Sep . 30, 2024 09:08 Back to list

Understanding and Utilizing Taper Ring Gauges for Precision Measurement in Engineering

Understanding Taper Ring Gauges An Essential Tool in Industry

In the world of precision engineering, the importance of accurate measurement cannot be overstated. One of the critical tools used to ensure that manufactured parts meet the required specifications is the taper ring gauge. This specialized measuring instrument plays a vital role in quality control processes across various industries, including automotive, aerospace, and manufacturing. In this article, we will explore what taper ring gauges are, their construction, how they are used, and their significance in ensuring product quality.

What is a Taper Ring Gauge?

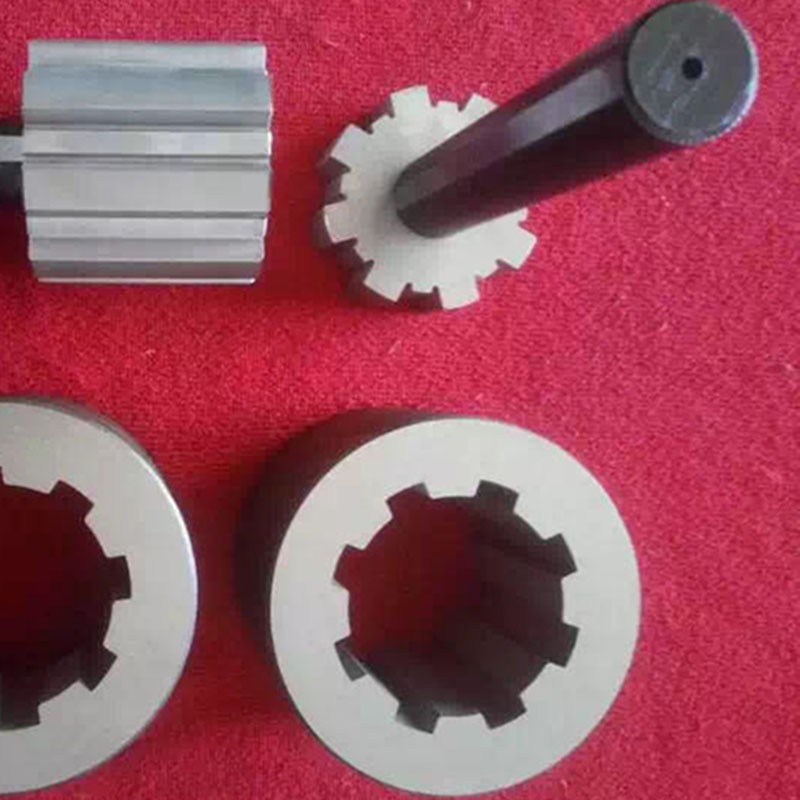

A taper ring gauge is a conical-shaped measuring tool designed to assess the diameter of a tapered hole or the external diameter of a tapered workpiece. Typically made from high-quality steel and manufactured with extreme precision, taper ring gauges come in various sizes and taper angles, allowing them to fit over or into corresponding tapered sections of machinery or equipment. Using a taper ring gauge facilitates accurate assessments of the dimensional tolerances of components, ensuring they adhere to the specified engineering standards.

Construction of Taper Ring Gauges

The construction of taper ring gauges is crucial for their functionality and accuracy. A typical taper ring gauge will have the following features

1. Material High-quality tool steel or carbide is commonly used to ensure durability and resistance to wear. 2. Taper Angle The specific angle of the taper is designed to match standard sizes, with common angles being 110, 114, or 120, depending on the application.

4. Go/No-Go Feature Taper ring gauges are often designed with two sections—the “Go” and the “No-Go.” The “Go” section must enter the part being measured, indicating that the part is within tolerance. In contrast, the “No-Go” section should not fit, confirming that the dimensions are correct.

How Taper Ring Gauges are Used

Using a taper ring gauge is straightforward but requires a trained operator to ensure accurate results. The process generally follows these steps

1. Preparation The component to be measured should be clean and free from debris to avoid false readings.

taper ring gauge

2. Insertion The operator places the gauge over or into the tapered hole or surface, starting with the Go section. If it fits smoothly, the dimensions are likely within tolerance.

3. Verification The operator then checks the No-Go section. If this section does not fit, it confirms that the taper meets specifications.

4. Record Keeping It is vital to document the measurements and outcomes for quality control records, which helps in maintaining manufacturing standards and procedures.

The Importance of Taper Ring Gauges in Industry

Taper ring gauges are invaluable in maintaining the quality and integrity of manufactured products. Here are a few reasons why they are essential

1. Precision They provide precise measurements, which are critical in ensuring that parts fit together correctly, especially in complex assemblies like engines or machinery.

2. Quality Control Regular use of taper ring gauges in production lines helps catch errors early, reducing the chances of defective products reaching the market.

3. Standardization They help adhere to industry standards and specifications, which is crucial for safety and performance, particularly in industries where tolerances are tight.

4. Cost-Effectiveness By preventing manufacturing defects and ensuring parts fit together correctly, taper ring gauges ultimately save companies money by reducing waste and rework.

Conclusion

In summary, taper ring gauges are essential tools in the realm of precision measurement, playing a crucial role in the quality control process across various industries. Their design, functionality, and importance in ensuring that components meet specified tolerances cannot be overstated. As industries continue to evolve and demand for precision grows, taper ring gauges will remain a fundamental part of the manufacturing toolkit, safeguarding the integrity and reliability of products across the board.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS