Dec . 11, 2024 10:03 Back to list

Understanding the Use and Applications of Taper Plug Gauges in Precision Measurement

Understanding Taper Plug Gauges A Comprehensive Overview

Taper plug gauges are essential tools in the field of manufacturing and quality control, used to verify the accuracy and precision of threaded holes and internal tapered surfaces in components. Their design is key to ensuring that products meet stringent specifications and operational requirements. This article delves into the characteristics, applications, and significance of taper plug gauges in various industries.

What Are Taper Plug Gauges?

Taper plug gauges are precision instruments used to measure the size and form of tapered holes. Unlike standard cylindrical plug gauges, taper plug gauges have a tapered profile, which allows them to fit correctly into conical or tapered openings. This design feature is crucial for ensuring that the gauge can accurately assess the geometric dimensions of the hole.

Typically, taper plug gauges are manufactured to specific standards, including ISO and ASME, which dictate their precision and allowable tolerances. Their construction generally consists of high-grade tool steel, which provides durability and resistance to wear, ensuring long-term use and reliability.

Design Features

The key design features of taper plug gauges include

1. Taper Angle The angle of the taper is a critical aspect of the gauge that must match the specifications of the workpiece being inspected. Common taper angles include 18, 112, and 116, with the selection depending on the application.

2. Length and Diameter The overall length and the diameter of the plug must be appropriate for the specific hole being measured. These dimensions are selected based on the depth and size of the tapered hole in the component.

3. Calibration Marks Many taper plug gauges come equipped with calibration marks. These markings help users quickly identify whether the gauge is within acceptable limits.

4. Finish The surface finish of taper plug gauges is refined to minimize friction and wear, ensuring that the gauges maintain their accuracy over time.

Applications of Taper Plug Gauges

Taper plug gauges are used extensively across various industries, including

taper plug gauge

- Aerospace In the aerospace sector, precision is paramount. Taper plug gauges are employed to ensure that threaded holes and tapered surfaces in aircraft components meet rigorous safety and performance standards.

- Automotive Automotive manufacturers use taper plug gauges for checking the fit of components such as engine blocks and transmission cases. Ensuring the proper taper helps maintain engine performance and reliability.

- Manufacturing In general manufacturing, these gauges help verify the dimensions of machined parts. This is essential for mass production where consistency and quality control are critical.

- Construction Taper plug gauges can also find applications in the construction industry, particularly in the fitting of tapered piping systems and welding components.

Importance of Taper Plug Gauges

The importance of taper plug gauges cannot be overstated. They are critical for several reasons

1. Quality Assurance By ensuring that components conform to their design specifications, taper plug gauges play a significant role in quality assurance processes.

2. Cost Efficiency Using taper plug gauges to identify out-of-spec components early in the manufacturing process helps reduce waste and lowers production costs.

3. Safety In industries such as aerospace and automotive, the safety of end-users hinges on the precision of components. Taper plug gauges contribute to the creation of reliable and safe products.

4. Compliance Many industries are governed by strict regulations requiring compliance with international standards. Taper plug gauges help manufacturers demonstrate adherence to these standards.

Conclusion

In summary, taper plug gauges are invaluable tools in the realm of precision measurement. Their ability to verify the dimensions of tapered holes ensures that components will function as intended in a variety of applications. With the ever-increasing demand for quality and efficiency in manufacturing, understanding and utilizing taper plug gauges is more important than ever. By ensuring accurate measurements, manufacturers can enhance the reliability of their products, promote safety, and maintain compliance with industry standards. Whether in aerospace, automotive, or general manufacturing, taper plug gauges continue to be essential for quality control and assurance.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

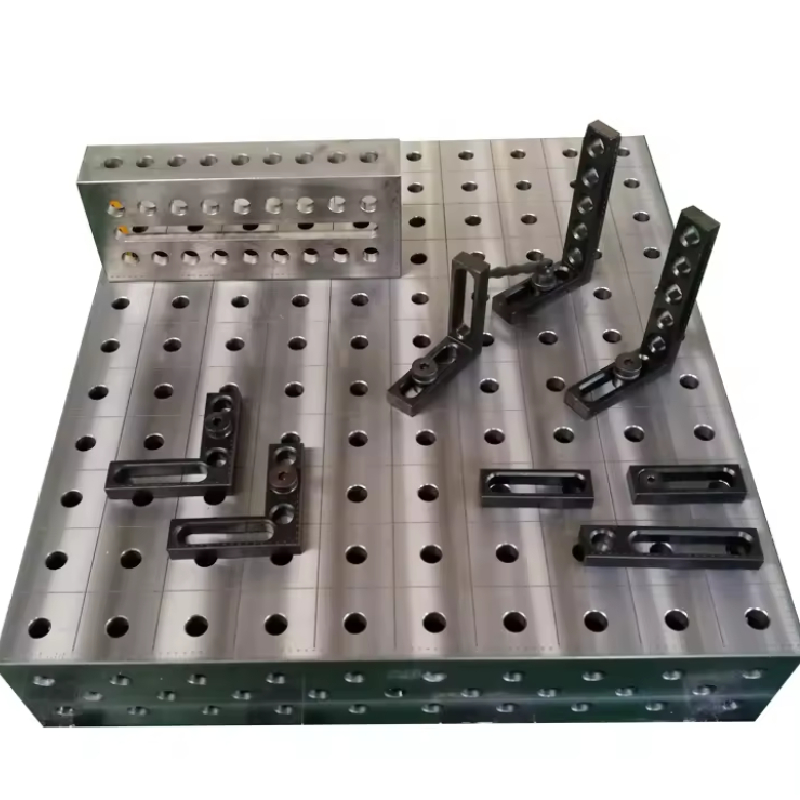

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS