Jun . 27, 2024 01:51 Back to list

Sanitary Butterfly Valve Premium Quality for Hygienic Applications

The Significance of the 6 Sanitary Butterfly Valve in Modern Industry

In the realm of industrial processing and fluid control systems, the 6 sanitary butterfly valve holds a pivotal position due to its exceptional performance and versatility. This specialized valve is specifically designed for applications where maintaining high levels of cleanliness and hygiene is paramount, such as in the food and beverage, pharmaceutical, and chemical industries.

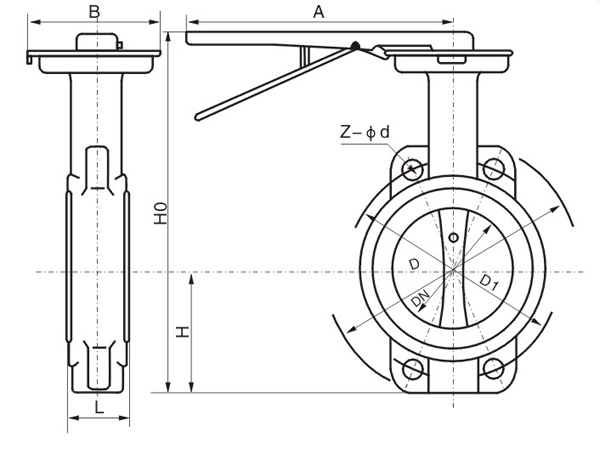

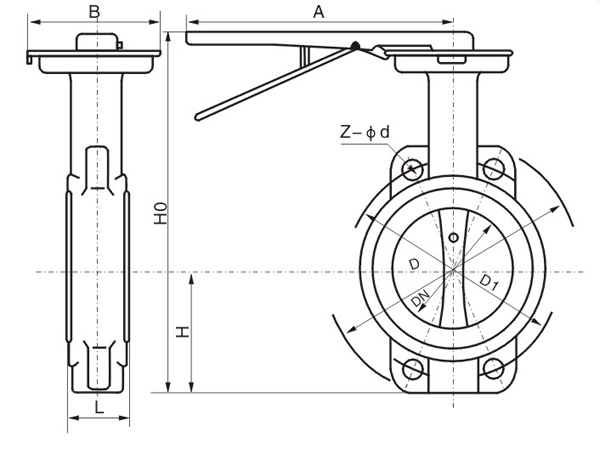

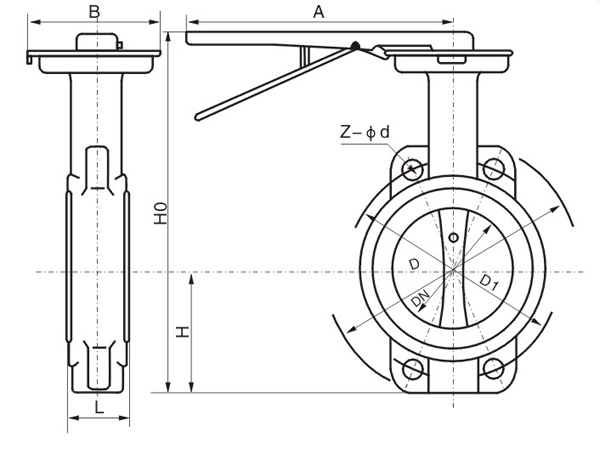

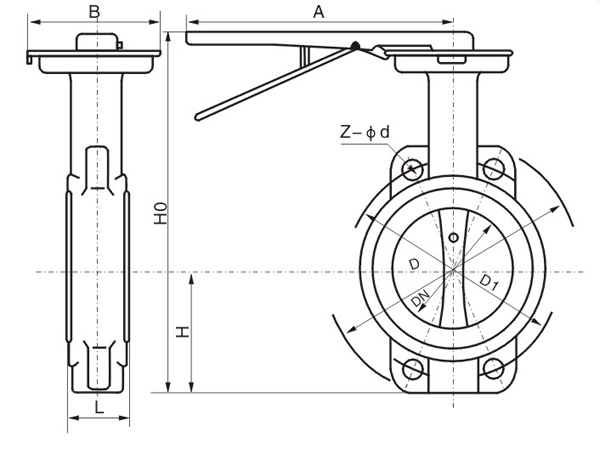

A butterfly valve, in general, operates by using a disc or butterfly that rotates on a central shaft to regulate flow. The 6-inch variant refers to the nominal pipe size, indicating its capacity to handle larger volumes of fluid. Sanitary butterfly valves, on the other hand, are constructed with materials and finishes that meet strict, ensuring minimal contamination and ease of cleaning.

The 6 sanitary butterfly valve combines efficiency and durability with its streamlined design. Its lightweight structure allows for quick and easy installation, while its compact size enables it to fit into tight spaces. The valve's large port diameter promotes unhindered flow, reducing pressure loss and enhancing overall system efficiency.

One of the key features of the 6 sanitary butterfly valve is its tri-clamp connection. This design facilitates rapid assembly and disassembly without the need for special tools, making maintenance and cleaning processes more convenient. The valve's sealing mechanism, usually a resilient seat or metal-to-metal seal, ensures a tight shut-off, preventing leaks and maintaining the purity of the processed material.

Furthermore, the sanitary butterfly valve offers a wide range of control options

Furthermore, the sanitary butterfly valve offers a wide range of control options Furthermore, the sanitary butterfly valve offers a wide range of control options

Furthermore, the sanitary butterfly valve offers a wide range of control options

Furthermore, the sanitary butterfly valve offers a wide range of control options

Furthermore, the sanitary butterfly valve offers a wide range of control options 6 sanitary butterfly valve. From manual operation to pneumatic or electric actuators, these valves can be easily automated to suit various process requirements. Their quick opening and closing action also makes them suitable for applications requiring frequent cycling.

In the context of food and beverage industry, the 6 sanitary butterfly valve is instrumental in ensuring product safety and quality. It prevents particle buildup, minimizing the risk of contamination, and its smooth surface finish makes it resistant to corrosion and easy to sanitize.

In the pharmaceutical sector, where sterility is crucial, the valve's ability to withstand harsh cleaning chemicals and high-temperature sterilization cycles makes it an indispensable component. In chemical plants, the valve's robustness and resistance to corrosive fluids make it a reliable choice.

In conclusion, the 6 sanitary butterfly valve is not just a tool but a testament to the harmonious blend of functionality and hygiene in modern industrial operations. Its design, performance, and adaptability make it a go-to solution for industries where cleanliness and process efficiency are non-negotiable. As technology continues to evolve, we can expect even more advanced iterations of this valve to emerge, further enhancing the standards of safety and productivity in various sectors.

6 sanitary butterfly valve. From manual operation to pneumatic or electric actuators, these valves can be easily automated to suit various process requirements. Their quick opening and closing action also makes them suitable for applications requiring frequent cycling.

In the context of food and beverage industry, the 6 sanitary butterfly valve is instrumental in ensuring product safety and quality. It prevents particle buildup, minimizing the risk of contamination, and its smooth surface finish makes it resistant to corrosion and easy to sanitize.

In the pharmaceutical sector, where sterility is crucial, the valve's ability to withstand harsh cleaning chemicals and high-temperature sterilization cycles makes it an indispensable component. In chemical plants, the valve's robustness and resistance to corrosive fluids make it a reliable choice.

In conclusion, the 6 sanitary butterfly valve is not just a tool but a testament to the harmonious blend of functionality and hygiene in modern industrial operations. Its design, performance, and adaptability make it a go-to solution for industries where cleanliness and process efficiency are non-negotiable. As technology continues to evolve, we can expect even more advanced iterations of this valve to emerge, further enhancing the standards of safety and productivity in various sectors.

Furthermore, the sanitary butterfly valve offers a wide range of control options

Furthermore, the sanitary butterfly valve offers a wide range of control options

Furthermore, the sanitary butterfly valve offers a wide range of control options

Furthermore, the sanitary butterfly valve offers a wide range of control options 6 sanitary butterfly valve. From manual operation to pneumatic or electric actuators, these valves can be easily automated to suit various process requirements. Their quick opening and closing action also makes them suitable for applications requiring frequent cycling.

In the context of food and beverage industry, the 6 sanitary butterfly valve is instrumental in ensuring product safety and quality. It prevents particle buildup, minimizing the risk of contamination, and its smooth surface finish makes it resistant to corrosion and easy to sanitize.

In the pharmaceutical sector, where sterility is crucial, the valve's ability to withstand harsh cleaning chemicals and high-temperature sterilization cycles makes it an indispensable component. In chemical plants, the valve's robustness and resistance to corrosive fluids make it a reliable choice.

In conclusion, the 6 sanitary butterfly valve is not just a tool but a testament to the harmonious blend of functionality and hygiene in modern industrial operations. Its design, performance, and adaptability make it a go-to solution for industries where cleanliness and process efficiency are non-negotiable. As technology continues to evolve, we can expect even more advanced iterations of this valve to emerge, further enhancing the standards of safety and productivity in various sectors.

6 sanitary butterfly valve. From manual operation to pneumatic or electric actuators, these valves can be easily automated to suit various process requirements. Their quick opening and closing action also makes them suitable for applications requiring frequent cycling.

In the context of food and beverage industry, the 6 sanitary butterfly valve is instrumental in ensuring product safety and quality. It prevents particle buildup, minimizing the risk of contamination, and its smooth surface finish makes it resistant to corrosion and easy to sanitize.

In the pharmaceutical sector, where sterility is crucial, the valve's ability to withstand harsh cleaning chemicals and high-temperature sterilization cycles makes it an indispensable component. In chemical plants, the valve's robustness and resistance to corrosive fluids make it a reliable choice.

In conclusion, the 6 sanitary butterfly valve is not just a tool but a testament to the harmonious blend of functionality and hygiene in modern industrial operations. Its design, performance, and adaptability make it a go-to solution for industries where cleanliness and process efficiency are non-negotiable. As technology continues to evolve, we can expect even more advanced iterations of this valve to emerge, further enhancing the standards of safety and productivity in various sectors.

Latest news

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS