Nov . 21, 2024 17:04 Back to list

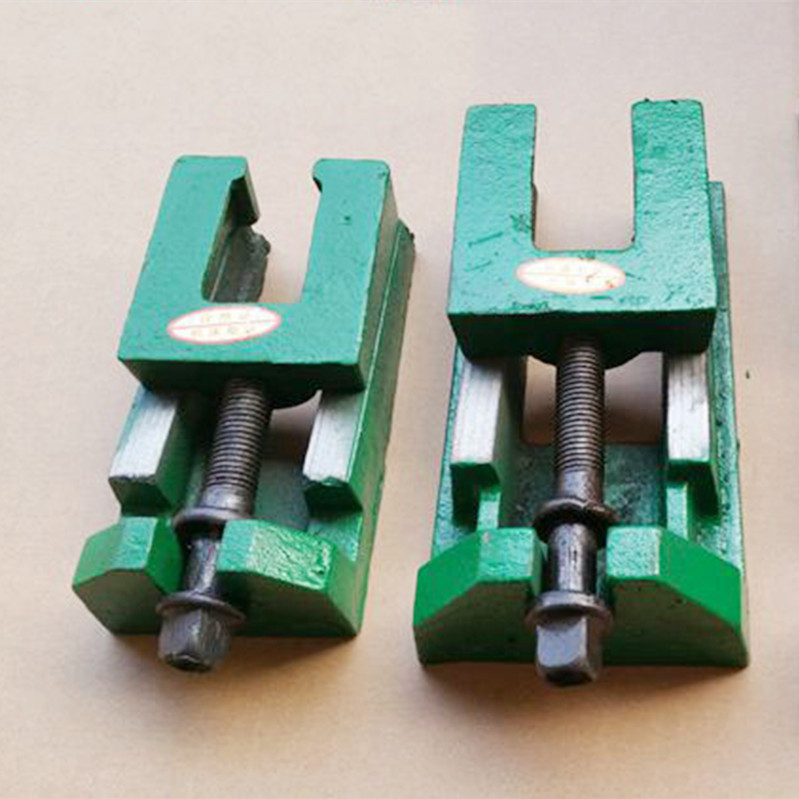

standard pin gauge set

Understanding the Standard Pin Gauge Set A Vital Tool for Precision Measurement

In industries where precision and accuracy are paramount, standard pin gauge sets play a crucial role in ensuring that products meet stringent specifications. These tools are essential for quality control and assurance in manufacturing processes across various sectors, including automotive, aerospace, and electronics. In this article, we will explore what pin gauge sets are, their importance, and how they are used in practice.

What is a Pin Gauge Set?

A pin gauge set is a collection of precision measuring tools, each consisting of a cylindrical pin made from high-quality material. These pins are manufactured to exact diameters and tolerances, making them ideal for verifying the dimensions of holes, slots, and other features in machined parts. Typically, a pin gauge set includes multiple pins that range in size from a few millimeters to several centimeters, allowing users to check a wide variety of dimensions.

Importance of Precision Measurement

Precision measurement is critical in many industries, where even the slightest deviation can lead to catastrophic failures or costly rework. For example, in the automotive industry, the fit and function of engine components must be perfect to ensure safety and performance. Pin gauges are effective tools for ensuring that the dimensions of these components are within specified tolerances.

Types of Pin Gauges

There are two primary types of pin gauges hole gauges and plug gauges.

1. Hole Gauges These pin gauges are used to measure the diameter of a hole. The gauge is inserted into the hole, and the correct size is determined by how easily or snugly the pin fits. If the pin gauge fits perfectly without force, it indicates that the hole is within specification.

2. Plug Gauges These are similar to hole gauges but are designed to check the dimensional accuracy of external features. Plug gauges are often used to confirm whether an external diameter meets the required specifications.

Using Pin Gauges

standard pin gauge set

Using a pin gauge set requires a systematic approach to ensure accuracy. First, it is essential to clean both the pin gauge and the part to be measured to remove any debris or contaminants that could affect the measurement. Next, the appropriate pin gauge should be selected based on the required size.

When using a pin gauge, the user inserts the pin into the feature being measured

. The fit should be assessed — whether it is too tight, too loose, or just right.- If a pin fits snugly, this indicates that the size is within tolerance. - If it is too loose, the hole is oversize. - If it is too tight, the hole is undersize.

This simple method provides a quick way to assess whether parts conform to the necessary specifications.

Advantages of Pin Gauge Sets

1. High Accuracy Pin gauges are manufactured to very tight tolerances, ensuring that they provide highly accurate measurements.

2. Durability Made from high-quality materials, pin gauges are built to withstand frequent use, maintaining their precision over time.

3. Ease of Use The straightforward design allows operators to use them with minimal training, making them an accessible tool for quality control.

4. Cost-Effective Investing in a set of pin gauges can save companies significant amounts of money by reducing waste and avoiding costly production errors.

Conclusion

In conclusion, standard pin gauge sets are indispensable tools for ensuring precision in manufacturing processes. Their ability to accurately measure dimensions makes them essential in various industries where quality control is vital. By understanding the applications and uses of pin gauges, companies can enhance their production processes, reduce waste, and ultimately deliver better products to their customers. As technology continues to advance, the evolution of measuring tools will likely bring even more innovations, but the fundamental reliability of pin gauges will always remain a cornerstone of precision engineering.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS