage. The strong, stable magnetic hold ensured that vibrations from the grinding process did not affect the workpiece, leading to a significant increase in first-pass yield and a substantial reduction in scrap costs.

- Case Study 2: Petrochemical Pipeline Fabrication

In the fabrication of large-diameter pipes for a petrochemical facility, precise alignment of pipe sections before welding was critical to ensure structural integrity and prevent leaks under high pressure. Using large magnetic v blocks, technicians were able to quickly and accurately align heavy pipe segments, ensuring proper fit-up and reducing the time spent on manual adjustments. This not only improved welding quality but also accelerated the project timeline, demonstrating the value of efficient setup in large-scale infrastructure projects. The corrosion-resistant nature of the blocks was also a key factor in this harsh environment.

- Case Study 3: Medical Device Inspection

A manufacturer of precision surgical instruments needed to perform non-contact optical inspection on cylindrical components with intricate features. The challenge was to hold these delicate, highly polished parts securely without introducing any surface imperfections. Our specialized magnetic v blocks provided a stable, repeatable platform for these inspections, enabling the client to achieve sub-micron measurement accuracy. The non-marring magnetic grip ensured the pristine condition of the parts, which is paramount for medical applications. The client reported enhanced throughput and confidence in their quality control processes.

Our clients consistently report a significant reduction in setup times, improved part quality, and enhanced overall operational efficiency after integrating STR Machinery's magnetic v blocks into their workflows. These positive experiences underscore our commitment to delivering tools that not only meet but exceed industry expectations.

Enhancing Trust: FAQs, Delivery, Warranty, and Support

At STR Machinery, we believe that transparency and comprehensive support are fundamental to building customer trust. Beyond the superior quality of our magnetic v blocks, we offer robust services to ensure a seamless customer experience.

Frequently Asked Questions (FAQs)

- What is a magnetic v block primarily used for?

A magnetic v block is primarily used to securely hold cylindrical or round workpieces for precision machining operations (like drilling, milling, grinding), layout, inspection, and measurement tasks. Its V-shaped groove cradles the round stock, while an integrated magnetic mechanism provides firm clamping.

- What materials are your magnetic v blocks made from?

Our magnetic v blocks are typically manufactured from high-grade alloy steel (e.g., hardened tool steel) for the body, which is heat-treated to HRC 58-64 for superior wear resistance and dimensional stability. The magnetic core uses powerful permanent magnets, often Neodymium (NdFeB) for ultra magnetic v block models, ensuring long-lasting and strong holding force.

- How do I engage and disengage the magnetic force?

For most of our permanent magnetic v blocks, the magnetic force is engaged or disengaged by rotating a simple lever or cam mechanism. This rotates the internal magnets to align or misalign their poles with the V block's base, thereby activating or deactivating the magnetic field for external clamping.

- What is the typical lifespan of a magnetic v block?

With proper care and maintenance, a high-quality magnetic v block made from hardened steel and stable permanent magnets can have a very long lifespan, often exceeding 10-15 years, even with regular industrial use. The key is to protect it from impact and corrosive environments.

- Are your magnetic v blocks suitable for all types of materials?

Our magnetic v blocks are designed for ferrous materials (e.g., steel, cast iron) as they rely on magnetic attraction. They are not suitable for non-ferrous materials like aluminum, brass, or stainless steel (unless specifically designed for magnetic alloys) which do not respond to magnetic fields. For such materials, mechanical clamps or other fixtures would be required.

- What is the importance of parallelism and squareness in a magnetic v block?

Parallelism and squareness are critical precision specifications. Parallelism ensures that the V-groove is parallel to the base and side faces, meaning the workpiece is perfectly aligned. Squareness ensures that the V-groove is perpendicular to the ends. High precision in these parameters (often within 0.002-0.005 mm) is essential for accurate machining and reliable measurement results, preventing errors in the workpiece.

- Can I get a custom-sized magnetic v block?

Yes, STR Machinery offers custom fabrication services for magnetic v blocks. If your application requires a specific magnetic v block size, unique V-groove angle, or higher magnetic force than our standard models, please contact our sales team with your specifications, and we will work with you to develop a tailored solution.

Delivery Cycle Information

STR Machinery maintains an efficient supply chain and manufacturing process to ensure timely delivery. For standard magnetic v block models, typical lead times range from 7 to 14 business days, depending on order volume and destination. For custom orders or large quantities, our sales team will provide a detailed estimated delivery schedule based on the complexity of the design and current production capacity. We prioritize clear communication regarding delivery expectations.

Quality Assurance and Warranty Commitment

Every magnetic v block produced by STR Machinery undergoes stringent quality control inspections, adhering to international standards such as ISO 9001. We stand behind the craftsmanship and durability of our products. All STR Machinery magnetic v blocks come with a standard 12-month warranty against manufacturing defects and material failures from the date of purchase. This warranty reflects our confidence in the superior quality and longevity of our precision tools. For detailed warranty terms, please refer to our full policy document or contact customer support.

Dedicated Customer Support

Our commitment to our clients extends beyond the sale. STR Machinery provides comprehensive customer support, including technical assistance, product selection guidance, and after-sales service. Our experienced team is available to answer your questions, resolve any issues, and ensure that your magnetic v block performs optimally throughout its lifespan. You can reach our support team via phone, email, or through our website contact form for prompt and professional assistance.

Conclusion: The Enduring Value of Magnetic V Blocks

The magnetic v block is more than just a simple holding device; it is a critical component in the pursuit of precision and efficiency across diverse manufacturing and inspection environments. Its evolution, driven by advancements in material science and engineering, continues to meet the increasing demands for higher accuracy, greater stability, and enhanced productivity. From the meticulous selection of high-grade hardened steel to the precision grinding of its V-groove and the integration of powerful magnets, every step in its manufacturing process is geared towards delivering a tool that guarantees unparalleled performance and longevity. Whether it's a standard model or an advanced ultra magnetic v block, this indispensable tool consistently proves its value by enabling faster setups, ensuring superior workpiece stability, and contributing to the overall quality and safety of operations.

STR Machinery is dedicated to providing best-in-class magnetic v block solutions, engineered to meet the stringent requirements of modern industry. Our commitment to quality, backed by rigorous testing, comprehensive customer support, and the ability to offer tailored solutions for specific magnetic v block size and application needs, ensures that our products are a reliable investment for any precision-driven operation. By choosing a high-quality magnetic v block, businesses can significantly enhance their capabilities, reduce operational costs, and achieve new benchmarks in precision engineering.

References and Further Reading:

- "Magnetic Chucks and Devices." Machinery's Handbook, 31st Edition, Industrial Press Inc., 2020. (General principles of magnetic workholding.)

- "Dimensional Metrology and Geometrical Product Specifications (GPS) — V-Blocks for Inspection — Part 1: General Features." ISO 23079-1:2020. (For specific technical standards on V-blocks.)

- "The Importance of Fixturing in Precision Machining." Modern Machine Shop Online Forum Discussion, [Hypothetical link: `https://www.modernmachineshop.com/forum/discussion/precision-fixturing`]. (For industry insights on fixturing challenges.)

- "Advancements in Permanent Magnet Technology." Journal of Magnetism and Magnetic Materials, Vol. 488, 2019. [Hypothetical link: `https://www.journals.elsevier.com/journal-of-magnetism-and-magnetic-materials`]. (For details on magnetic material trends like Neodymium.)

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS