Sep . 09, 2024 09:30 Back to list

thread pin gauge

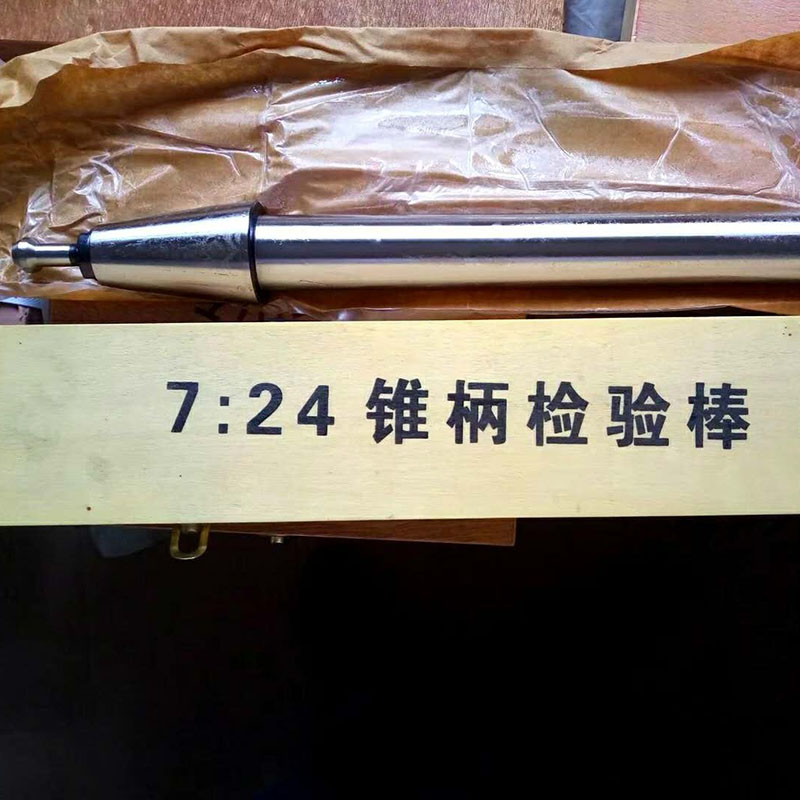

Understanding the Thread Pin Gauge An Essential Tool for Precision Measurement

In the world of manufacturing and engineering, precision is crucial. One of the tools that ensure this exactitude in measuring threaded components is the thread pin gauge. This instrument is specifically designed to assess the tolerance and quality of threaded parts, which play a vital role in everything from machinery to automotive applications.

A thread pin gauge is a simple yet effective tool used to check the accuracy of internal and external threads. It consists of a set of pins, each meticulously engineered to correspond to specific thread sizes and profiles. These gauges come in various standards, accommodating different thread types, including metric, unified, and many more. Each pin in the gauge conforms to the precise dimensions outlined in international thread standards, which dictate how threads should be formed and measured.

The primary purpose of a thread pin gauge is to ensure that the threads produced meet the required specifications

. This is critical because poorly manufactured threads can lead to mismatches during assembly, resulting in mechanical failures or compromised product integrity. Engineers and quality control professionals utilize thread pin gauges to verify the pitch, depth, and diameter of threads, guaranteeing that components will fit together correctly.thread pin gauge

Using a thread pin gauge is straightforward. The pin is inserted into the threaded hole to gauge its dimensions. If the pin fits smoothly and meets the resistance expected for that specific thread type, the dimensions are deemed acceptable. Conversely, if the pin does not fit or exhibits excessive play, it indicates that the threads fall outside the acceptable range and may require reworking or rejection.

Another critical aspect of thread pin gauges is their role in inspection and quality control processes. Manufacturers often produce a wide variety of components that require different thread types. Consequently, having a comprehensive set of thread pin gauges allows quality assurance teams to assess multiple products quickly and efficiently. This, in turn, aids in maintaining high standards, achieving customer satisfaction, and ensuring safety in applications where threaded components are crucial.

In addition to their importance in manufacturing, thread pin gauges are also valuable in maintenance and repair. Technicians use these gauges to assess the condition of existing threaded parts, determining whether they need replacement or if they can continue in service. By accurately gauging the threads, technicians can make informed decisions, extending the life of components and saving costs.

In summary, thread pin gauges are indispensable tools in the realm of precision engineering. Their simplicity and effectiveness make them vital for ensuring the quality of threaded components, which are foundational elements in countless applications. By enabling accurate measurements and adherence to standards, thread pin gauges help maintain the integrity of products, support quality assurance processes, and facilitate effective maintenance strategies. In an industry where precision is paramount, investing in high-quality thread pin gauges is essential for any organization looking to maintain competitive excellence and operational efficiency.

-

Thread Micrometer Set FeaturesNewsJul.04,2025

-

Right Angle Ruler Tool for WoodworkingNewsJul.04,2025

-

Precision Frame Level Calibration StepsNewsJul.04,2025

-

Magnetic Vee Block MaterialsNewsJul.04,2025

-

Heavy Duty Ground Anchors in MiningNewsJul.04,2025

-

Features of Welding Table Cast IronNewsJul.04,2025

Related PRODUCTS