Aug . 14, 2024 02:11 Back to list

Reliable 2 Inch Check Valve for Efficient Flow Control and System Protection Solutions

Understanding the 2-Inch Check Valve Importance, Functionality, and Applications

The 2-inch check valve is a critical component in many fluid systems, serving as a simple yet effective solution to prevent backflow. This essential mechanical device is designed to allow fluid to flow in one direction only, ensuring that systems operate efficiently and safely.

What is a Check Valve?

At its core, a check valve is a type of flow control device that opens with the forward flow of fluid and closes when there is a reverse flow. The mechanics behind this operation rely on the valve's internal components, which typically include a disc or ball that moves within the valve body. When fluid pressure is applied from one side, the valve opens, allowing the fluid to pass through. Conversely, if the pressure decreases or reverses, the valve closes, effectively preventing backflow.

Why Choose a 2-Inch Check Valve?

The size of the valve, in this case, 2 inches, denotes the diameter of the pipe it connects to. This size is suitable for various applications, particularly in residential and light industrial contexts. It strikes a good balance between flow capacity and space efficiency, making it a popular choice for plumbing, sewage systems, and irrigation setups.

Key Features and Benefits

1. Preventing Backflow The most significant advantage of a check valve is its ability to prevent backflow, which can cause contamination, equipment damage, and system inefficiencies. In applications where fluids need to remain uncontaminated—such as potable water systems—the 2-inch check valve becomes indispensable.

2. Maintenance-Free Operation Typically, check valves require minimal maintenance, as they are designed to be self-activating. This simplicity reduces operational costs and minimizes downtime, allowing systems to run smoothly without frequent checks.

3. Versatile Applications The 2-inch check valve can be used in various scenarios. From irrigation systems that require water to flow in one direction to HVAC systems and industrial processes that need to pump fluids efficiently, this valve's adaptability makes it a valuable asset across industries.

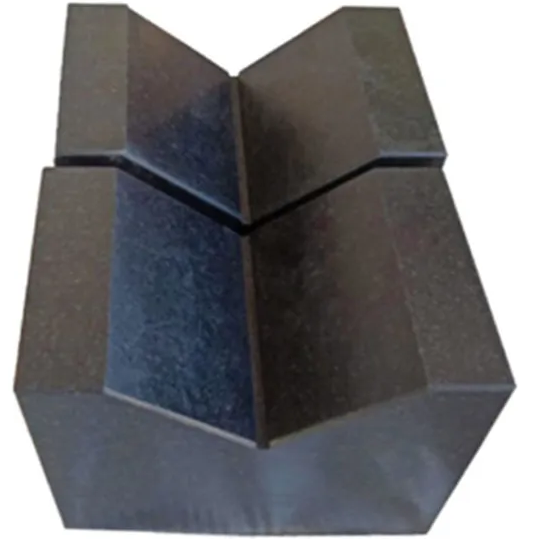

2 inch check valve

4. Durability Many 2-inch check valves are made from durable materials such as brass, stainless steel, or PVC, which can withstand corrosive fluids and high temperatures. The choice of material will often depend on the specific application and the fluid being handled.

5. Easy Installation The installation of a 2-inch check valve is generally straightforward. It can be fitted inline in existing piping systems, and with their common size, they are compatible with various fittings and fixtures.

Applications in Different Industries

1. Water Supply Systems In municipal water supply and sewage systems, 2-inch check valves help maintain pressure and prevent back-siphonage, ensuring clean water delivery to homes and businesses.

2. Agriculture In irrigation systems, these valves are essential for ensuring that water only flows to areas that need it, helping to conserve water and maximize agricultural efficiency.

3. Industrial Processes Many industrial operations utilize check valves to regulate the flow of liquids in manufacturing processes, often dealing with hazardous materials where preventing backflow is critical for safety.

4. HVAC Systems In heating and cooling systems, check valves ensure that refrigerants and water circulate correctly to optimize system performance.

Conclusion

The 2-inch check valve plays a vital role in numerous applications, vital for ensuring system efficiency and safety. By understanding its function and benefits, industries can make informed decisions to enhance their fluid management systems. Whether in residential plumbing, agricultural irrigation, or complex industrial processes, a reliable check valve is essential for robust and sustainable operation.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS