Oct . 07, 2024 05:28 Back to list

standard pin gauge set

Understanding Standard Pin Gauge Sets A Comprehensive Overview

Pin gauges are essential tools widely used in engineering and manufacturing for measuring the diameter of holes and ensuring the accuracy of parts. Among the various types of measuring instruments, standard pin gauge sets stand out for their precision, versatility, and ease of use. This article delves into what standard pin gauge sets are, their composition, applications, and the importance of precision in modern manufacturing processes.

What is a Pin Gauge?

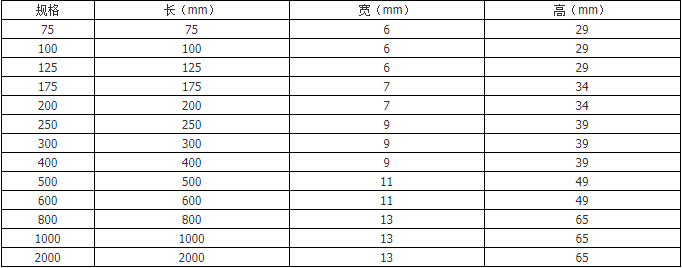

A pin gauge is a cylindrical tool that meets specific size standards, allowing users to measure the diameter of holes and openings in a variety of materials. These gauges come in various diameters, typically ranging from fractions of a millimeter to several centimeters. The primary characteristic of pin gauges is their high precision and consistency, which makes them invaluable in quality control and inspection tasks.

Composition of Standard Pin Gauge Sets

A standard pin gauge set typically consists of a series of pins, each of which is manufactured to a specific diameter. These sets may include both go and no-go gauges. The go pins are designed to fit into a hole, while the no-go pins are meant to be slightly larger than the specified hole dimension, thereby not fitting in. This dual-grouping system allows for thorough testing of dimensions to ensure that parts meet strict tolerances.

The pins in a standard gauge set are usually made from high-quality steel to resist wear and maintain their precision over time. They are often ground to extremely precise dimensions, ensuring that their size is reliable and consistent. Many pin gauges are also coated or treated to prevent corrosion and enhance durability.

Applications of Standard Pin Gauge Sets

Standard pin gauge sets are used across various industries, including aerospace, automotive, manufacturing, and quality assurance. They play a crucial role in tasks such as

standard pin gauge set

1. Quality Control Pin gauges are utilized to verify that parts meet specified tolerances and dimensions. By testing various features of components with pin gauges, manufacturers can ensure quality and functionality before mass production.

2. Setup and Calibration In production environments, pin gauges can be used to set up machines and tools accurately. They help in calibrating other measuring instruments and ensuring that they yield correct measurements.

3. Prototype Development Design engineers often use pin gauges during the prototype phase to ensure parts will fit together correctly. This practice is vital for reducing errors and ensuring efficient assembly.

4. Tooling and Dies Pin gauges are used to inspect the dimensions of tooling and dies, which must adhere to precise specifications for effective operation.

Importance of Precision

In today's manufacturing landscape, precision is paramount. As industries strive for higher efficiency and lower production costs, the significance of accurate measurement tools like pin gauge sets cannot be overstated. A minor discrepancy in dimensions can lead to significant issues, including component failure, increased waste, and higher rework costs.

Moreover, with the advent of advanced manufacturing technologies and automation, consistent accuracy is essential. Automated systems rely on precise measurements to function correctly, and the feedback provided by pin gauges plays a critical role in maintaining the integrity of these systems.

Conclusion

Standard pin gauge sets are indispensable tools in modern manufacturing and engineering. Their ability to provide precise measurements ensures that components fit and function as intended, safeguarding the quality and reliability of products across various industries. As technology advances and the demand for precision manufacturing continues to rise, the role of pin gauges will remain pivotal in achieving excellence in quality control and production processes. Understanding and utilizing these tools effectively is crucial for professionals aiming to uphold high standards in manufacturing.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS