Dec . 10, 2024 06:40 Back to list

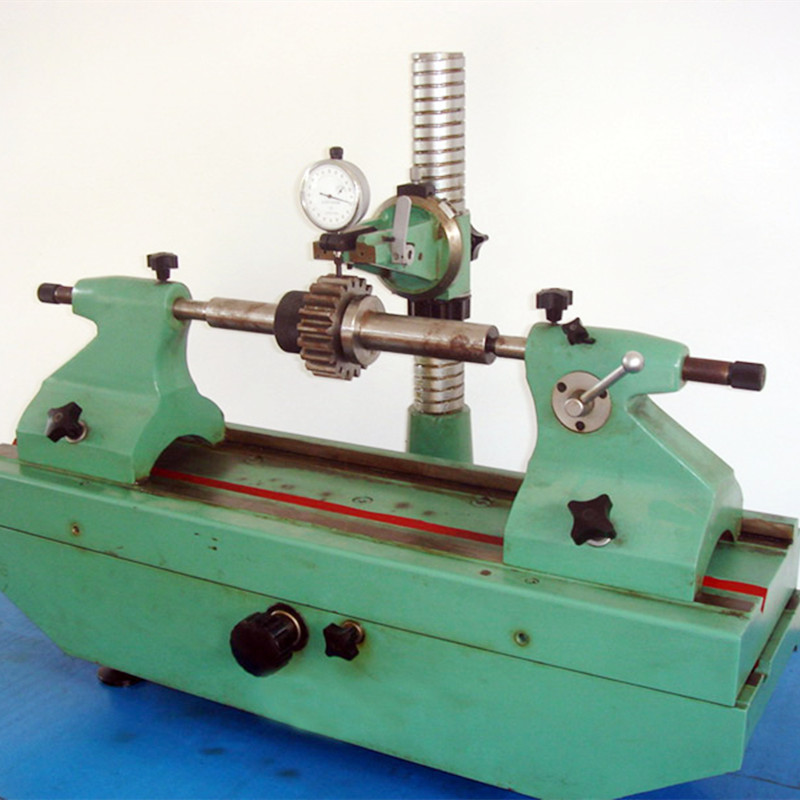

screw thread plug gauge

Understanding Screw Thread Plug Gauges Importance and Applications

Screw thread plug gauges are pivotal instruments in the field of manufacturing and engineering, particularly when it comes to ensuring the accuracy and reliability of threaded components. These gauges are specialized tools designed to check the acceptability of internal threads in various mechanical parts. Their application spans across several industries including automotive, aerospace, and general manufacturing.

What is a Screw Thread Plug Gauge?

A screw thread plug gauge is a measuring instrument that is used to determine the functional characteristics of screw threads. This gauge is usually cylindrical in shape and is equipped with a threaded end that matches the specifications of the thread being measured. Plug gauges come in two varieties the go gauge and the no-go gauge. The go gauge is designed to fit into the threaded hole if the internal threads are within the specified tolerances, whereas the no-go gauge should not fit if the threads are within specification. This two-gauge system allows for a straightforward pass/fail type of assessment.

Importance in Quality Control

The precision of threaded components is critical for the overall functionality and safety of machinery. Any deviations in thread dimensions can lead to improper fits, which can result in mechanical failures or even catastrophic accidents. Therefore, screw thread plug gauges play a crucial role in quality control processes. Manufacturers often utilize these gauges at various stages of production to ensure that every threaded part meets the necessary specifications before it continues down the production line.

Standards and Specifications

screw thread plug gauge

Screw thread plug gauges conform to various international standards such as ANSI (American National Standards Institute), ISO (International Organization for Standardization), and ASME (American Society of Mechanical Engineers). These standards dictate the allowed tolerances for different types of threads, such as UNC (Unified National Coarse), UNF (Unified National Fine), and metric threads. Utilizing the correct gauge for the corresponding standard is vital for ensuring compatibility and performance in assembled products.

Applications Across Industries

In the automotive industry, screw threads are ubiquitous in the assembly of engines, transmissions, and various components. A small flaw in a threaded connection can result in significant issues such as oil leaks or mechanical failure. In aerospace, where safety and reliability are paramount, the importance of accurate screw thread measurement cannot be overstated. In manufacturing sectors, screw thread plug gauges are used to ensure consistency across large batches of threaded products, contributing to overall manufacturing efficiency and reducing costly errors.

Maintenance and Calibration

To ensure their effectiveness, screw thread plug gauges must be regularly maintained and calibrated. Any wear or damage to the threads can affect the accuracy of the measurements. Periodic checks against certified standards help maintain their reliability. Keeping these gauges in good condition is essential for adhering to quality assurance protocols and ensuring that manufactured parts meet the necessary specifications.

Conclusion

Screw thread plug gauges are indispensable tools in the manufacturing realm, serving as an essential means of verifying the integrity of threaded components. Their application not only boosts the quality of individual parts but also enhances the overall safety and performance of machinery and equipment. As industries continue to pursue higher standards of precision and reliability, the role of screw thread plug gauges will only become more prominent, solidifying their position as a critical element in quality control methodologies. By ensuring the accuracy of threaded components, manufacturers can mitigate risks, improve product performance, and enhance customer satisfaction, reaffirming the significant value of these simple yet vital tools in modern engineering and manufacturing practices.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS