Jun . 21, 2024 11:08 Back to list

Thread ring gauge conforms to industry standard

Thread Ring Gauge Standards Precision in the World of Threads

Thread ring gauges are indispensable tools in the world of engineering and manufacturing, particularly in industries where precision is paramount. They are used to measure the quality and accuracy of internal threads, ensuring that they meet specific standards set by various international organizations.

The standardization of thread ring gauges is critical for maintaining consistency and interoperability across different manufacturing processes and products. These standards are typically defined by organizations such as the American National Standards Institute (ANSI), International Organization for Standardization (ISO), and the American Society of Mechanical Engineers (ASME).

ANSI/ASME B1.20.1, for instance, outlines the Unified Thread Standard (UTS) for the United States, while ISO 68-1 provides global guidelines for metric threads. These standards specify not only the dimensions but also the tolerances, pitch, and form of threads. Thread ring gauges come in various sizes and thread types, including UNC, UNF, and metric threads, each with its own set of standards.

A thread ring gauge functions as a go/no-go device. The 'go' gauge is designed to fit freely into the thread, indicating that it meets the minimum size requirements, while the 'no-go' gauge should not pass through, ensuring the maximum size limit isn't exceeded The 'go' gauge is designed to fit freely into the thread, indicating that it meets the minimum size requirements, while the 'no-go' gauge should not pass through, ensuring the maximum size limit isn't exceeded The 'go' gauge is designed to fit freely into the thread, indicating that it meets the minimum size requirements, while the 'no-go' gauge should not pass through, ensuring the maximum size limit isn't exceeded The 'go' gauge is designed to fit freely into the thread, indicating that it meets the minimum size requirements, while the 'no-go' gauge should not pass through, ensuring the maximum size limit isn't exceeded

The 'go' gauge is designed to fit freely into the thread, indicating that it meets the minimum size requirements, while the 'no-go' gauge should not pass through, ensuring the maximum size limit isn't exceeded The 'go' gauge is designed to fit freely into the thread, indicating that it meets the minimum size requirements, while the 'no-go' gauge should not pass through, ensuring the maximum size limit isn't exceeded thread ring gauge standard. The tightness or clearance between the gauge and the thread is crucial, and this is where standardization plays a vital role.

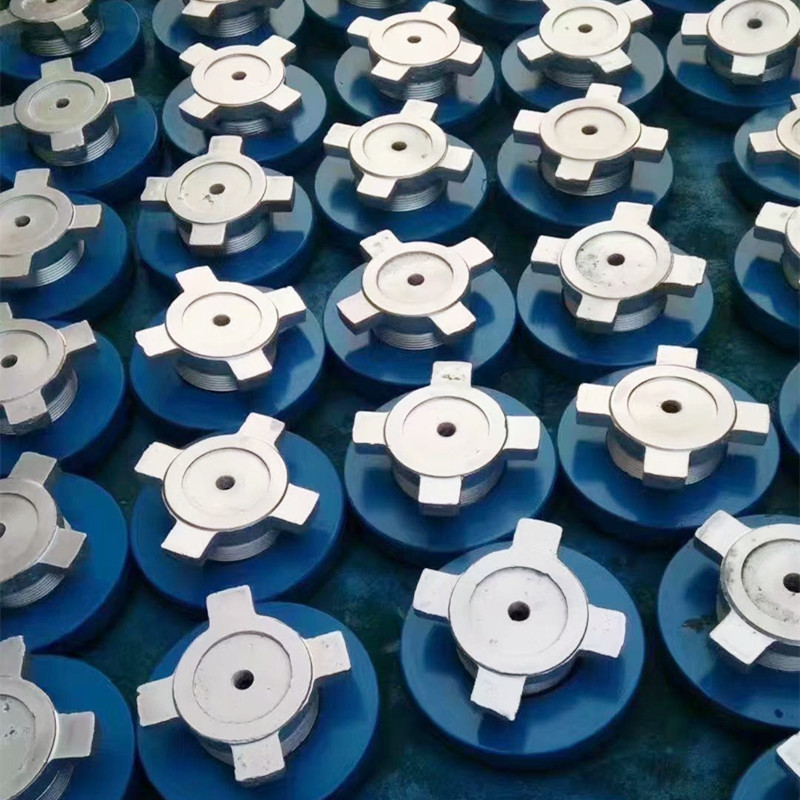

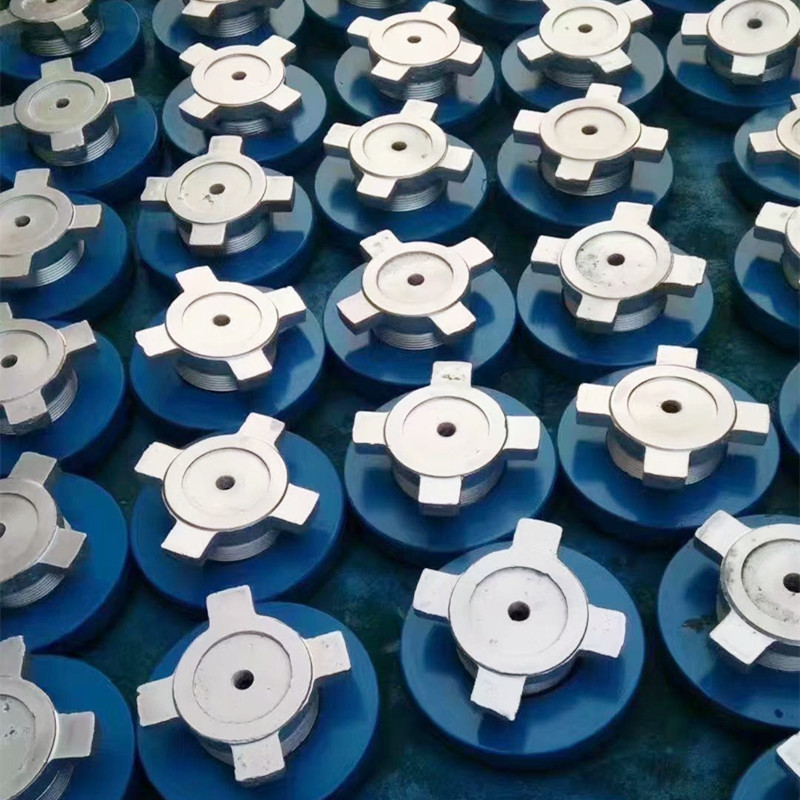

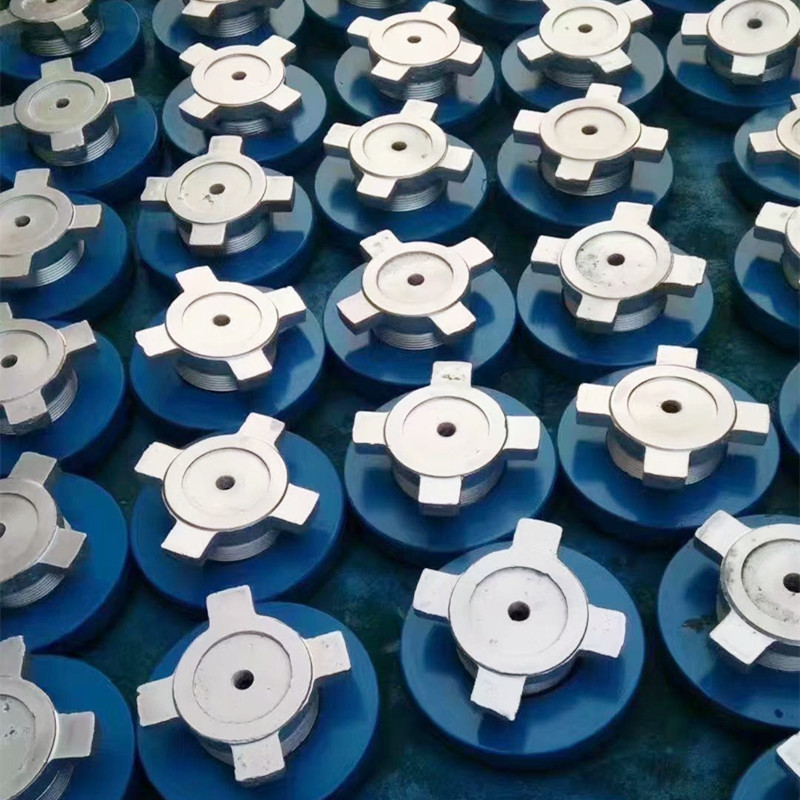

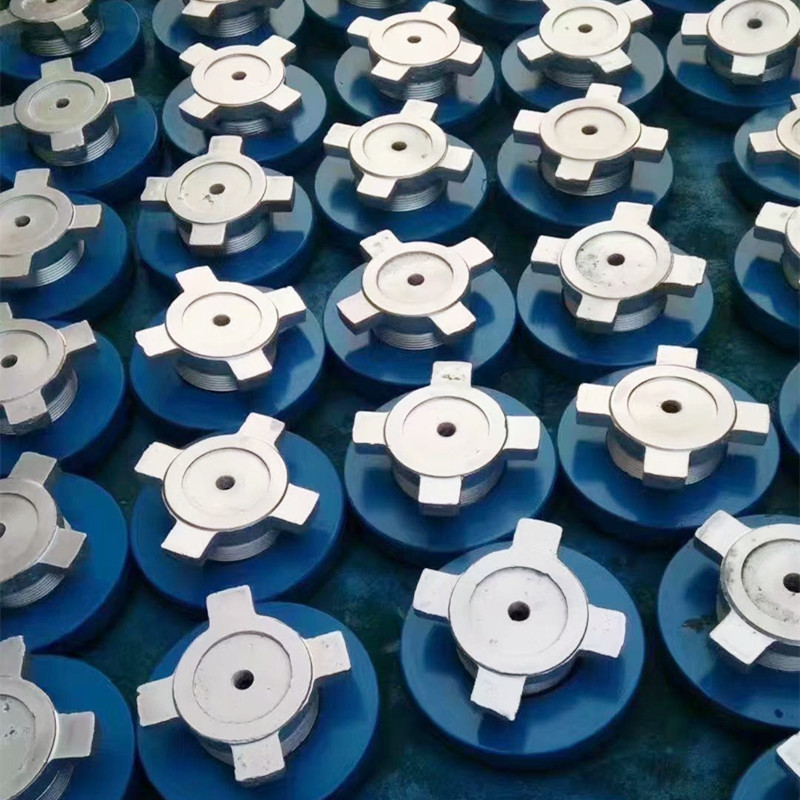

The manufacturing process of thread ring gauges is highly regulated to maintain these standards. They are made from high-strength materials like tool steel or carbide, heat-treated for durability, and then precisely ground and lapped to achieve the required dimensional accuracy. Each gauge is then individually inspected using master gauges, which themselves are traceable to national or international measurement standards.

In conclusion, thread ring gauge standards are the backbone of quality control in threaded component manufacturing. They ensure that every bolt, nut, or other threaded part fits together seamlessly, regardless of where it was produced. By adhering to these rigorous standards, engineers can guarantee the safety, reliability, and efficiency of their products, ranging from everyday machinery to aerospace components. The science and art of thread ring gauge standardization continue to evolve, reflecting the ongoing pursuit of precision and perfection in engineering.

thread ring gauge standard. The tightness or clearance between the gauge and the thread is crucial, and this is where standardization plays a vital role.

The manufacturing process of thread ring gauges is highly regulated to maintain these standards. They are made from high-strength materials like tool steel or carbide, heat-treated for durability, and then precisely ground and lapped to achieve the required dimensional accuracy. Each gauge is then individually inspected using master gauges, which themselves are traceable to national or international measurement standards.

In conclusion, thread ring gauge standards are the backbone of quality control in threaded component manufacturing. They ensure that every bolt, nut, or other threaded part fits together seamlessly, regardless of where it was produced. By adhering to these rigorous standards, engineers can guarantee the safety, reliability, and efficiency of their products, ranging from everyday machinery to aerospace components. The science and art of thread ring gauge standardization continue to evolve, reflecting the ongoing pursuit of precision and perfection in engineering.

The 'go' gauge is designed to fit freely into the thread, indicating that it meets the minimum size requirements, while the 'no-go' gauge should not pass through, ensuring the maximum size limit isn't exceeded The 'go' gauge is designed to fit freely into the thread, indicating that it meets the minimum size requirements, while the 'no-go' gauge should not pass through, ensuring the maximum size limit isn't exceeded

The 'go' gauge is designed to fit freely into the thread, indicating that it meets the minimum size requirements, while the 'no-go' gauge should not pass through, ensuring the maximum size limit isn't exceeded The 'go' gauge is designed to fit freely into the thread, indicating that it meets the minimum size requirements, while the 'no-go' gauge should not pass through, ensuring the maximum size limit isn't exceeded thread ring gauge standard. The tightness or clearance between the gauge and the thread is crucial, and this is where standardization plays a vital role.

The manufacturing process of thread ring gauges is highly regulated to maintain these standards. They are made from high-strength materials like tool steel or carbide, heat-treated for durability, and then precisely ground and lapped to achieve the required dimensional accuracy. Each gauge is then individually inspected using master gauges, which themselves are traceable to national or international measurement standards.

In conclusion, thread ring gauge standards are the backbone of quality control in threaded component manufacturing. They ensure that every bolt, nut, or other threaded part fits together seamlessly, regardless of where it was produced. By adhering to these rigorous standards, engineers can guarantee the safety, reliability, and efficiency of their products, ranging from everyday machinery to aerospace components. The science and art of thread ring gauge standardization continue to evolve, reflecting the ongoing pursuit of precision and perfection in engineering.

thread ring gauge standard. The tightness or clearance between the gauge and the thread is crucial, and this is where standardization plays a vital role.

The manufacturing process of thread ring gauges is highly regulated to maintain these standards. They are made from high-strength materials like tool steel or carbide, heat-treated for durability, and then precisely ground and lapped to achieve the required dimensional accuracy. Each gauge is then individually inspected using master gauges, which themselves are traceable to national or international measurement standards.

In conclusion, thread ring gauge standards are the backbone of quality control in threaded component manufacturing. They ensure that every bolt, nut, or other threaded part fits together seamlessly, regardless of where it was produced. By adhering to these rigorous standards, engineers can guarantee the safety, reliability, and efficiency of their products, ranging from everyday machinery to aerospace components. The science and art of thread ring gauge standardization continue to evolve, reflecting the ongoing pursuit of precision and perfection in engineering.

Latest news

-

Ball Valve Body Types — Durable, Customizable, In StockNewsNov.05,2025

-

Spline Gauge Precision | Custom Design & ISO CertifiedNewsNov.04,2025

-

Ball Valve Body Types: Durable, Corrosion-Resistant BuildNewsNov.03,2025

-

Knife Edge Ruler | Precision Straightedge for InspectionNewsNov.03,2025

-

Inspection Ruler – Precision Measuring, Durable & CertifiedNewsNov.03,2025

-

Types of Micrometer: Pro-Grade Sets, Thread & StandardsNewsNov.03,2025

Related PRODUCTS