Jul . 29, 2025 19:20 Back to list

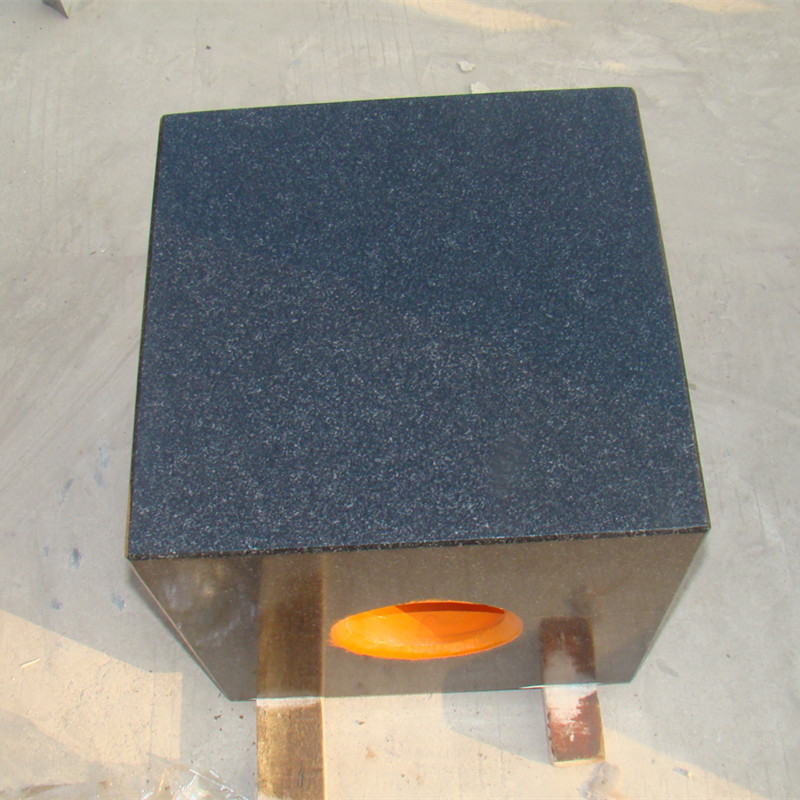

Premium Granite Box for Décor & Storage | Elegant Durable Design

1. Granite Box & Related Products: Industry Insights and Current Trends

The Granite Box is a precision-engineered product offering unrivaled durability, stability, and precision in industrial environments. Alongside alternatives such as block of granite, marble stone box, square marble box, and large marble box, these products are critical components in metrology, tooling, and industrial measurement sectors.

- Industry Trend (2024): Data from the International Federation of Robotics indicates that over 35% of high-precision machinery installs in 2023 specified granite-based metrology or assembly supports, signaling rising market adoption.

- Material Focus: Demand for granite box and marble stone box has grown steadily due to their intrinsic rigidity, low thermal expansion (Granite's coefficient: ~4.8x10-6/°C vs. steel: ~12.0x10-6/°C), and superior corrosion resistance.

| Year | Granite Box Demand (Units, thousands) | Marble Box Demand (Units, thousands) | Average Price (USD) | Application Growth Rate (%) |

|---|---|---|---|---|

| 2021 | 48 | 17 | $388 | 8.5% |

| 2022 | 56 | 21 | $399 | 11.2% |

| 2023 | 66 | 27 | $427 | 15.8% |

| 2024(E) | 78 | 33 | $440 | 17.5% |

Noteworthy: This surge aligns with increased ISO/ANSI calibration requirements and tightening QA protocols in aerospace, petrochemical, and metallurgical facilities.

2. Material, Engineering, and Performance Specifications Overview

| Parameter | Granite Box | Block of Granite | Marble Stone Box |

|---|---|---|---|

| Material | Black Granite (ISO 8512-2) | Natural Granite | Processed Marble |

| Compressive Strength | 220-250 MPa | 195-215 MPa | 120-155 MPa |

| Tensile Strength | 7.8-9.2 MPa | 6.5-8.0 MPa | 8.5-11.0 MPa |

| Flatness Tolerance | ≤ 8 μm/m | ≤ 18 μm/m | ≤ 20 μm/m |

| Surface Hardness | HS 70-90 | HS 65-83 | HS 57-74 |

| Thermal Expansion | 4.80×10-6/°C | 5.20×10-6/°C | 8.20×10-6/°C |

| Density | 3,070 kg/m³ | 2,950 kg/m³ | 2,680 kg/m³ |

| Corrosion Resistance | Excellent | Excellent | Good |

| Typical Sizes | 100×100×100 mm up to 1500×1000×400 mm | Custom | 120×120×180 mm up to 1200×600×400 mm |

3. Granite Box Manufacturing Process: Visualized Workflow

Manufacturing a granite box requires advanced material selection, precision engineering, and rigorous quality checks. The following diagram outlines a typical end-to-end production process:

→ Hand-selected, high-density black granite blocks (as per ISO 8512-2) are acquired for crack-free, homogeneous composition.

→ Diamond wire saws and multi-axis CNC machining shape the block close to the desired geometry.

→ CNC surface grinding achieves flatness & parallelism (

<8μm/m), while all holes/inserts are milled and threaded to ANSI B5.9 tolerance.

→ Semi-automated lapping reaches mirror-like surface, ensuring hardness & scratch-resistance for dimensional calibration.

→ Final product is cleansed, sealed with anti-corrosive coatings, and metal inserts are securely bonded or pinned.

→ Each granite box undergoes full dimension, hardness, and flatness validation against ISO 8512 / ANSI B89 standards.

→ Precision crating, serialization, and export-compliant documentation ensure traceability and safe transport.

Watch short process overview video: How Granite Metrology Blocks Are Crafted

- Key Manufacturing Technologies: Precision lapping, CNC 5-axis machining, diamond wire cutting, ultrasonic flaw detection

- Quality Certifications: Each granite box is supplied with an ISO 9001 and ISO 8512 calibration certificate.

4. Manufacturer Comparison: Granite Box vs. Block of Granite, Marble Stone Box

| Feature | Granite Box [STR Machinery] | Block of Granite [Generic] | Marble Stone Box [Domestic] |

|---|---|---|---|

| Material Source | Premium Africa/India Black Granite | Regional Quarries | Domestic Marble Block |

| Manufacturing Process | Full CNC + Lapping + ISO Test | Semi-manual Saw & Plane | Manual Cutting/Polishing |

| Flatness Precision | ≤ 8 μm/m | ≤ 20 μm/m | ≤ 22 μm/m |

| Size Capacity | From 100 mm up to 2000 mm | 100 mm - 1500 mm | 200 mm - 1200 mm |

| Corrosion Protection | Anti-Ox Layer + Epoxy | None/Simple Wax | Polish Only |

| ISO Certification | ISO 8512, ISO 9001 | No | No |

| Warranty | 3 Years / 5 Years (Optional) | None/1 Year | 1 Year |

| Custom Capability | Complex CNC Pockets, Inserts | None | Simple Holes |

| Major Industries Served | Petrochemical, Metallurgy, Waterworks, Aerospace | Construction, General | Decoration, Building |

| Sample Lead Time | 7 Days | 18 Days | 15 Days |

5. Custom Solutions: Design, Application, and Support

STR Machinery offers tailored granite box and square marble box solutions to fit demanding industrial, scientific, and calibration environments:

- Custom Size & Features: Up to 2,500 mm length, up to 500 mm thickness, custom slots/holes/pockets, various inserts (SS, brass) for fixture mounting.

- Application Engineering: Extensive collaboration with R&D labs, QA facilities, fluid processing, and OEMs worldwide.

- Lead Time: Standard granite box: 10-14 working days; Custom complex: 18-24 days (ex-factory, excl. shipping).

- Documentation: ISO-certified inspection report, CAD drawing, maintenance guide, and calibration certificate included.

- After-sales: 3-year comprehensive warranty, 1-year on-site recalibration (Europe, SE Asia, NA, ME), and lifetime technical counseling.

- Notable Clients: SGS, Shell, Thyssenkrupp, Enbridge Inc., Qatar Petrochemical.

6. Case Study: Granite Box in Precision Waterworks Measurement

- Specification: Flatness ≤8 μm, corrosion protection epoxy, six SS inserts for flexible instrumentation.

- Implementation: Delivered and installed within 16 days, certified to ISO 9001 process traceability, supported by on-site training for measurement crew.

- Performance Data: Reduced downtime by 29%, improved volumetric measurement repeatability from ±13 μm to ±6 μm (mean) — supporting audit and engineering records for metrology compliance.

- Client Feedback: “STR’s granite box solution notably enhanced both workflow and accuracy in our ISO/IEC 17025 lab validation.” — Chief Metrologist, EastAsia Water Inc.

FAQ: Professional Technical Questions & Answers

- 1. What is the standard material used for a Granite Box?

- The primary material is black granite of grade 00 or 0 (per ISO 8512-2), offering ultra-low thermal expansion and high compressive strength. Select marble stone boxes use dense Italian or Indian marble for cost-sensitive applications.

- 2. What are the typical size and flatness tolerances for a granite box?

-

Standard dimensions range from 100×100×100 mm to 2000×1200×400 mm. Flatness tolerance (per ISO 8512/ANSI B89):

≤8 μm/mfor high-precision applications. - 3. How does CNC machining improve precision in granite box production?

- CNC ensures consistent surface flatness, parallelism, and geometric accuracy. Automated tool paths minimize operator error and comply with stringent international standards.

- 4. Which certifications are supplied with each granite box?

- Every granite box is provided with ISO 9001 factory QA certificate, ISO 8512 (for flatness/size), and an individual calibration report traceable to NIST or local metrology bureaus.

- 5. What is the recommended maintenance cycle for a granite box?

- Clean the surface with lint-free cloth, avoid abrasive detergents, and recalibrate every 18–36 months depending on industrial load (per ASTM E2877).

- 6. What is the standard installation protocol?

- Place on vibration-isolated leveling bases, verify flatness using a certified electronic level/laser, and secure metal inserts as needed (see manufacturer's mounting instructions).

- 7. How long is the product warranty and what support is available?

- STR Machinery provides a 3-year full structural warranty and lifetime tech support, including on-site calibration for certified industrial/lab users.

7. Delivery, Warranty & Client Support

- Delivery Cycle: Stock items: 3–5 business days; Custom/CNC: 10–18 business days (ex-factory).

- Packaging: Shockproof wooden crates, dust/vapor barrier, real-time tracking with QR code traceability.

- Warranty: Full 3 years warranty, extendable to 5 years; covers material, flatness, and process defects.

- After-sales Service: On-site recalibration (Europe/NA/Asia), online diagnostics, application consulting by senior metrology engineers (ISO/FDA projects supported).

- Customer Support Hotline: service@strmachinery.com (24/7 dedicated response).

- Document Portal: Technical drawings, calibration certificates, and maintenance SOPs digitally provided for every shipped granite box.

8. References & Further Reading

- International Federation of Robotics. 2024 Market Study on Precision Granite Supports: https://ifr.org/downloads

- ASM International, “Granite and Marble Supports for Metrology: Comparative Material Review”, asminternational.org, 2023.

- ISO 8512-2:2020 — Measurement Standards of Granite Surface Plates, https://www.iso.org/standard/71309.html

- “Flatness Calibration and Maintenance of Granite Measuring Equipment”, Swiss Precision Forum, 2024.

- National Metrology Institute (NPL), UK “Use of Granite in Industrial QA”, npl.co.uk

— Swiss Precision Community Forum, 2024

This is the last article

-

Thread Plug Gauge Requires Careful HandlingNewsJul.29,2025

-

Surface plate calibrationNewsJul.29,2025

-

Ring Gauge Ensures Machining AccuracyNewsJul.29,2025

-

Pad Iron Reinforces Anchor PointsNewsJul.29,2025

-

Ground anchor stabilizes embankmentsNewsJul.29,2025

-

Granite Box Maintains Precision FlatnessNewsJul.29,2025

Related PRODUCTS