Nov . 29, 2024 23:50 Back to list

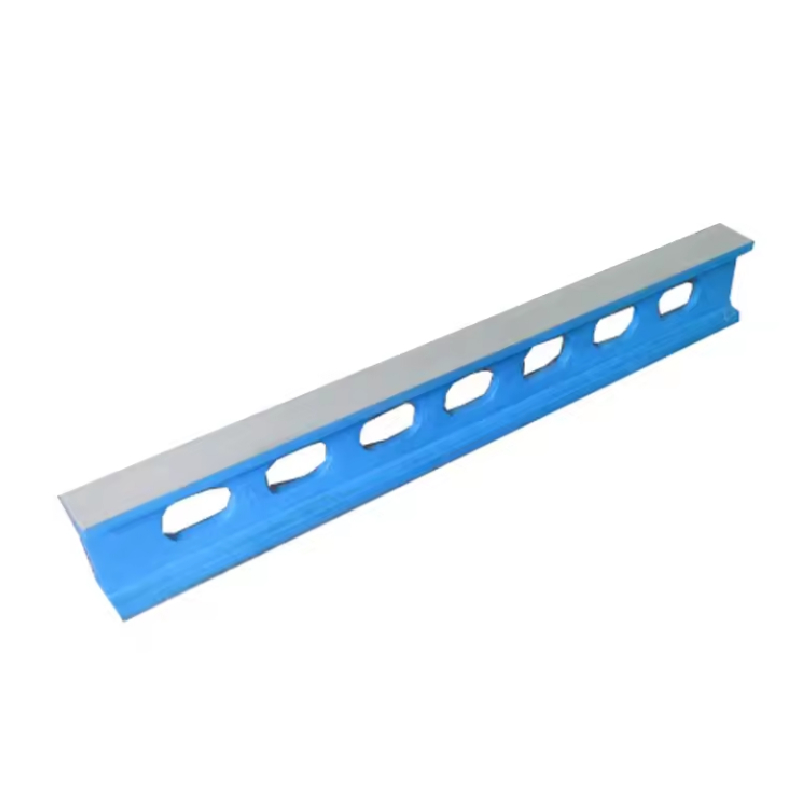

ring gauge set

Understanding the Importance of Ring Gauge Sets in Precision Measurement

In the world of manufacturing and precision engineering, the ability to measure internal diameters accurately is crucial. One of the key tools used for this purpose is the ring gauge set. Ring gauges are essential instruments designed to determine the size and tolerance of parts, ensuring that they meet specified dimensions during the manufacturing process. This article aims to explore the significance of ring gauge sets, their types, features, and applications in various industries.

What is a Ring Gauge Set?

A ring gauge set is a collection of precision instruments, typically made from high-grade steel, designed to check the internal dimensions of cylindrical parts. These gauges come in a variety of sizes and tolerances, allowing engineers and machinists to verify the accuracy of their work. The set usually consists of both go and no-go gauges the go gauge checks if a part is within the minimum acceptable size, while the no-go gauge ensures that it does not exceed the maximum acceptable dimensions.

Types of Ring Gauges

There are several types of ring gauges, each catering to different measurement needs

1. Fixed Ring Gauges These gauges have a permanent size and are used for standard measurements. They are particularly useful for checking the internal diameters of holes and cylinders.

2. Adjustable Ring Gauges These gauges allow for size adjustments and are advantageous when working with varying dimensions, making them versatile for different projects.

3. Plug Gauges Though not strictly ring gauges, they are used alongside ring gauges for thorough inspections. Plug gauges measure the depth and internal dimensions alongside the ring gauges.

Features of Quality Ring Gauge Sets

ring gauge set

When selecting a ring gauge set, it's important to consider certain features that indicate quality and reliability. These include

- Material High-quality gauges are made from tool steel or other durable materials that resist wear and deformation over time. - Calibration Regular calibration ensures that the gauges maintain their accuracy. Quality sets either come pre-calibrated or include information on calibration protocols. - Finish A smooth, non-reflective finish helps to prevent measurement errors by reducing light reflection, which can interfere with readings. - Storage and Carrying Cases A proper storage solution protects gauges from damage and ensures that they remain organized and easy to transport.

Applications of Ring Gauge Sets

Ring gauge sets find applications in various industries, notably

1. Manufacturing In manufacturing, particularly in the automotive and aerospace sectors, ring gauges are used to check the tolerances of component parts, ensuring they fit together correctly.

2. Tooling In toolmaking, they serve to validate the dimensions of cutting tools, which significantly impacts the precision of machining operations.

3. Quality Control Ring gauges are critical in quality assurance processes, where they help maintain high standards and compliance with industry regulations.

4. R&D In research and development, engineers employ ring gauge sets to develop prototypes, ensuring that all components meet the design specifications.

Conclusion

Ring gauge sets are indispensable tools in precision measurement, playing a vital role in ensuring quality and accuracy across manufacturing and engineering disciplines. With a variety of types and features, these gauges provide the reliability needed for internal dimension checks. As industries continue to advance and demand higher precision, the importance of ring gauge sets will only grow, solidifying their place as essential components of effective quality control and manufacturing processes. Investing in a high-quality ring gauge set is indeed crucial for any organization aiming for excellence in production and engineering practices.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS