Sep . 25, 2024 18:53 Back to list

snap on dial gauge

Understanding the Snap-On Dial Gauge A Precision Tool for Every Mechanic

In the world of mechanics and engineering, precision is paramount. Tools that provide accurate measurements are essential for ensuring the reliability and performance of various components. One such invaluable tool is the Snap-On dial gauge, a benchmark in the realm of measuring devices. This article explores the features, benefits, and applications of the Snap-On dial gauge, shedding light on why it is a favorite among professionals and hobbyists alike.

What is a Snap-On Dial Gauge?

A dial gauge, also known as a dial indicator, is an instrument used to measure small distances with high accuracy. The Snap-On dial gauge, a product by the renowned Snap-On Tools Company, is particularly lauded for its robustness and precision. Typically equipped with a needle that moves over a calibrated dial, it provides readings to 0.001 inches or finer, making it suitable for various applications in mechanics, machining, and quality control.

Key Features

1. High Precision One of the most significant advantages of the Snap-On dial gauge is its exceptional accuracy. With a resolution of 0.001 inches, it ensures precise measurements, which are crucial for tasks like aligning parts or checking the flatness of surfaces.

2. Durability Constructed from high-quality materials, Snap-On tools are built to last. The rugged design of the dial gauge ensures that it can withstand the rigors of a busy workshop and resist wear over time.

3. Easy to Read The dial face is designed for clear visibility, often featuring contrasting colors that make it easy to read measurements from any angle. This user-friendly design reduces the likelihood of errors during measurement.

4. Versatility Snap-On dial gauges come with various accessories that enhance their functionality. Depending on the model, they may include different probes, mounts, or extension bars, making them adaptable for a wide range of applications.

5. Calibration For any precision instrument, calibration is essential. Snap-On dial gauges are typically easy to calibrate, allowing users to maintain accuracy over time, ensuring consistent performance.

snap on dial gauge

Applications

The Snap-On dial gauge is used in various applications across multiple industries

1. Automotive Mechanics In automotive repair, dial gauges are vital for measuring the runout of wheels, the wear on brake rotors, and the alignment of components. Their ability to detect minute deviations helps mechanics diagnose and resolve issues efficiently.

2. Machining In manufacturing settings, particularly in precision machining, dial gauges are used to measure the depth of holes, the flatness of surfaces, and the concentricity of shafts. This ensures that components meet stringent tolerances necessary for high-performance machinery.

3. Quality Control In quality assurance processes, measuring with a dial gauge helps in the inspection of manufactured parts. It ensures that components are produced to specification, aiding in maintaining high standards of quality.

4. Research and Development Engineers and scientists rely on dial gauges for experimental measurements in research labs. The precision and reliability of these instruments are crucial in developing new materials and technologies.

Conclusion

The Snap-On dial gauge exemplifies the combination of precision, durability, and versatility. For anyone involved in mechanics, machining, or quality control, having a reliable measuring tool is essential. The Snap-On dial gauge not only meets these needs but exceeds expectations, empowering users to achieve a high level of accuracy in their work.

By investing in a Snap-On dial gauge, mechanics and engineers are equipped with a tool that enhances their capabilities, reduces errors, and ultimately contributes to the successful execution of various projects. Whether you are a professional mechanic, a machinist, or an enthusiast, a Snap-On dial gauge is a worthy addition to your toolkit, helping you achieve precision in every task.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

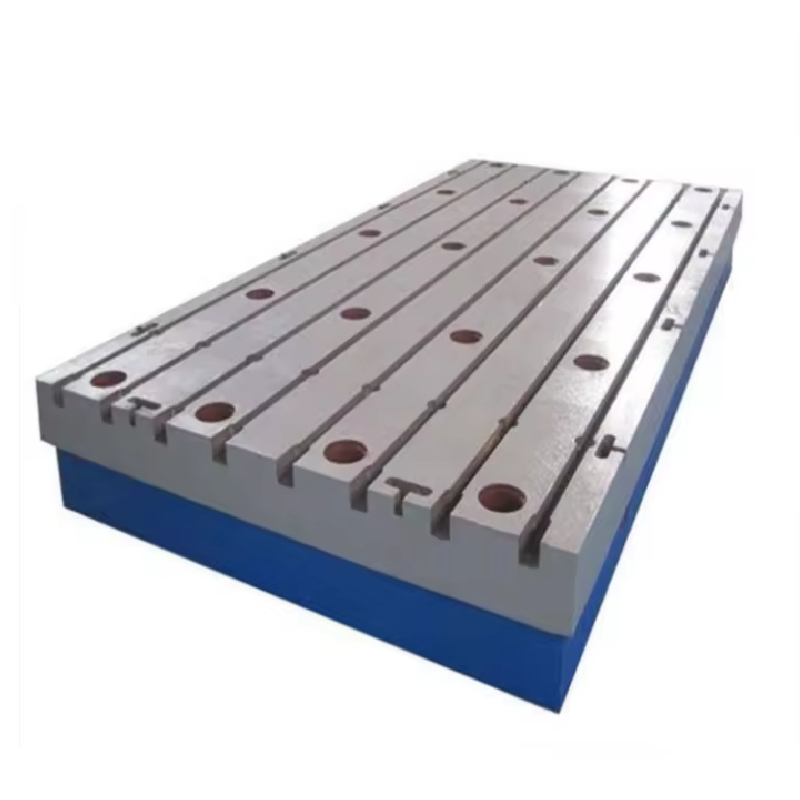

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS