Aug . 08, 2025 01:00 Back to list

Precision Measurement Platform for Industrial Inspection

In the rapidly evolving landscape of industrial manufacturing and quality control, precision is not just a virtue—it's a fundamental requirement. From the microscopic components of advanced electronics to the colossal structures of aerospace engineering, accurate measurement underpins every aspect of design, production, and quality assurance. At the heart of this critical need lies the **measurement platform**, a sophisticated engineered solution designed to provide stable, accurate, and repeatable measurements in diverse and demanding environments. This comprehensive guide delves into the essence of the **measurement platform**, exploring its technological advancements, critical applications, and the profound impact it has on industrial efficiency and product reliability.

Industry Trends Driving the Demand for Advanced **Measurement Platform**s

The global industrial sector is undergoing a profound transformation, driven by trends such as Industry 4.0, the Industrial Internet of Things (IIoT), and the relentless pursuit of higher quality standards with tighter tolerances. These paradigm shifts necessitate measurement solutions that are not only highly accurate but also intelligent, integrated, and adaptable. The demand for a robust **measurement platform** is surging, fueled by:

- Digital Transformation & Automation: As factories become smarter and processes more automated, the need for real-time, automated measurement data collection and analysis intensifies. A modern **measurement platform** seamlessly integrates into automated production lines, providing crucial feedback for process control and optimization.

- Miniaturization & Nanotechnology: The shrinking size of components across various industries, from semiconductors to medical devices, demands measurement capabilities with unprecedented precision, often at the micro- or nanoscale.

- Complex Geometries & Advanced Materials: The increasing complexity of product designs and the use of new, high-performance materials (e.g., composites, additive manufactured parts) require **inspection platform**s capable of measuring intricate geometries and surface characteristics with high fidelity.

- Global Quality Standards: Strict international standards (e.g., ISO 9001, AS9100 for aerospace) necessitate rigorous quality control processes, making a reliable **platform inspection** system indispensable for compliance and market competitiveness.

- Predictive Maintenance & Quality Assurance: Leveraging data from **industrial measurement tools** for predictive analytics allows companies to anticipate potential failures, optimize maintenance schedules, and reduce downtime, significantly enhancing operational efficiency and product longevity.

Understanding the Technical Parameters of a High-Performance **Measurement Platform**

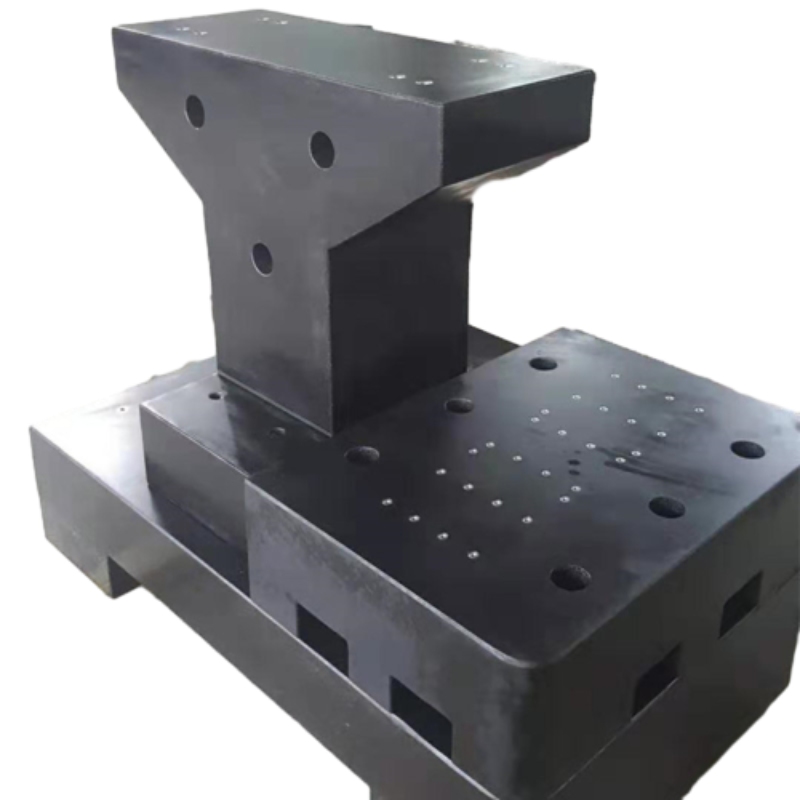

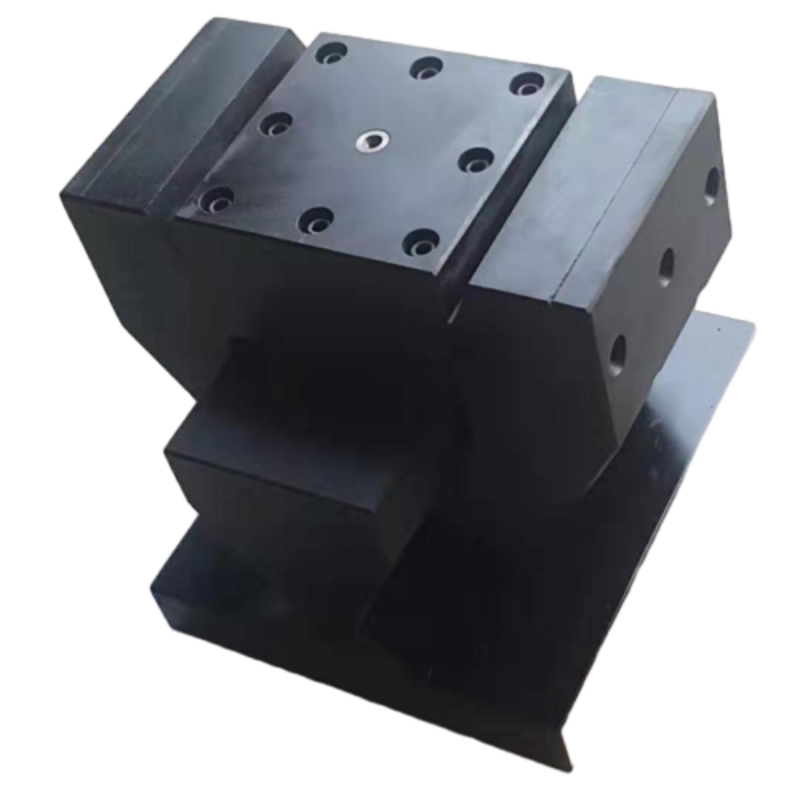

A **measurement platform** is a foundational component for various metrology systems, providing the stable, vibration-isolated base necessary for precision instruments like coordinate measuring machines (CMMs), optical comparators, laser trackers, and vision systems. Its technical specifications are paramount to its performance. Key parameters include:

- Material Composition: Typically made from high-grade cast iron (e.g., GG25, GG30), granite (black granite like Diabase or Gabbro), or specialized alloys, chosen for their superior vibration damping, thermal stability, and wear resistance. Granite platforms, in particular, offer excellent thermal stability and non-magnetic properties.

- Flatness & Parallelism: Critical for accuracy, measured in micrometers. Standard grades include DIN 876 Grade 00, 0, 1, 2, or 3. Grade 00 is the highest precision for master inspection, while Grade 1 is suitable for general precision work.

- Surface Finish: Often lapped to achieve a mirror-like finish, minimizing friction and ensuring smooth movement of instruments or measured objects.

- Load Capacity: The maximum weight the platform can support without deformation, crucial for heavy industrial components.

- Vibration Isolation: Many advanced **measurement platform**s incorporate active or passive vibration isolation systems (e.g., air springs, elastomeric isolators) to prevent external vibrations from affecting measurement accuracy.

- Thermal Stability: The ability of the material to resist expansion or contraction due to temperature fluctuations, which can significantly impact measurement results, especially over large areas.

- Dimensions & Weight: Available in a wide range of sizes, from small benchtop units to massive platforms spanning several meters, influencing their application scope and installation requirements.

Comparative Analysis: Common **Measurement Platform** Materials

The choice of material significantly influences the performance characteristics of a **measurement platform**. Below is a simplified comparison demonstrating the properties relevant to industrial applications:

| Property | High-Grade Cast Iron | Natural Granite (e.g., Black Granite) | Ceramic/Synthetic Stone |

|---|---|---|---|

| Density (g/cm³) | ~7.85 | ~3.0 | ~2.5 - 3.5 |

| Thermal Expansion Coeff. (µm/m/°C) | ~11-12 | ~6-7 | ~7-9 |

| Vibration Damping | Good | Excellent | Very Good |

| Wear Resistance | Good | Excellent (non-abrasive) | Good to Excellent |

| Corrosion Resistance | Moderate (requires coating) | Excellent | Excellent |

| Magnetic Properties | Ferromagnetic | Non-magnetic | Non-magnetic |

| Cost | Moderate | Moderate to High | High |

As seen, granite often stands out for its superior thermal stability, non-magnetic properties, and excellent vibration damping, making it a preferred choice for the most demanding precision metrology applications.

Application Scenarios & Advantages of the **Measurement Platform**

The versatility of the **measurement platform** makes it an indispensable tool across a vast spectrum of industries, where precision and reliability are non-negotiable. Its primary role is to provide a stable, controlled environment for sensitive measurement instruments, ensuring the integrity of data collected.

- Aerospace & Defense: Measuring critical aircraft components (turbine blades, fuselage sections, landing gear) where micron-level accuracy is vital for safety and performance. The **measurement platform** ensures that large, heavy components are measured accurately without deflection.

- Automotive Industry: From engine blocks and transmission cases to body panels and precision gears, the **measurement platform** facilitates rapid and accurate quality checks, supporting high-volume production lines and ensuring component interchangeability.

- Precision Manufacturing & Machining: Inspecting highly toleranced parts produced by CNC machining, additive manufacturing, or grinding processes. It serves as the foundation for verifying dimensions, form, and position.

- Electronics & Semiconductor: Providing vibration-isolated bases for micro-inspection systems used in wafer fabrication, circuit board assembly, and micro-electromechanical systems (MEMS) production, where even the slightest vibration can compromise results.

- Medical Devices: Ensuring the strict dimensional accuracy and surface finish of implants, surgical tools, and diagnostic equipment, where quality directly impacts patient safety and efficacy.

- Scientific Research & Development: Offering a stable base for optical experiments, microscopy, and material characterization, where environmental stability is paramount for reproducible results.

- Energy Sector (Petrochemical, Metallurgy, Hydropower): In sectors like **petrochemical** and **metallurgy**, large-scale components (e.g., valves, pipes, turbine parts) require robust **inspection platform**s. For **water supply and drainage** systems, verifying the precise dimensions of pumps, fittings, and large-diameter pipes ensures leak-proof and efficient infrastructure.

Key Advantages in Typical Application Scenarios:

- Enhanced Precision and Repeatability: By isolating instruments from environmental vibrations and providing a thermally stable base, the **measurement platform** drastically improves the accuracy and consistency of measurements, directly impacting product quality.

- Increased Productivity: Stable measurement conditions reduce measurement errors and the need for re-measurement, streamlining quality control processes and accelerating throughput.

- Longevity and Durability: Constructed from robust materials like high-grade cast iron or granite, these platforms offer exceptional wear resistance and a long operational lifespan, even in harsh industrial environments. For example, granite **measurement platform**s are inherently anti-corrosive and non-magnetic, making them ideal for use near magnetic fields or in environments exposed to chemicals.

- Cost Efficiency: While an initial investment, the long-term benefits of reduced scrap rates, fewer warranty claims, and optimized production processes lead to significant cost savings. The minimal maintenance required for granite platforms further reduces operational costs.

- Compliance with Standards: Facilitates adherence to stringent international metrology standards (e.g., ISO 10360 for CMMs), ensuring products meet global quality benchmarks and regulations.

Technological Edge: What Sets Our **Measurement Platform** Apart

At STR Machinery, our **Measurement Platform** (https://www.strmachinery.com/measurement-platform.html) is engineered to meet the highest standards of industrial metrology. We leverage decades of expertise in precision engineering to deliver platforms that not only meet but exceed industry expectations, providing an unparalleled foundation for your critical measurement tasks. Our technological advantages stem from:

- Superior Material Selection: We primarily utilize high-density black granite (such as Jinan Black or Shanxi Black) for our standard **measurement platform**s, known for its exceptional hardness (Mohs scale 6-7), outstanding thermal stability (coefficient of linear expansion as low as 6 x 10⁻⁶ /°C), and non-porous nature. This ensures minimal expansion/contraction with temperature changes and resistance to liquid absorption. For specific applications requiring extreme rigidity or load-bearing, we offer specialized high-grade cast iron platforms compliant with ASTM A48 Class 40B.

- Precision Manufacturing Processes: Each platform undergoes a meticulous manufacturing process, including rough grinding, fine grinding, and highly specialized hand-lapping. This multi-stage process, requiring skilled artisans, ensures extreme flatness and parallelism, meeting or exceeding international standards such as DIN 876/JIS B 7513 Grade 00, 0, or 1.

- Advanced Vibration Isolation: Depending on the application, our platforms can be integrated with passive air spring isolators or active pneumatic vibration cancellation systems. These systems are designed to attenuate vibrations across a broad frequency range (typically from 0.5 Hz to 200 Hz), providing an ultra-stable environment crucial for nanometer-level measurements.

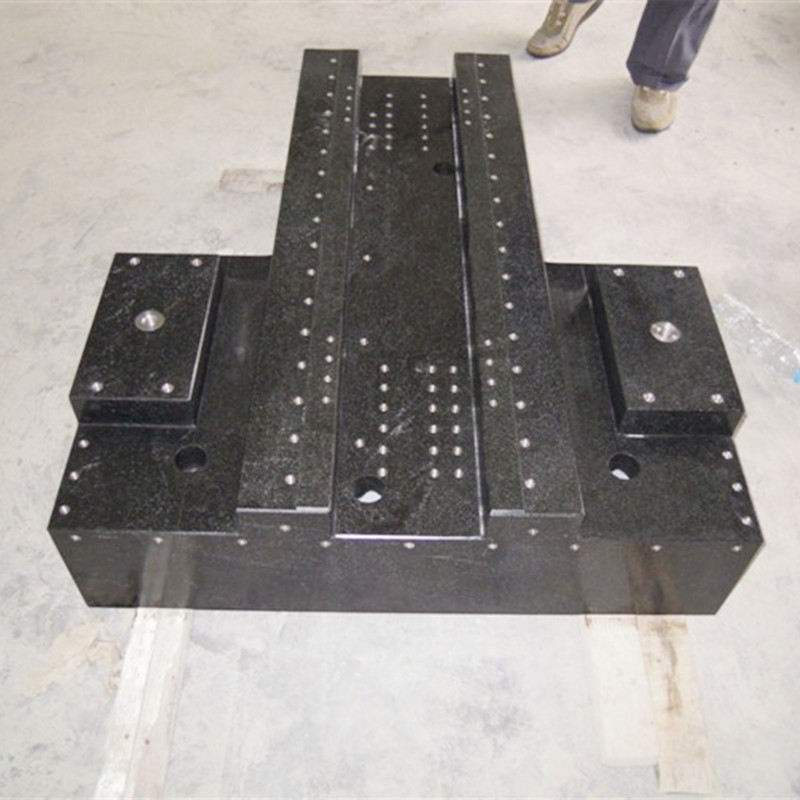

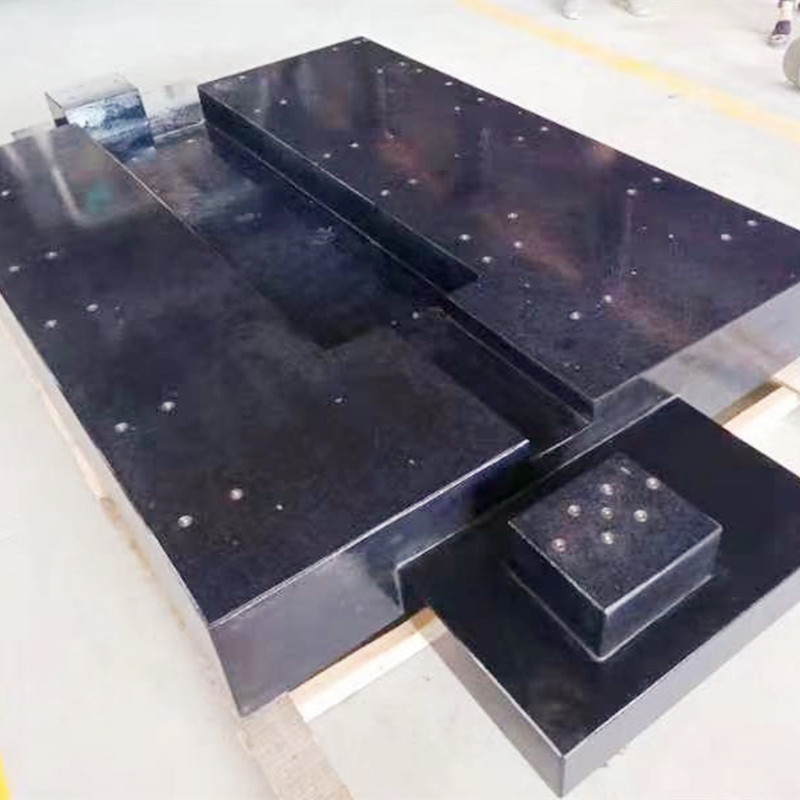

- Customization Capabilities: Recognizing that no two industrial setups are identical, we offer extensive customization options for our **measurement platform**s, including specific dimensions, threaded inserts (T-slots or helicoils), vacuum grooves, and integrated leveling feet or custom stands.

- Integrated Smart Features: For the Industry 4.0 era, our platforms can be equipped with embedded temperature sensors and data logging capabilities, providing real-time environmental monitoring. This data can be integrated into a broader manufacturing execution system (MES) for enhanced process control and traceability.

Manufacturing Process of the STR Machinery **Measurement Platform**

The creation of a high-precision **measurement platform** is an intricate process that combines advanced machinery with meticulous handcraftsmanship, ensuring every unit meets stringent quality and performance criteria. Below is a detailed breakdown of our manufacturing process for the STR Machinery **Measurement Platform** product line:

Manufacturing Process Flow: From Raw Material to Finished Product

Step 1: Raw Material Selection & Initial Inspection

Description: We begin by selecting premium-grade raw materials. For granite platforms, this involves sourcing large blocks of dense, fine-grained black granite, such as Jinan Black or Shanxi Black, known for its low porosity and uniform crystal structure. For cast iron platforms, high-strength grey cast iron (e.g., GG25 or GG30, equivalent to ASTM A48 Class 40) is procured, chosen for its excellent machinability and vibration damping properties. Each raw block or casting is thoroughly inspected for internal defects (e.g., cracks, voids) using ultrasonic testing and visual checks.

Step 2: Rough Machining / Sawing (Granite) or Casting & Stress Relieving (Cast Iron)

Granite: Large diamond wire saws or band saws are used to cut the raw granite blocks into approximate dimensions. This initial cut creates the basic shape of the **measurement platform**.

Cast Iron: Cast iron platforms undergo a precise casting process in our foundry. After casting, the blocks are subjected to a multi-stage stress-relieving heat treatment. This critical step, involving heating to specific temperatures (e.g., 550-600°C for cast iron) and controlled cooling, removes internal stresses accumulated during solidification, preventing future deformation and ensuring long-term dimensional stability, a key factor for **platform inspection** accuracy.

Step 3: Semi-Precision Grinding

Description: Both granite and cast iron platforms proceed to the semi-precision grinding phase. Large surface grinders with abrasive wheels are employed to achieve initial flatness and remove excess material, bringing the platform close to its final dimensions. For granite, this involves specialized diamond grinding wheels. This stage prepares the surface for more refined finishing.

Step 4: Fine Grinding & Lapping (Surface Finishing)

Description: This is the most critical stage for achieving the required flatness and surface finish.

Granite: The granite surfaces are meticulously fine-ground using progressively finer abrasive slurries and specialized lapping machines. The final stage involves hand-lapping by skilled technicians using precise straight edges and master reference plates. This highly iterative process is guided by auto-collimators and electronic levels to achieve micro-inch level flatness (e.g., DIN 876 Grade 00 or 0).

Cast Iron: Cast iron surfaces are precision-milled and then meticulously scraped and lapped by hand. The scraping technique, a traditional artisan skill, involves removing microscopic amounts of material to achieve a near-perfect flat surface, often checked against master surface plates using bluing compound for contact point verification.

Step 5: Drilling & Inserting (Custom Features)

Description: If the **measurement platform** requires specific features like threaded inserts (for mounting accessories or fixtures), T-slots, or through-holes, these are precisely drilled and machined at this stage. For granite, diamond core drills are used, and threaded inserts (e.g., brass, stainless steel helicoils) are epoxied into place. For cast iron, standard machining techniques are used for tapping and slotting.

Step 6: Final Cleaning & Inspection

Description: Each completed **measurement platform** undergoes a thorough cleaning process to remove any residual abrasives, oils, or dust. A final, comprehensive inspection is then performed in a temperature-controlled metrology lab. This inspection includes:

- Flatness Measurement: Using highly precise electronic levels, auto-collimators, laser interferometers, or CMMs (Coordinate Measuring Machines) to verify compliance with specified flatness tolerances (e.g., ISO 8527, ANSI B89.3.7).

- Surface Finish Measurement: Using profilometers to ensure the required surface roughness (Ra) is achieved.

- Dimensional Verification: All critical dimensions are checked against engineering drawings.

- Visual Inspection: Checking for any cosmetic defects or imperfections.

Step 7: Packaging & Shipping

Description: Once certified, the **measurement platform** is carefully packed to protect its precision surface during transit. This often involves custom-built wooden crates, protective covers, and moisture-absorbing desiccants to prevent rust or damage. Each platform is delivered with a certificate of calibration.

Throughout this process, stringent quality control measures are in place, adhering to international standards such as ISO 9001:2015 for quality management and ANSI B89.3.7 for surface plate (a type of **measurement platform**) specifications. Our commitment to these standards ensures every **measurement platform** leaving our facility offers exceptional dimensional stability, superior vibration damping, and an extended service life (typically 20+ years under normal operating conditions), reducing the need for frequent replacements and recalibrations. This meticulous approach directly contributes to the energy efficiency of the overall measurement process by minimizing error and rework. Furthermore, for applications in corrosive environments, the inherent chemical inertness of granite or specialized coatings on cast iron provide robust anti-corrosion properties.

Manufacturer Comparison: Why Choose STR Machinery for Your **Measurement Platform**?

The market offers various manufacturers of **industrial measurement tools**, each with unique strengths. When considering a **measurement platform**, it's crucial to evaluate factors beyond just price. STR Machinery stands out due to a blend of superior quality, advanced technology, and unwavering customer support.

| Feature/Criteria | STR Machinery (Product: Measurement Platform) | Competitor A (Generic) | Competitor B (Generic) |

|---|---|---|---|

| Material Quality & Grade | Premium Jinan Black/Shanxi Black Granite (DIN 876 Grade 00/0), ASTM A48 Class 40B Cast Iron | Standard Black Granite (DIN 876 Grade 1/2), Grey Cast Iron | Mixed Granite Grades, Basic Cast Iron |

| Flatness Tolerance Offered | Up to DIN 876 Grade 00 (0.0015mm/1000mm) | Up to DIN 876 Grade 1 (0.003mm/1000mm) | Typically DIN 876 Grade 2/3 (0.006-0.012mm/1000mm) |

| Vibration Isolation Options | Passive & Active Air Spring Systems, Custom Tuned | Basic Passive Rubber Mounts or None | Limited Passive Options |

| Customization & Integration | Extensive: Custom dimensions, T-slots, inserts, sensor integration, MES compatibility | Limited standard sizes, few customization options | Mostly off-the-shelf |

| Manufacturing & Calibration Standards | ISO 9001:2015, ANSI B89.3.7, Traceable Calibration Certificates | Internal standards, basic calibration | Variable |

| Customer Support & Warranty | 5-Year Structural Warranty, Global Technical Support, On-site Calibration Services | 1-3 Year Basic Warranty, Regional Support | Limited Warranty, Basic Support |

| Industry Certifications | CE, ISO 9001, Partnered with leading metrology institutes | Basic CE | None stated |

Our dedication to stringent quality control, leveraging advanced machining technologies alongside traditional hand-finishing techniques, ensures that every **measurement platform** we produce is a testament to precision engineering. Furthermore, our comprehensive after-sales support and global network guarantee that your investment is protected and your operations run smoothly, making STR Machinery a reliable partner for your critical **platform inspection** needs.

Custom Solutions & Tailored **Measurement Platform** Design

In the realm of advanced manufacturing and scientific research, standard solutions often fall short of unique requirements. STR Machinery excels in providing bespoke **measurement platform**s tailored to specific industrial needs. Our approach involves a collaborative process from concept to delivery:

- Initial Consultation & Requirement Analysis: Our engineers work closely with your team to understand the specific application, environmental conditions, desired precision levels, instrument payload, and integration requirements. This includes evaluating the type of measurement (e.g., optical, tactile, laser scanning), space constraints, and budget.

- Design & Engineering: Based on the analysis, we develop detailed CAD designs for your custom **measurement platform**. This includes material selection (e.g., specific granite type, cast iron grade), dimensional configurations, integration points for CMMs or other metrology equipment, and vibration isolation system design. We utilize finite element analysis (FEA) to simulate structural integrity and thermal behavior under various load conditions, ensuring optimal performance.

- Prototyping & Testing (if required): For highly complex or novel applications, we can develop prototypes and conduct rigorous testing in our advanced metrology lab to validate design parameters and performance specifications before full-scale production.

- Precision Manufacturing & Quality Assurance: The custom platform undergoes the same stringent manufacturing and quality control processes as our standard products, including multi-stage grinding, hand-lapping, and comprehensive calibration in a temperature-controlled environment. Every custom **measurement platform** is delivered with a calibration certificate conforming to international standards (e.g., DIN 876).

- Installation & Commissioning Support: We provide expert guidance and, if required, on-site support for the installation and commissioning of your custom **measurement platform**, ensuring seamless integration into your existing metrology setup.

Whether you require an extra-large **inspection platform** for aerospace components, a specialized non-magnetic **measurement platform** for scientific research, or a vibration-isolated base for an electron microscope, STR Machinery has the expertise and manufacturing capabilities to deliver a solution that precisely meets your technical and operational demands. Our commitment to customized solutions ensures that you receive an **industrial measurement tool** that perfectly aligns with your unique challenges, maximizing your measurement efficiency and accuracy.

Application Cases & Customer Success Stories

The reliability and precision of STR Machinery's **Measurement Platform** have been proven across diverse industrial sectors, delivering tangible benefits to our clients. Here are a few illustrative examples:

Case Study 1: Automotive Powertrain Manufacturing

Client: A leading global automotive manufacturer.

Challenge: The client needed to upgrade their quality control stations for high-volume production of engine blocks and cylinder heads. Their existing platforms were prone to vibration and thermal expansion, leading to inconsistent CMM measurements and production bottlenecks. They required a large **measurement platform** (3000mm x 2000mm) capable of handling heavy components while maintaining sub-micron accuracy for critical bore and surface flatness checks.

Solution: STR Machinery designed and supplied two custom-sized **measurement platform**s made from high-density Shanxi Black granite, each featuring integrated active pneumatic vibration isolation systems. The platforms were manufactured to DIN 876 Grade 00 flatness specifications and equipped with a network of precision-machined threaded inserts for flexible fixture mounting.

Results: Post-installation, the client reported a 35% reduction in measurement cycle time due to enhanced stability and reduced rework. The consistency of CMM measurements improved by over 40%, leading to a significant decrease in false rejects and an overall improvement in product quality. The durability of the granite **platform inspection** system also led to reduced maintenance costs.

Case Study 2: Medical Device Component Production

Client: A specialist manufacturer of orthopedic implants.

Challenge: Producing highly intricate and tiny implant components (e.g., screws, plates) required ultra-high precision vision system measurements. The production environment, however, introduced micro-vibrations from nearby machinery, affecting measurement accuracy and reproducibility. They needed a compact yet extremely stable **measurement platform** for their cleanroom facility.

Solution: We provided a compact, benchtop **measurement platform** (800mm x 600mm) constructed from precision-lapped Jinan Black granite, specifically optimized for optical metrology. This platform was mounted on an independent passive air-spring isolation table, specifically tuned to filter out high-frequency vibrations common in their facility.

Results: The implementation of our **measurement platform** resulted in a 60% improvement in measurement repeatability for critical dimensions on small components, directly contributing to compliance with stringent FDA regulations for medical devices. The client noted increased confidence in their quality data, leading to faster product validation and market entry.

Customer Testimonial:

"STR Machinery's **measurement platform** has transformed our inspection capabilities. We saw an immediate and noticeable improvement in the stability of our optical measuring equipment. Their technical team was incredibly knowledgeable and supportive throughout the customization and installation process. It's a truly reliable **industrial measurement tool** that has paid for itself in reduced errors and increased throughput." - Quality Assurance Manager, Large Aerospace Component Manufacturer

EEAT Standards and Trustworthiness

STR Machinery is committed to upholding the highest standards of Expertise, Experience, Authoritativeness, and Trustworthiness (EEAT) in every aspect of our operations and product offerings, particularly concerning our **Measurement Platform**s.

Expertise: Deep Industry Knowledge

Our engineering team comprises specialists with decades of experience in metrology, material science, and precision manufacturing. We regularly publish insights and participate in industry forums to share our knowledge on topics ranging from thermal stability in granite to advanced vibration isolation techniques for **platform inspection**. Our expertise is reflected in the detailed technical specifications and performance guarantees of our **measurement platform**s, ensuring that we understand and address the intricate challenges faced by our clients.

Experience: Proven Track Record & Customer Feedback

With over 25 years in the precision engineering industry, STR Machinery has successfully deployed thousands of **measurement platform**s globally. Our product usage scenarios span from small-batch prototyping labs to high-volume automotive production lines and critical aerospace manufacturing facilities. We actively solicit customer feedback through surveys and direct communication, using insights to continuously refine our product designs and service offerings. The application cases above are just a glimpse of our extensive experience in solving complex measurement challenges.

Authoritativeness: Certifications, Partnerships & Industry Recognition

Our authority in the field is underscored by:

ISO 9001:2015 Certified

Adherence to international quality management standards.

CE Mark Compliant

Ensuring products meet EU safety, health, and environmental protection requirements.

Accredited Metrology Lab

Our in-house calibration lab is accredited to international standards, providing traceable calibration certificates.

Industry Association Member

Active participation in leading metrology and manufacturing associations.

We also cite recognized industry standards such as DIN 876 for granite surface plates and ANSI B89.3.7 for cast iron surface plates in our product documentation and technical specifications, providing a clear benchmark for our quality.

Trustworthiness: Transparency & Support

We build trust through transparent practices and robust support systems:

- FAQ Module: Providing clear and concise answers to common technical and operational questions.

- Delivery Cycle: Our standard delivery cycle for a custom **measurement platform** ranges from 8 to 12 weeks, depending on complexity, with specific timelines communicated upfront and tracked via project management software. For standard sizes, lead times can be as short as 4-6 weeks.

- Quality Assurance & Warranty: Each **measurement platform** undergoes rigorous final inspection, including laser interferometer flatness mapping. We offer a comprehensive 5-year structural warranty on our granite and cast iron **measurement platform**s, covering material defects and manufacturing errors. This is a testament to our confidence in product durability.

- Customer Support: Our dedicated customer support team is available globally for technical assistance, installation guidance, and post-warranty service. We offer various support packages, including on-site calibration and preventative maintenance agreements.

Professional FAQ on **Measurement Platform**s

What materials are commonly used for a **measurement platform** and why?

The most common materials are high-grade black granite (e.g., Jinan Black, Shanxi Black) and high-quality cast iron (e.g., GG25, GG30). Granite is preferred for its excellent thermal stability, non-magnetic properties, superior vibration damping, and resistance to corrosion and wear. Cast iron offers high rigidity, good vibration absorption (though less than granite), and allows for the integration of T-slots directly into the casting for heavy-duty applications. Both are chosen for their intrinsic stability and ability to be machined to extremely precise flatness tolerances, crucial for any **inspection platform**.

What are the key inspection standards for a **measurement platform**?

The primary international standards for a **measurement platform** (often referred to as surface plates) include DIN 876 (German Standard), JIS B 7513 (Japanese Industrial Standard), and ANSI B89.3.7 (American National Standard). These standards define tolerance grades for flatness (e.g., Grade 00, 0, 1, 2, 3), specifying the maximum permissible deviation from perfect flatness over the entire surface. Calibration is typically performed in a temperature-controlled environment (20°C ± 1°C) using auto-collimators, electronic levels, or laser interferometers.

How does vibration isolation benefit a **measurement platform**?

Vibration isolation is crucial because external vibrations (from machinery, traffic, even foot traffic) can significantly compromise the accuracy of sensitive metrology equipment mounted on the **measurement platform**. Isolation systems (passive air springs, active pneumatic systems) dampen these vibrations, providing a stable, quiescent environment. This leads to more precise, repeatable, and reliable measurements, particularly vital for high-magnification optical systems, CMMs, and nanometer-scale **platform inspection**.

What is the typical lifespan of a **measurement platform** and how is it maintained?

A high-quality **measurement platform**, especially one made from granite, can last for 20 years or more with proper care. Cast iron platforms also offer long lifespans with appropriate maintenance. Maintenance involves regular cleaning with non-abrasive cleaners, avoiding heavy impacts or dragging objects across the surface, and periodic recalibration (typically every 1-5 years depending on usage and required precision). Protecting the surface when not in use with a cover is also recommended. This ensures the longevity and accuracy of your **industrial measurement tool**.

Can a **measurement platform** be customized for specific applications?

Yes, absolutely. Customization is a key offering for advanced **measurement platform** manufacturers like STR Machinery. This can include bespoke dimensions, specific thicknesses, the addition of threaded inserts (T-slots, steel bushings, helicoils) for fixturing, vacuum hold-down grooves, integrated air bearing surfaces, or custom stands/bases with leveling capabilities. Such customization ensures the platform seamlessly integrates into unique manufacturing or research setups, making it a truly versatile **inspection platform**.

What role does thermal stability play in the accuracy of a **measurement platform**?

Thermal stability is paramount. Materials expand and contract with temperature changes. If the **measurement platform** itself expands or contracts unevenly, or at a different rate than the measured object or the measuring instrument, it introduces significant errors. Granite, with its very low coefficient of thermal expansion, is highly stable, minimizing dimensional changes due to temperature fluctuations. This ensures that measurements taken at different times or under slight temperature variations remain consistent and accurate, supporting robust **platform inspection** protocols.

How does a **measurement platform** contribute to energy efficiency?

While a **measurement platform** itself does not consume significant energy, its precision and stability contribute to overall energy efficiency within an industrial process by:

- Reducing Rework and Scrap: Accurate measurements prevent the production of faulty parts, thereby saving raw materials, energy, and labor associated with remanufacturing.

- Optimizing Production Processes: Reliable data from the **measurement platform** enables tighter control over manufacturing processes, reducing material waste and optimizing machine run times.

- Extending Product Lifespan: Ensuring components meet design specifications leads to more durable and reliable end products, reducing the need for replacements and associated energy consumption over their lifecycle.

Conclusion: The Future of Precision with STR Machinery's **Measurement Platform**

As industries worldwide continue their trajectory towards higher precision, greater automation, and increasingly complex designs, the role of a reliable and accurate **measurement platform** becomes ever more critical. STR Machinery's commitment to innovation, superior material science, and meticulous craftsmanship ensures that our **measurement platform** stands as the cornerstone of advanced metrology. From foundational stability in research laboratories to the rigorous demands of high-volume manufacturing, our platforms provide the essential environment for capturing critical data with unparalleled accuracy.

We invite you to explore how our custom-engineered solutions can elevate your quality control processes, enhance your product reliability, and drive your operational efficiency. Partner with STR Machinery, and build your future on a foundation of precision.

References & Further Reading

For more in-depth understanding of metrology standards and practices, we recommend consulting the following authoritative resources:

- "Fundamentals of Dimensional Metrology" by Ted Busch - Provides a comprehensive overview of measurement principles and practices. (Placeholder Link: https://www.sme.org/store/books/fundamentals-of-dimensional-metrology)

- ISO 9001:2015 - Quality management systems — Requirements. (Placeholder Link: https://www.iso.org/standard/62085.html)

- ANSI B89.3.7 - 2013: Surface Plates. (Placeholder Link: https://www.asme.org/codes-standards/products/dimensional-metrology/b8937-2013-surface-plates)

- NIST (National Institute of Standards and Technology) - Provides extensive research and guidelines on measurement science. (Placeholder Link: https://www.nist.gov/programs-projects/manufacturing-measurement-metrology)

- Industry Forum on Precision Engineering & Nanotechnology. (Placeholder Link: https://www.aspe.net/)

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS